-

I also see now from your M122 that you're running on the LPC port. I'll move this to the LPC forum.

-

@deathbydeltabot said in Strange overextrusion with E3D Cyclops+:

config.g

First thing I would suggest is tunning the heaters.....

-

@Phaedrux I don't think I can do a cold pull with this hotend. There isn't a direct path from the heat break to the nozzle. What I've done before is heat up the hotend and remove the nozzle then pull out the plastic from the nozzle with tweezers. Then cool the hotend down to like 170 or so and slowly extruder plastic from both extruders to flush out the heater block. Would that be good enough?

-

@DIY-O-Sphere I did a PID tune on both the hotend and the bed a couple days ago but I'll do another one.

-

@deathbydeltabot

Found it... You use M501

Maybe check config.g.override for the PID values. -

@deathbydeltabot Are you retracting the unused filament path as well as the used one what I suspect is happening is that you secondary filament is in contact with the heat and as such is hydrolysing which will result I believe in a periodic splurge.

Ian aka @Deckingman is the expert on mixing hotness (Which is what the Cyclops is).

-

@Dougal1957 said in Strange overextrusion with E3D Cyclops+:

@deathbydeltabot Are you retracting the unused filament path as well as the used one what I suspect is happening is that you secondary filament is in contact with the heat and as such is hydrolysing which will result I believe in a periodic splurge.

He wrote, he's mixing both 50/50

But I'm on the same path...it seems to me that one of the extruders fail at retraction occasionally.

Try to reduce retraction speed. -

@DIY-O-Sphere

I have these in my config-override.g

M307 H0 A127.6 C574.1 D0.5 S1.00 V0.0 B0

M307 H1 A469.2 C188.8 D10.2 S1.00 V0.0 B0@Dougal1957

I've read @deckingman's blog, it has been incredibly useful! I don't know where the similarities between the Diamond and Cyclops+ end though. I think the blog is where I got the 3000mm/min for firmware retraction.

I turned down the retraction speed to what @deckingman is using (https://forum.duet3d.com/topic/9092/bondtech-bmg-owners-what-are-your-accel-and-jerk-settings/9)M207 S5.0 F1800 Z0.3

M207

Tool 0 retract/reprime: length 5.00/5.00mm, speed 30.0/30.0mm/sec, Z hop 0.30mm

Tool 1 retract/reprime: length 5.00/5.00mm, speed 30.0/30.0mm/sec, Z hop 0.30mm

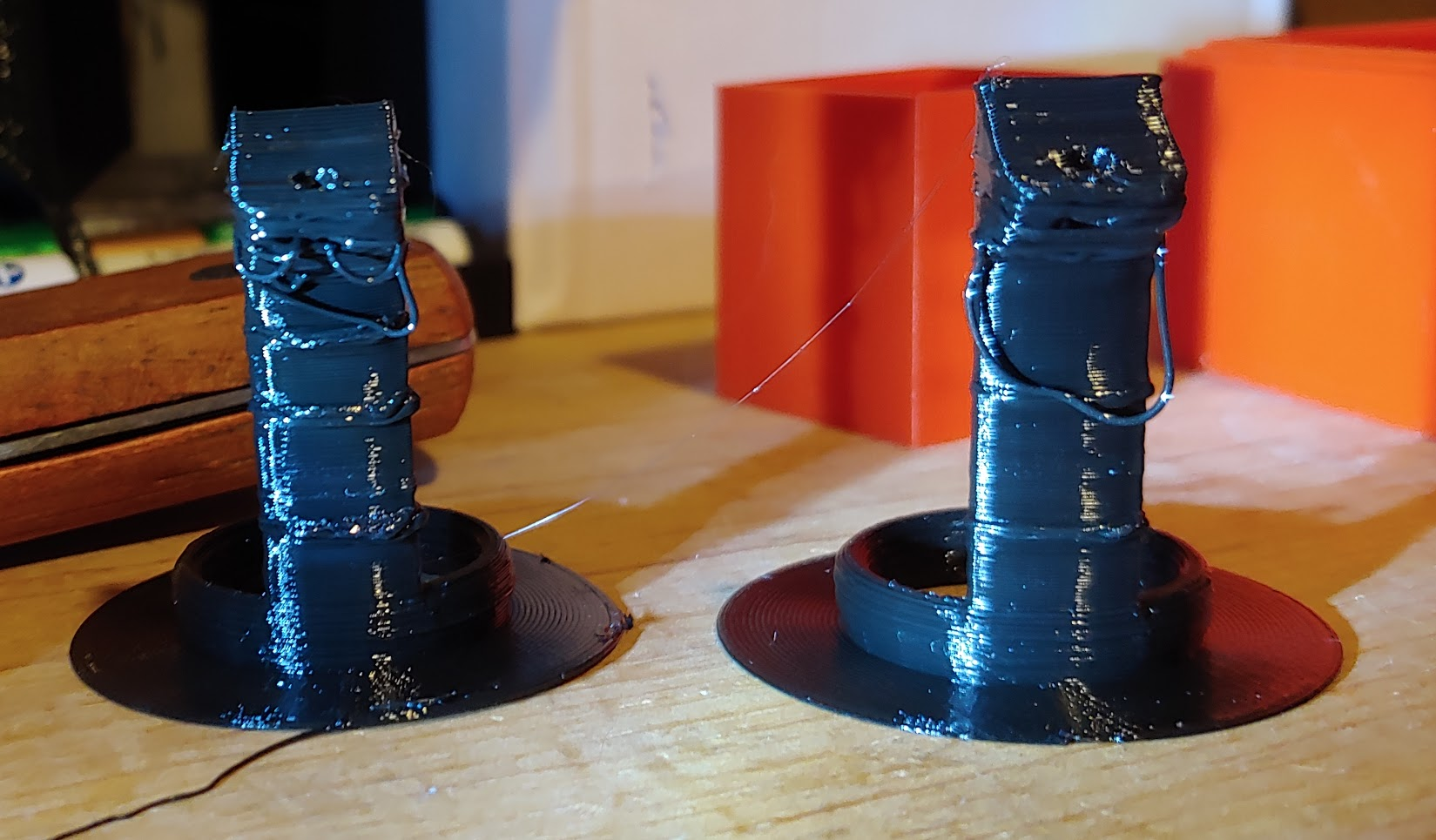

Tool 2 retract/reprime: length 5.00/5.00mm, speed 30.0/30.0mm/sec, Z hop 0.30mmIt does seem to have helped but still a ways to go. 3000mm/min on left 1800mm/min on right.

Here are some other relevant settings for the extruder:

M566 X600 Y600 Z600 E1200:1200 ; set maximum instantaneous speed changes (mm/min)

M203 X12000 Y12000 Z12000 E12000:12000 ; set maximum speeds (mm/min)

M201 X3000 Y3000 Z3000 E3000:3000 ; set accelerations (mm/s^2)I tensioned the screw on the BMGs as recommended by Bondtech. Screw all the way in then back it off 1-2 turns. In my case I did 1.5 turns.

-

Since messing with retraction had some impact I decided to see what it would look like with retraction disabled. I issued this command:

M207 S0 F1800 Z0

And this was result. Better but still something going on.Left M207 S5.0 F3000 Z0.3

Middle M207 S5.0 F1800 Z0.3

Right M207 S0 F1800 Z0

-

@deathbydeltabot I saw my name mentioned. I've mothballed my machine because I have reached the end of my tether with all the firmware problems with RRF3 which I have been battling with for 18 months or more. Maybe I'll pick it up again in 6 months or a year but I'm currently looking at alternatives to Duet/RRF.

I'm using my phone right now, but I'll fire up my pc later and look through your config to see if I can come up with anything.

-

I ran a few more tests.

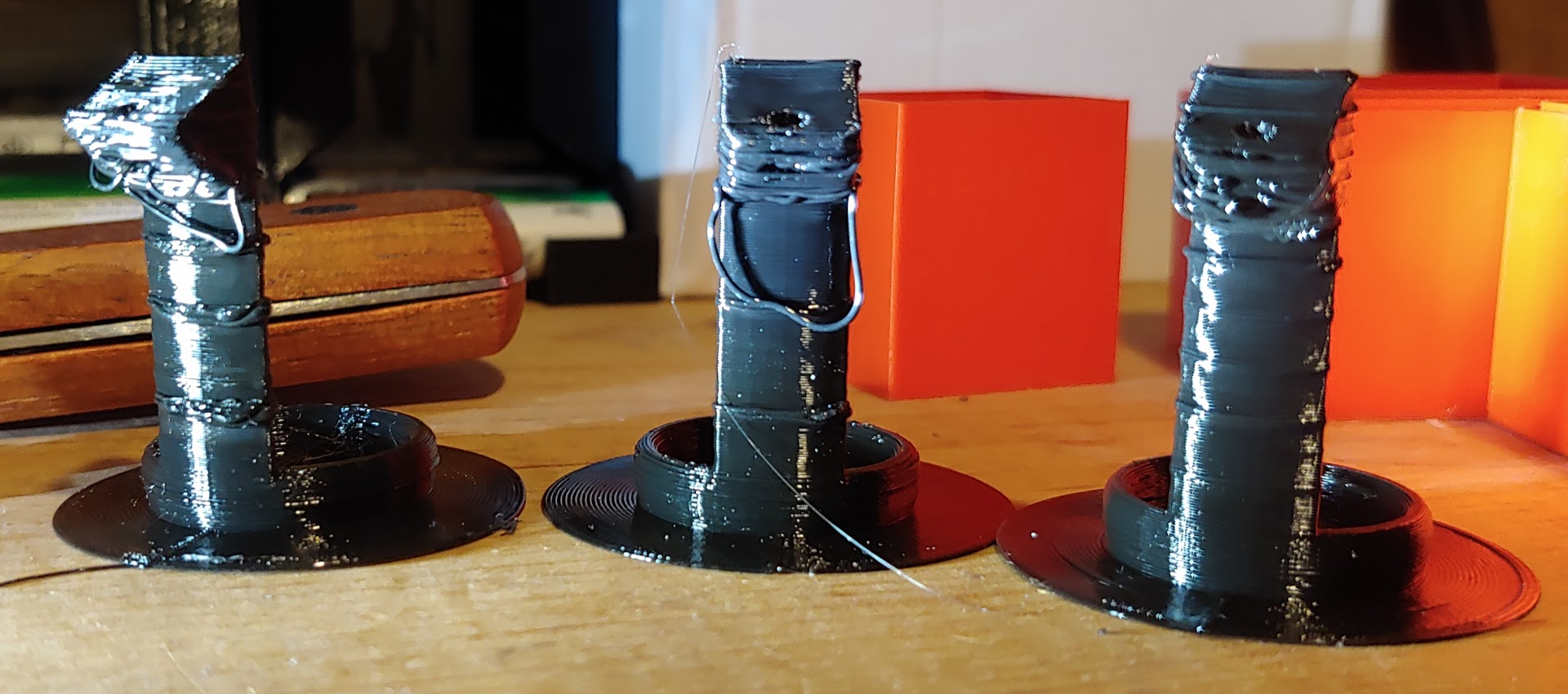

Test A) Disable mixing on T0 so only one side is retracting with extruder 0. Then print the object with T0 only. Loaded with filament "B1"

Test B) Same as A but T1 and extruder 1 and filament "B2"

Print A came out very clean, no issues. Print B looked awful. Worse than the previous images posted here. I messed with various things such as the stepper driver, PTFE tube etc until I noticed the brim on print B was translucent but the print from A was completely opaque (visible in image below). So I moved filament B1 to extruder 1. Print came out fine! I didn't even consider filament B2 being bad since I'd printed probably 95% of the spool without issues (that I noticed). So that's going into the trash.

Test C) I put a spool of white into T0/E0 and mixed 50/50 so retractions retracted both filaments

I thought I had it solved until I looked at print C. I am not sure if I have fixed the problem or if the problem is manifesting differently. The mixing looks great on the brim (I like the color bias) but further up the object the colors are segmented. Like it prints black for a few layers then white for the next few then black again. Especially bad at the top. If this is simply how "mixing" works for this hotend I'm good with that, I'm not sure what I should expect.

Left test B, Middle test A, Right test C

-

@deathbydeltabot Here is my best guess. You are getting a partial blockage on one input. It might be caused by too much retraction - looks like you are using 5mm which is a lot. It could be that molten filament is being drawn up past the heat break where it cools and solidifies. Or it might just be caused by heat creep. Do you have even cooling over both sides of the hot end? Is that cooling adequate? Anyway, assuming that one filament is swelling and "sticking" inside the PTFE liner, then it won't be moving forward as much as the other filament. Over time, being PLA, it will hydrolyse (become more and more runny) until eventually it will suddenly some out as one big runny blob. This would then manifest itself as the over extrusion that you have witnessed. Once that "blob" has run out, the process of slowly hydrolysing starts again and you get a repeat of that behaviour.

It's just a guess but IMO it's a plausible explanation for what you are seeing. PLA swelling and then hydrolysing when held at print temperature without moving forward is a very real phenomenon.

If you can, try printing with PETG just to see if that makes a difference and to prove a point. PETG has a high Tg so does not swell so much due to heat creep, but more importantly, it does not hydrolyse over time.

You can also try printing at lower temperature and/or high speed - both of which might help.

In my experience, mixing hot ends tend to print better at lower temperatures than one expect - even 5 - 10 degrees lower than what a manufacturer might recommend. Print a temperature tower to find what's best for your hot end. I usually end up with around 185 degC for PLA with my mixing hot ends. Because you are using a mixing ratio of 0.5:0.5, then each filament will travel though the hot end at half the speed of a single filament. So the filament spends twice as long in the hot end which might be why a lower temperature works better (and it will also help with heat creep if that is indeed an issue).

Finally, you need to sort out some part cooling to deal with that overhang (and lowering the temperature might also help with that too). -

@deckingman Thank you for taking a look. I reluctantly settled on 5mm retraction. 3mm was sufficient for one of those retraction tests but in practice would still produce really bad stringing. I need to revisit this. For cooling I have the single fan on the front of the heatsink as provided by E3D. I'm not sure how to know if that is providing adequate cooling or not. I'm under the assumption that E3D knows what they are doing when they include that fan (although the connector on their thermistors doesn't inspire confidence). I've been looking out for jams due to filament getting stuck in the heatbreak but none to report (yet).

Printing at 190 gave really bad stringing but 200 eliminated them. 195 might be the sweet spot though. I do have a couple rolls of PETG to try. I've been meaning to see how it works differently anyway.

I totally agree my part cooling is not up to the job. I have a 4010 radial fan, anything bigger is going to be a challenge to fit onto the effector. I've spun my wheels for months trying to find the right way to direct air around such a large heater block. I can't tell if it's the way the air is directed or the total air flow that's at fault. Maybe I should ask E3D what part cooling solution they recommend. To try and combat the overhang with subpar part cooling I've printed as low as 180 and it didn't seem to make a difference. I don't understand why.Thank you for the effort you put into your blog, it's been invaluable.