stepper precision

-

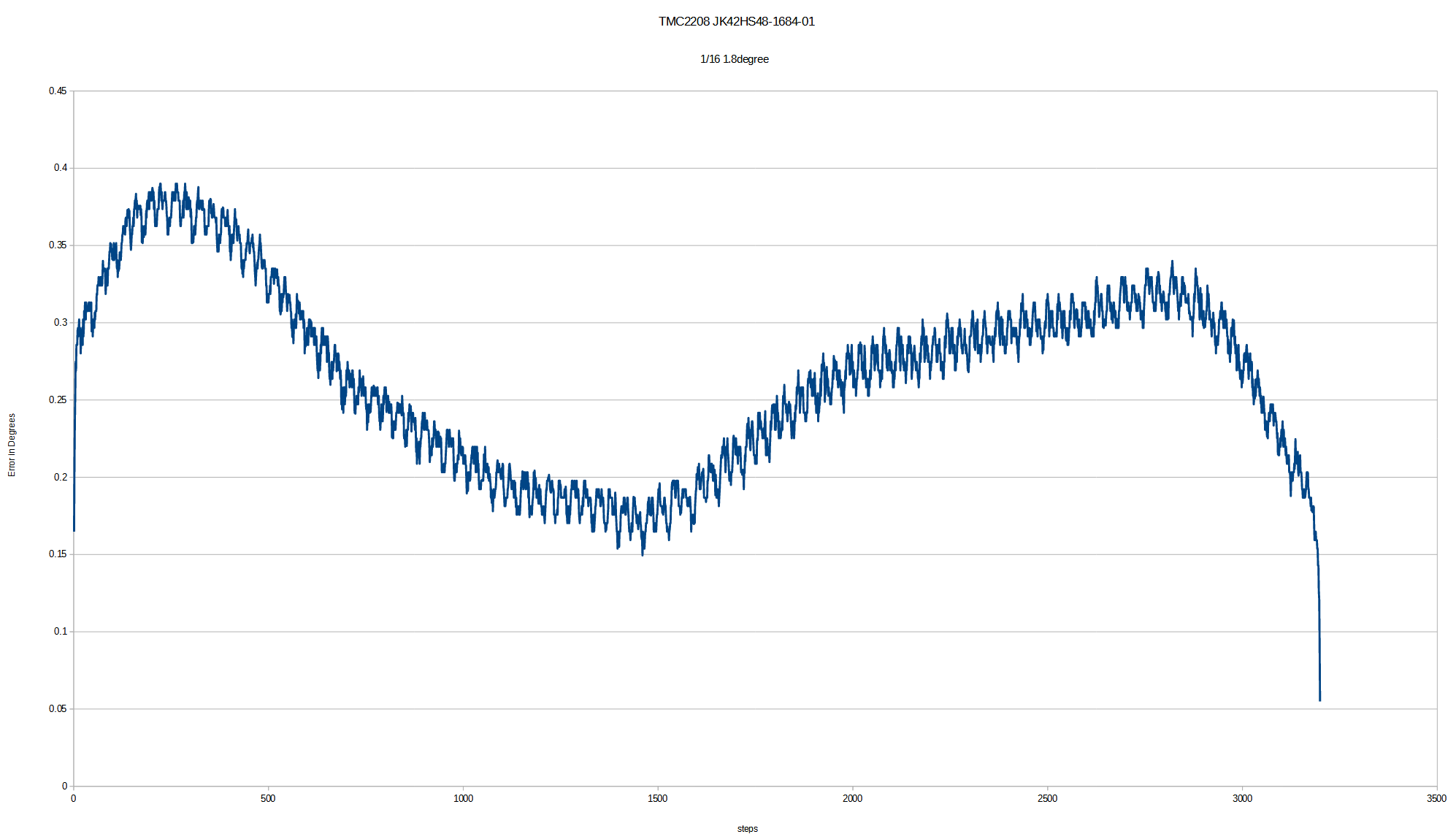

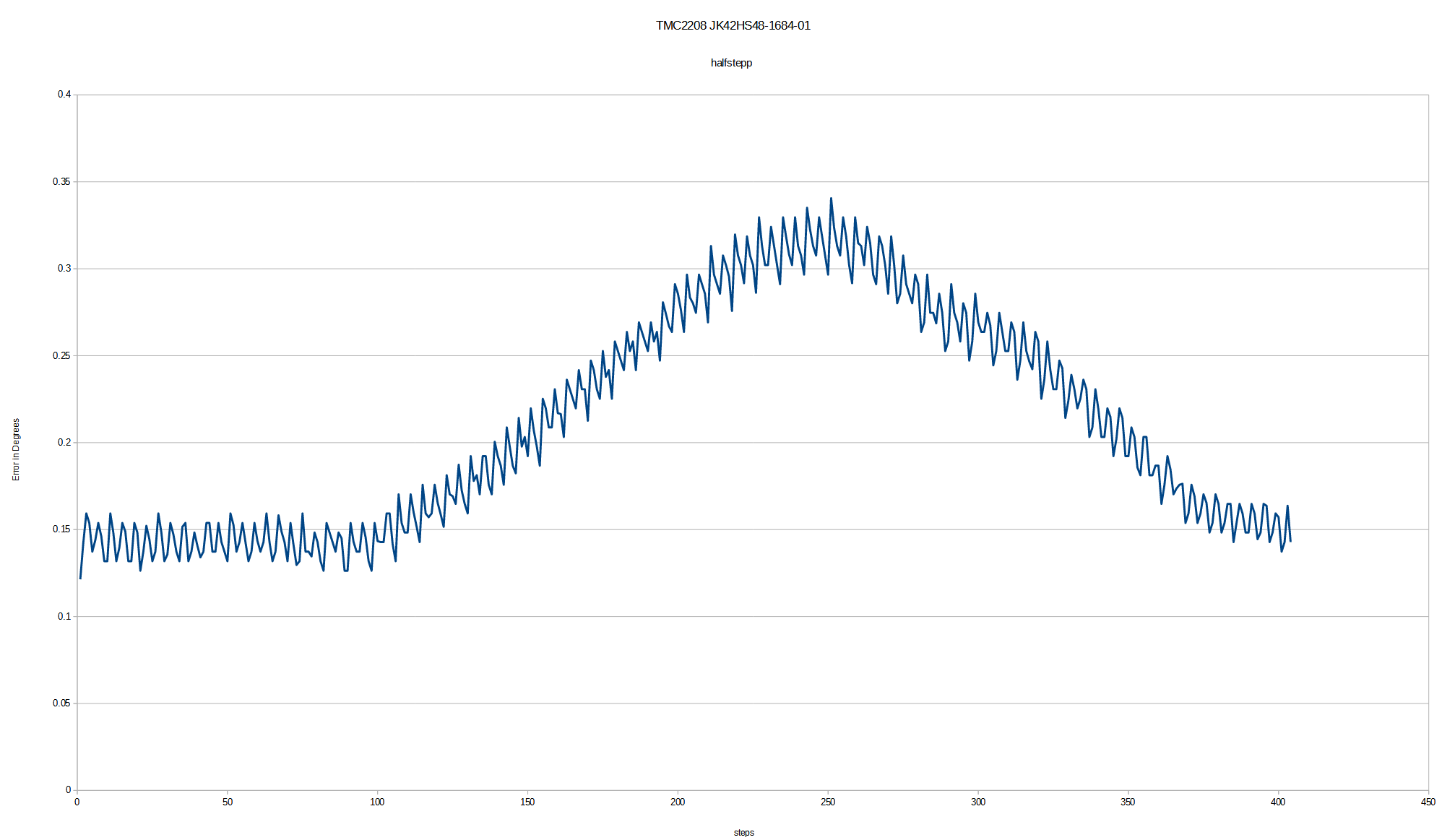

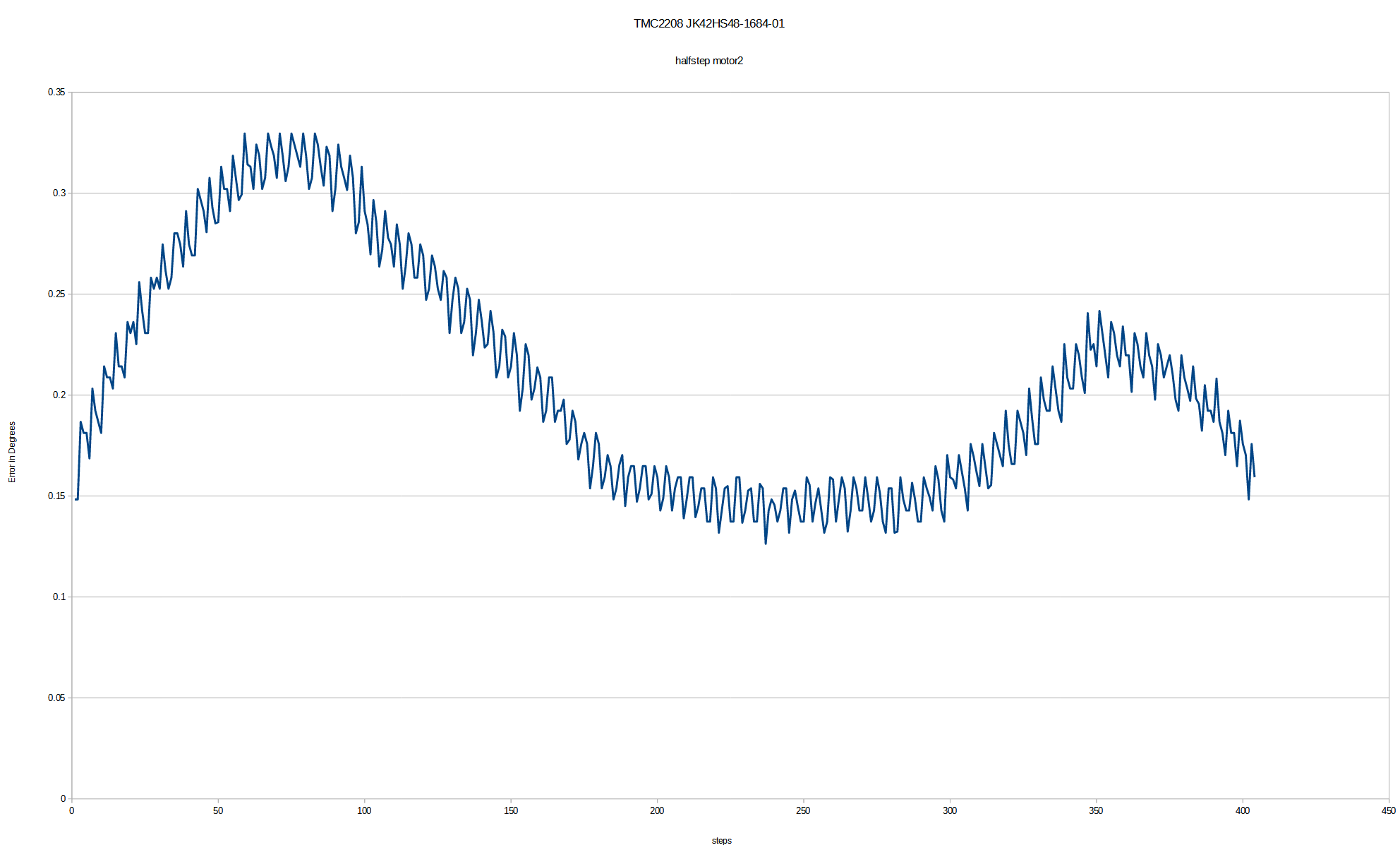

second DPM motor

-

I found the box with the stepper/encoder and controller!

Now I just need to find the time - still looking for that.

Frederick

-

-

@arhi Are you sure you're calibrating the controller every time?

It looks like going forward, you get 0.5-degree of error, but going backwards, you get MUCH LESS error. Under 0.1 degree

Maybe try going three turns forward and then three turns backwards just in case it take one-turn to calibrate or something.

-

@alankilian said in stepper precision:

@arhi Are you sure you're calibrating the controller every time?

For S42B - yes, I am sure, I calibrated every time when running closed loop. I don't see a point as nothing physically changed in the setup between runs but I still run the calibration every time before I run the test as calibration is rather quick (it goes full circle one direction and then full circle other direction) ... anyhow notice these lasts graphs are with TMC2208, nothing to calibrate there

-

same motor as earlier only run again to see how "repeatable" this is (not very)

-

JK42HS48-1684-01

-

-

This looks interesting!

do you also think, that comparing one and the same motor once in Fullstep and once in 1/16microsteps, one session with one without microplying to 256 would also tell a bit of how much those features within the driver do contribute to the error?

Great work! Keep it up!

-

@LB said in stepper precision:

This looks interesting!

do you also think, that comparing one and the same motor once in Fullstep and once in 1/16microsteps, one session with one without microplying to 256 would also tell a bit of how much those features within the driver do contribute to the error?

Well I only have 2208 and there I cannot turn on/off the 256 interpolation, I can only play with MS0 and MS1 .. so change 1/2, 1/8, 1/16 ... since I was looking at testing motors and not drivers the idea is to use single driver on all motors, introducing new driver and spi control would require a new hat with spi interface too and that all requires time

... I just managed to find the stepper with encoder but the driver is still missing for that test .. I'm now going to run this last JK42HS48-1684-01 with few more microstepping options on the 2208 before I turn this place upside down finding that driver

... I just managed to find the stepper with encoder but the driver is still missing for that test .. I'm now going to run this last JK42HS48-1684-01 with few more microstepping options on the 2208 before I turn this place upside down finding that driver -

the graphs (and data behind them) so far:

encoder-readings.odsWhat's presented in these graphs so far and in this ods is

move full circle forward

move then full circle backwards

record both positions in the array

display difference of position readout as error -

-

These graphs are all very interesting (as if I understand what you are doing) but what is the real world application for this information?

Thanks.

Frederick

-

-

@fcwilt said in stepper precision:

These graphs are all very interesting (as if I understand what you are doing)

This ones are showing position error returning to same location running motor backwards ... motor goes full circle one direction, then returns back to beginning and graph show difference in position at each location

but what is the real world application for this information?

I'm doing this tests for two main reasons

- comparing different motors I have to see how they behave

- looking at step distribution inside a single step

These graphs so far are just the "end of the test" and give me some general idea about how crappy all these motors are, and I'm actually just "done with them" as I don't have any more free motors to test. The one I was very interested to test is a bulgarian closed loop motor (clone of a prc clone of usa closed stepper driver) but while I managed yesterday to find the motor I can't find the bloody driver nowhere

so ..

so ..So now I will see if I can extract the actual data I wanted to extract at the beginning (microstepping location error) but this will take bit more time

-

@arhi Thanks for the info.

Do you have any reason at this point to think that a "premium" (meaning real expensive I suppose) stepper would perform better?

And if it did would you be able to say why it did? Quality of materials? Quality of construction?

As to a closed loop system how much would you have to spend to get a system of interest to you?

The setup I got was just for fun, from STEPPERONLINE, and it was only $100 so if it turns out to be crap I will not be surprised or upset. I wasn't prepared to spend a lot for just having some fun.

Thanks.

Frederick

-

@fcwilt said in stepper precision:

Do you have any reason at this point to think that a "premium" (meaning real expensive I suppose) stepper would perform better?

I don't know enough about steppers to have any reasoning about that. I wanted to see how good/bad the S42B is, to do few tests with normal steppers and test this bulgarian copy of a copy that I probbly won't do as I lost the driver.... I had a chance to borrow a good encoder so doing some tests before I return it. If I'm going to know more after these tests or not I can't say but it was fun so far

and different from most of my experiments it did not cost anything so fun for free :)... if anyone gets any knowledge from this - awesome, if not, it will be another useless thread on the forum ppl can ignore

and different from most of my experiments it did not cost anything so fun for free :)... if anyone gets any knowledge from this - awesome, if not, it will be another useless thread on the forum ppl can ignoreAs to a closed loop system how much would you have to spend to get a system of interest to you?

Well I have experience with servo's and they are as precise as the encoder. The servos that use the encoder I borrowed move some very nasty stuff that kills ppl 5+ km away so precision is not a joke there. With steppers I assume the same could be achieved so I expected the closed loop stepper I have with real encoder to behave like servo (only slower) and wanted to just "prove that" to myself, while I had some reservations about "magnetic encoder" used on the S42B so wanted to test that and I think I got the info I expected - precision of S42B is terrible... Good encoder is expensive, the 16bit one go over 1000eur easily so it really depends on the precision you want

The setup I got was just for fun, from STEPPERONLINE, and it was only $100 so if it turns out to be crap I will not be surprised or upset. I wasn't prepared to spend a lot for just having some fun.

I wanted to test

https://www.vallder-rs.com/en/c/426/38/stepper-motor-drivers/servo-stepper-2-2-nm-detailit's rather cheap (90eur + 20% VAT) bulgarian clone of the PRC leadshine device. From what I'm told they use identical software and identical encoder as more powerful

https://www.vallder-rs.com/en/c/292/38/stepper-motor-drivers/closed-loop-stepper-8-5nm-detail

and

https://www.vallder-rs.com/en/c/688/38/stepper-motor-drivers/servo-stepper-12-5-nm-detail

difference is in motor size and output fet's on the driver so testing a smallest one should give all the data required... only they have zero on stock attm and my driver is somewhere in this chaos in my room so I might find it (I found the motor

so I might find it (I found the motor  ) but...

) but...For the 3D printing, I'm not sure any of the Vallder devices work as smallest motors are nema23, they are rather heavy and with lot of rotor inertia, the price is not a big deal but weight might be. On the other hand clearpath, alphastep and others maybe have nema17 in the offer too.. but I don't have them in offer locally

-

@arhi said in stepper precision:

I wanted to test

https://www.vallder-rs.com/en/c/426/38/stepper-motor-drivers/servo-stepper-2-2-nm-detailThanks VERY much for all that feedback.

For comparison this is the setup I got:

Frederick

-

Just in case someone on this thread missed the link from the original thread (linked at the very top of this thread), here is a paper I wrote on the topic of measuring stepper errors and encoder errors.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4911639/

It may be of significant interest. This link is to the non-paywalled pubmedcentral source. The original (paywalled) article is in Metrologia (the official journal of the Bureau Internationale des Poids et Mesures, which oversees the metric system worldwide).

Also, here is a second paper, which discusses periodic errors in interpolated encoders. However, I don't think any of the discussions above refer to encoders that interpolate between their reference marks. The long, ugly token at the end of the link de-paywalls it. (Note that this is legal; it is an official U.S. Gov't publication, and free of copyright, at least in the USA). (Changed link... de-paywalling wasn't really working). It seems that the PDF link on Google Scholar may de-paywall this correctly. Try this:

and use the PDF link

-

@fcwilt said in stepper precision:

For comparison this is the setup I got:

Looks like another leadshine clone