Tired of Mod, tweak, tune, repair, rinse, repeat...

-

Very neat! I'd be interested in seeing a list of all the things you 'fortified' or considered and made adjustments to in order to get the rigidity you now like.

A much easier request though - which 5020 fan are you using?

-

-

@macguyver that machine is awesome but i think you underestimated the weight of the moving gantry. Looking at the prints there are a lot of problems caused by too much speed/acceleration value. Considering that a normal core xy is printing at 150mm/s without that it would be a limitation for that build size. However, also at lower speed, i'm sure that this machine is going to be a really reliable workhorse! Keep up the great work.

-

@macguyver

Do you have any problems with heat-expansion on your gantry?

I've just heated up my chamber to 50C and noticed the gantry moved much easier by hand, than I was used to.

I've fixed the crossbeam of my gantry only on one side and let the other side float in one direction because I was afraid of heat-expansion when I built it. But still it runs tighter, when cold.

IMHO, the belts are now your weakest link. My philosophy " Sturdy frame, but lightweight gantry" -

@o_lampe As the frame expands, the pulleys and motors move father apart, increasing tension on the belts (assuming the belts don't expand much when warmed). That may be what causes the increased effort to move the mechanism when it's warm.

I keep one end of the X axis fixed on the Y axis pulley block and the other end is mounted using a second bearing block on the X axis rail. That allows the Y axis rails and pulley blocks to move apart as the mechanism heats up while preventing motion in any direction but X.

I've never paid attention to the force required to move the mechanism over temperature changes. It works fine at all temperatures.

-

@lael said in Tired of Mod, tweak, tune, repair, rinse, repeat...:

Very neat! I'd be interested in seeing a list of all the things you 'fortified' or considered and made adjustments to in order to get the rigidity you now like.

A much easier request though - which 5020 fan are you using?

There are 2 main sources of flex in most frames. The attachment points, and the frame material itself. Gussets and brackets tend to be a bandaid for both of these.

The main goal was to get away from gussets, brackets, and the slop of extrusions for the motion system. The second goal was to make the frame and everything that attaches to it as constrained as possible. Parts like the Z upright, Z steppper/ballscrew mount, and even the belt idlers are aligned and kept rigid and aligned with pins through reamed holes and the entire frame is assembled with M8 bolts.

That makes all the attachment points solid. From there the weak link would be the material of the frame itself, and that's easily solved with bulk. A 4mm plate may flex, if an 18mm plate does, you have bigger problems.

As for the fan. Amazon sent me this one by mistake, and I'm glad they did.

adda ab05012ub200b00 I had ordered a adda ab05012dx200600. The second one they sent me was correct, and does not compare in performance. -

@o_lampe said in Tired of Mod, tweak, tune, repair, rinse, repeat...:

@macguyver

Do you have any problems with heat-expansion on your gantry?

I've just heated up my chamber to 50C and noticed the gantry moved much easier by hand, than I was used to.

I've fixed the crossbeam of my gantry only on one side and let the other side float in one direction because I was afraid of heat-expansion when I built it. But still it runs tighter, when cold.

IMHO, the belts are now your weakest link. My philosophy " Sturdy frame, but lightweight gantry"no problems with expansion. I used Mic6 for the whole motion system though, so any expansion should happen fairly evenly without any warping.

And yes, belts are weakest link. Next one gets 10-12mm, or rapid traverse ballscrews...

-

@mrehorstdmd said in Tired of Mod, tweak, tune, repair, rinse, repeat...:

I keep one end of the X axis fixed on the Y axis pulley block and the other end is mounted using a second bearing block on the X axis rail.

That's quite elegant!

@macguyver said in Tired of Mod, tweak, tune, repair, rinse, repeat...:

There are 2 main sources of flex in most frames. The attachment points, and the frame material itself.

Right, but there is another thing: moving mass

Keep it low, and the frame can be much lighter with the same result. Or in your case, print much faster with less ringing. -

@o_lampe It turns out that it wasn't a ringing issue. It was the acceleration on the Z axis iirc. I solved that a while ago. I'm now printing at 350mm/s all day long. I have the firmware set to 6000 acceleration for x&y.

-

Nice machine! Makes me want to start planning my next build.

-

Yeah, I've been planning the next one for a while now. So far the changes on the next one are.

-

12mm belts or I might go real crazy with rapid traverse ball screws...

-

Bigger steppers, have to do some research to see if they're worth it.

-

A modified E3d tool changer. Going to try to make it double sided. 8-10 tools.

-

PEI coat the bed. The Germans call it Dauerdruckplatte. I'll probably see if i can find a local plating company that can do it.

-

And a part of me wants to make a robotic arm, though I doubt I'd actually ever use it. That's never stopped me from doing stupid things in the past though...

-

-

Great work!

@macguyver said in Tired of Mod, tweak, tune, repair, rinse, repeat...:

...with plenty of din rails

I always forget about DIN rails, maybe because they're not so common in the US. If I re-arrange Black Beauty's guts, I'll have to remember.

@macguyver said in Tired of Mod, tweak, tune, repair, rinse, repeat...:

I've moved over to Prusaslicer from Simplify3d.

Same here. Simplify3D was just getting on my nerves.

-

Made some good changes this weekend! Finally had a few days to myself with no distractions and took the time to learn node red. So now I have a couple more safety features in there. I have temperature monitors that should turn off the printer if it goes over or under certain temperatures. More importantly I have telegram notifications running directly from the raspberry pi, no more open browser needed!! Thanks @MintyTrebor 's for his nodered plugins for that! All I got left to do is get the webcam screenshot figured out and set up a few telegram commands so I can do things remotely.

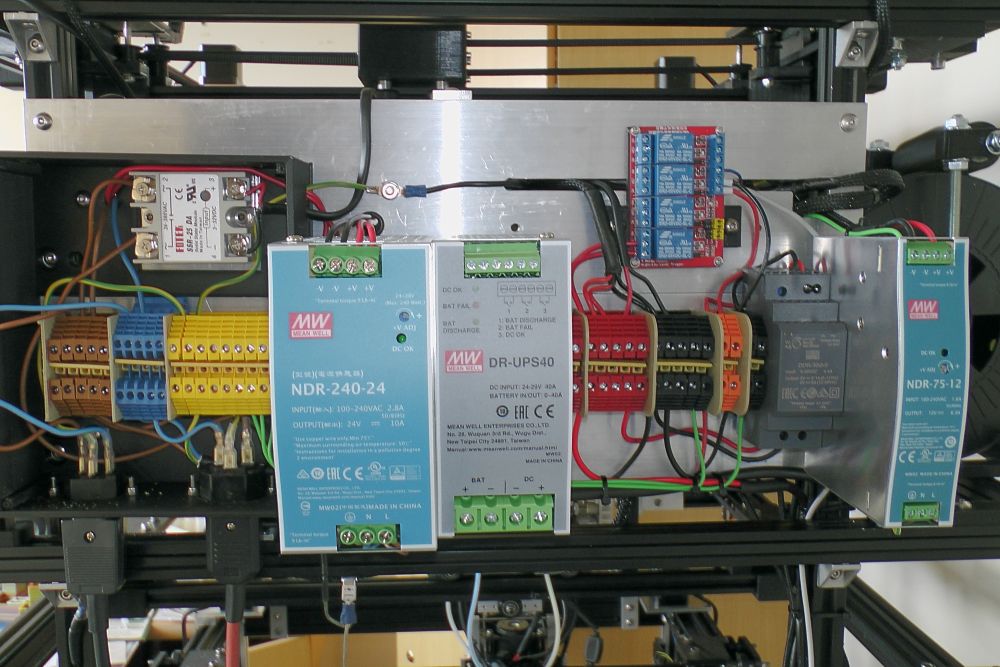

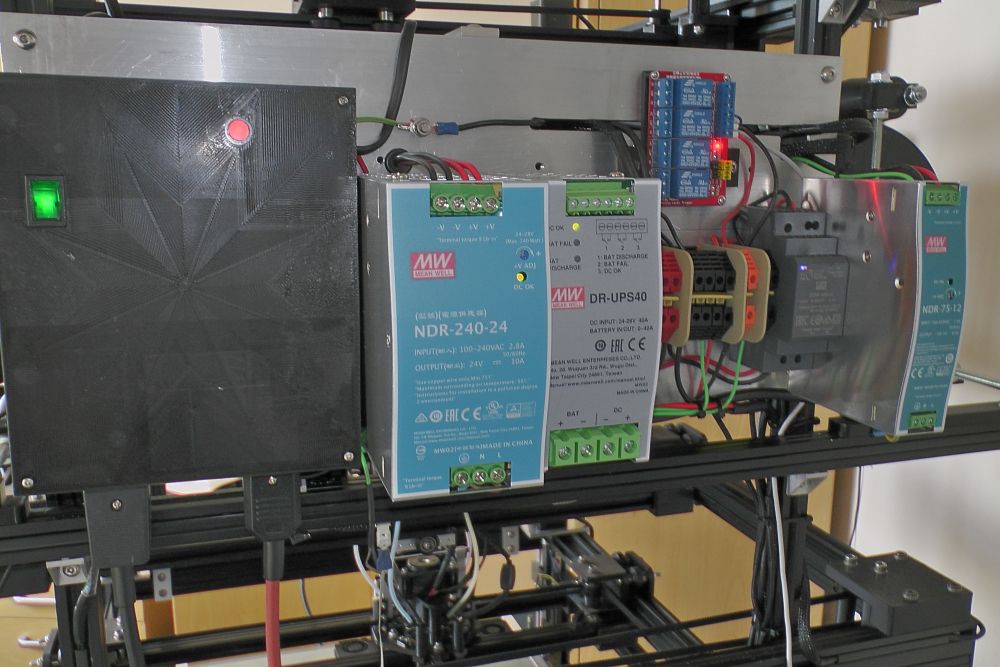

Then I did some upgrades and modifications in my electrical drawer. New top o the line Pi, WITH rgb heatsink, of course, and a breakout board to access the unused gpio's neatly. New 12&24v power supplies. And I tidied up the wiring, a little.

![PXL_20211226_022656764[1].jpg](/assets/uploads/files/1640487553373-pxl_20211226_022656764-1-resized.jpg)