DUET 3 6HC - Using Inductive proximity sensor as endstop

-

Hello everyone,

I am currently developping a 5Axis manufacturing plateform in which I would like to use Inductive proximity sensors as endstop, here is a photo of the machine in it's current state.

The model that i would like to implement is a SN-04 NPN like this one

I wanted to know what would be the best way to connect those endstop to the Duet 3 and how should i implement the firmware part.

For the moment I wanted to power the sensor with a 12V signal comming from a always on fan pin and use the I0_0_IN pin of the GPIO as the sensor input.

What do you think ?

Tom

-

Using such a device as an endstop is fine.

I tested a number of different inductive sensors and the one thing that all had in common was the needed to use something to get the logic voltage levels from the sensor to be compatible with the logic voltage levels needed by the Duet.

I found that two resistors of suitable values in a suitable arrangement could obtain the needed levels - but different sensors needed different values/arrangements.

Frederick

-

I believe the inputs are tolerant up to 30v so just plug it in and go.

I use a very similar one on the mini5+ at 24v with no modifications or extra resistors etc -

@jay_s_uk said in DUET 3 6HC - Using Inductive proximity sensor as endstop:

I believe the inputs are tolerant up to 30v so just plug it in and go.

I use a very similar one on the mini5+ at 24v with no modifications or extra resistors etcTrue the inputs will not be harmed but you still have to insure the logic levels are correct.

The output levels of the sensors I tested were all over the place.

Frederick

-

Would there be any interest in Duet3D manufacturing and selling a small inductive sensor that runs from 3.3V or 5V? Most of the existing sensors advertised as being 5V appears to be 6 to 36V sensors sold as 5V.

-

definitely!

-

@dc42 yes definitely

-

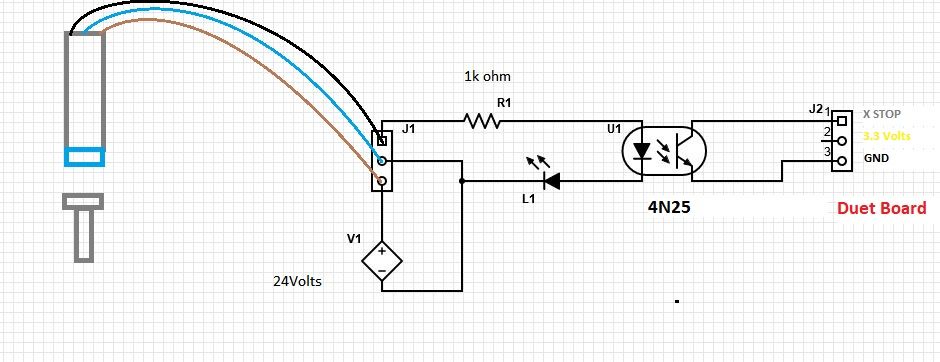

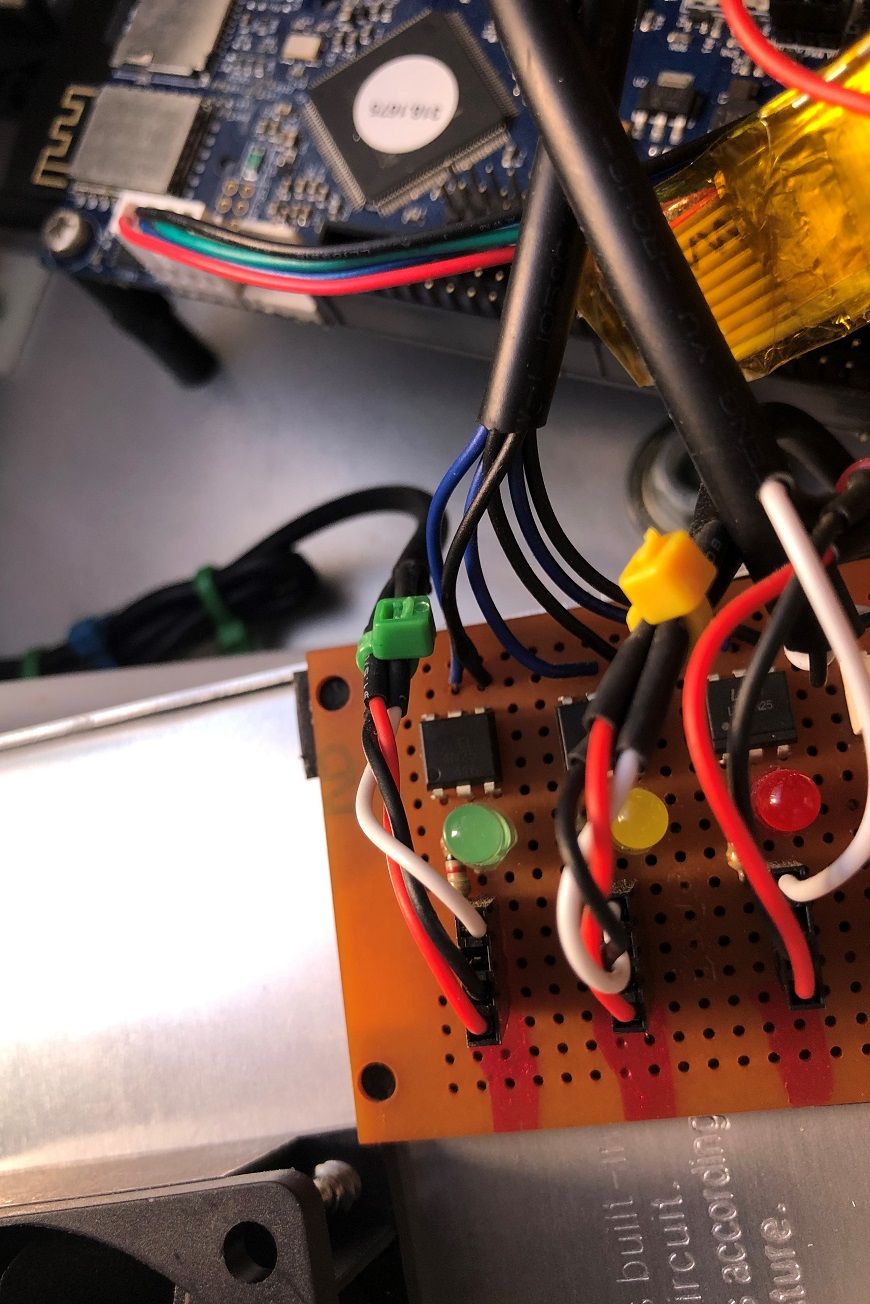

opto isolator x 4 on my Delta , allows you to use what ever voltage the sensor works best with ( in my case 24volts) , isolates the high voltage from the low , decouples any kind of line noise from steppers etc and doesn't toast the board if you plug it in backwards

in config file use

M574 X2 S1 P"!xstop" ; configure active low endstop for high end on X via pin xstop !prefix

-

@DigiD using optocoupler is a great idea and using a LED for added signal is it also!

-

Clever.

What is the brand and part number of the inductive sensor you are using?

I will have to re-test the sensors I tested to see if they would work with such a circuit.

Frederick

-

@dc42 said in DUET 3 6HC - Using Inductive proximity sensor as endstop:

Would there be any interest in Duet3D manufacturing and selling a small inductive sensor that runs from 3.3V or 5V?

Yes if it could be as small as the 8mm cylindrical inductive sensor I use now.

And the switching frequency should be 2 kHz or better.

Most of the existing sensors advertised as being 5V appears to be 6 to 36V sensors sold as 5V.

Perhaps that is why the two models I tested didn't work as well as those rated 10-30 volts.

Frederick

-

@fcwilt said in DUET 3 6HC - Using Inductive proximity sensor as endstop:

Yes if it could be as small as the 8mm cylindrical inductive sensor I use now.

We're looking at using a 6mm diameter sense coil. We would supply the PCB and the sense coil, leaving you to print an enclosure for it (we would publish a sample design). It would be designed to work well with non-magnetic surfaces, but would work with magnetic surfaces too. We would aim for 1ms response time.

-

@dc42 said in DUET 3 6HC - Using Inductive proximity sensor as endstop:

We're looking at using a 6mm diameter sense coil. We would supply the PCB and the sense coil, leaving you to print an enclosure for it (we would publish a sample design). It would be designed to work well with non-magnetic surfaces, but would work with magnetic surfaces too. We would aim for 1ms response time.

That all sounds reasonable.

Send me a couple and I will test them and add them to my list.

Frederick

-

LJ12A3-4-Z/BX Inductive Proximity sensor NPN (OMRON and no name brands seem to work equally well) , very common on Ebay about $3-4 AUD each

4mm sensing distance , best results using mild steel as a target that is close to the diameter of the sensor . derate sense distance for stainless .7 and Aluminium .4

been in the printer for a few years now with out any issues

I use first pass fast coarse and second pass slower accurate for homing

-

@dc42 I would definitely be interesting in something like that!

-

@DigiD said in [DUET 3 6HC - Using Inductive proximity sensor as endstop]> LJ12A3-4-Z/BX Inductive Proximity sensor NPN (OMRON and no name brands seem to work equally well) , very common on Ebay about $3-4 AUD each

Interesting.

The number looked familiar.

I had ordered one of each variety (-AX -AY -BX -BY -BX-5V) under the TWIDEC brand but they do not appear in my list of tested devices.

I need to find them and finish testing.

Frederick

-

@DigiD Thank you for your help, how should I select the OptoCoupler and the resistor based on the model of inductive endstop that I used ?

-

Hello Thank you for your help,

How do I test that the logic levels are correct and how should I correct if they are not ?

Thank you,

Tom -

@reFlexlab said in DUET 3 6HC - Using Inductive proximity sensor as endstop:

Hello Thank you for your help,

How do I test that the logic levels are correct and how should I correct if they are not ?

Thank you,

TomI have an oscilloscope that I use but any device capable of measuring DC voltages in the 0 to 24 volt range would work.

Here is an example of the small low cost oscilloscopes available today. This one is half the cost of the older unit I have and five times as fast.

The OptoCoupler used is a 4N25 which is quite common.

The 1K resistor should be good for most inductive sensors IF they source current which is usually the case for PNP types of sensors.

NPN types of sensors usually sink current in which case the cathode end of L1 would connect to the sensor output and the J1 end of the resistor would connect to power source, labeled V1+ in the diagram above.

Yet I have found PNP and NPN types that both source and sink current.

I wish manufactures would stick to pure open-emitter (PNP) or open-collector (NPN) designs. Sigh...

You can start with just R1 and L1 connected to sensor output and ground OR sensor power and output. If L1 goes on and off with the sensor then you have found the correct setup and can finish the wiring adding the 4N25, etc.

Frederick