DWC 3.1.1

-

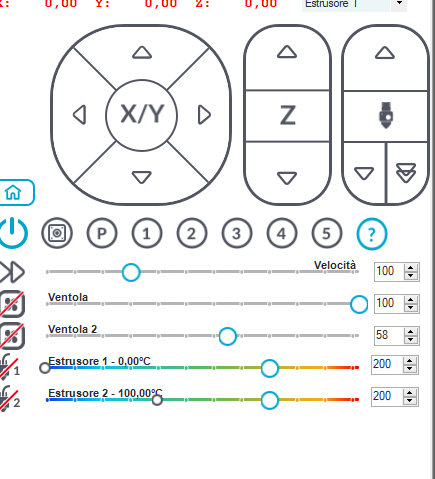

ORA OK , MANCA IL SECONDO RISCALDATORE , SONO NOMINITA 0 E 1 ANCHE REPETIER LI NOMINA COSI' E NON SETE LA TEMPERATURA DEL PRIMO RISCALDATORE . HO RISOLTO GRAZIE A TE LA VERSIONE TE NE SONO GRATO MA NON CAPISCO PERCHE' FUNZIONA SOLO CON JAVA.

1 IL PRIMO RISCALDATORE ASSENE

2 PERCHE' JAVA ? -

-

-

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4388 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M308 S2 P"e1temp" Y"thermistor" T100000 B4388 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 2 to 280C -

Post the full contents of your config.g

Java is required for it to work. That's just the way it's made.

-

SCUSA AMICO , NON HO CAPITO COSA DEVO FARE

-

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.2.2 on Wed Jan 20 2021 16:02:24 GMT+0100 (Ora standard dell’Europa centrale); General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"TATONA" ; set printer name

M665 R165.29 L334 B130 H501.5 ; Set delta radius, diagonal rod length, printable radius and homed height

M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them; Network

M540 PBE:EF:DE:AD:FE:ED ; set custom MAC address

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z80.00 E663.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z1200.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X18000.00 Y18000.00 Z18000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z1000.00 E1000.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z-0.1 S1 ; set minimum Z; Endstops

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop; Z-Probe

M950 S0 C"exp.heater7" ; create servo pin 0 for BLTouch

M558 P9 C"^zprobe.in" H10 F120 T2400 ; set Z probe type to bltouch and the dive height + speeds

M558 H30 ;*** Remove this line after delta calibration has been done and new delta parameters have been saved

G31 P500 X11 Y0 Z2 ; set Z probe trigger value, offset and trigger height

M557 R130 S20 ; define mesh grid; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4388 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M308 S2 P"e1temp" Y"thermistor" T100000 B4388 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 2 to 280C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off; Tools

M563 P1 S"1" D0 H1 F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings

m501; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory -

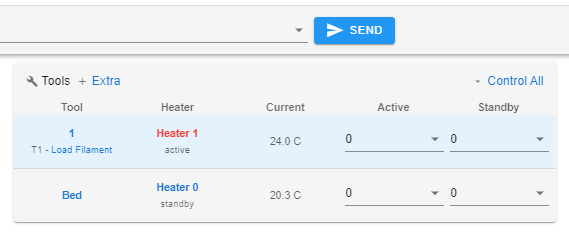

@luca-Massimiliano said in DWC 3.1.1:

; Tools

M563 P1 S"1" D0 H1 F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0CYou only have one tool defined, so only one tool will show in the web interface.

You have the heater configured, but it needs to be associated with a tool to be controlled.

-

GRAZIE VERAMENTE PRECISO E PREPARATISSIMO FUNZIONA , (NON HO PROVATO L ESTRUSIONE PER ORA)

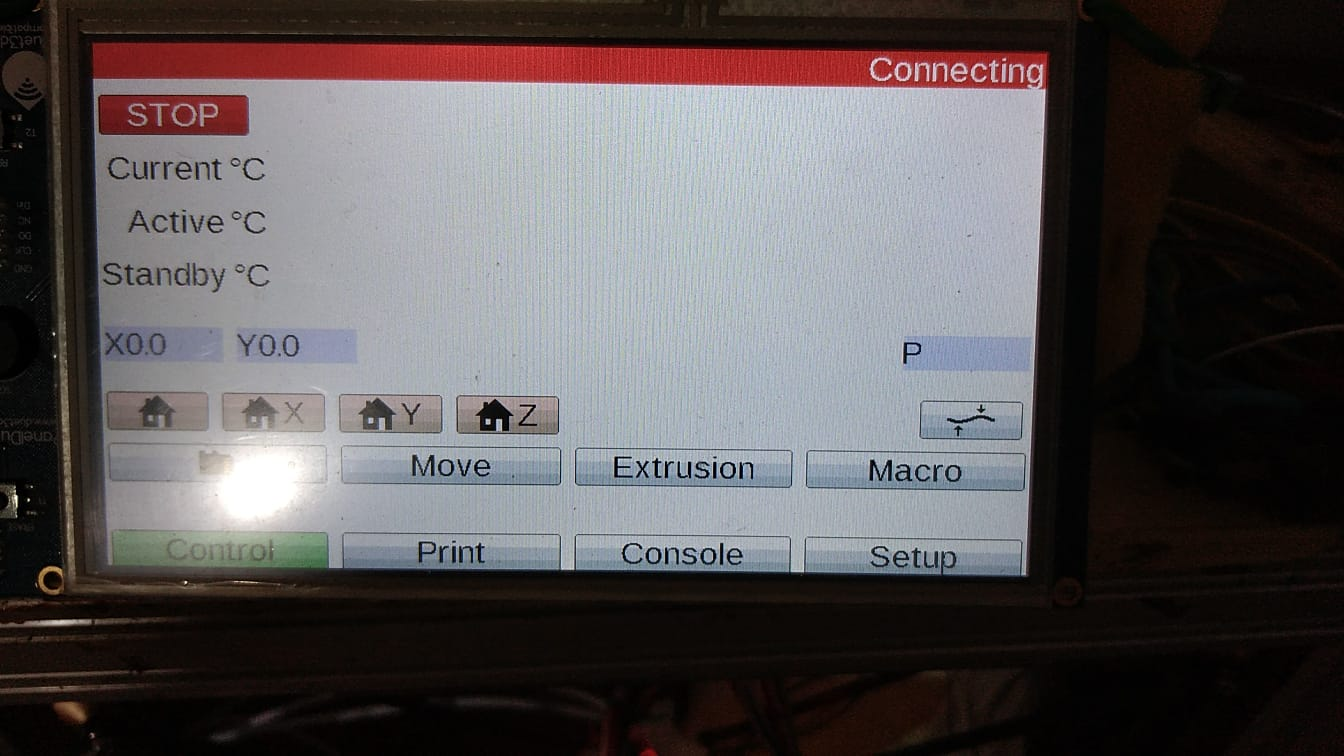

HO UN PROBLEMA INVECIE PanelDue Firmware. CON QUALE Firmware DIVENTA COMPATIBILE?

-

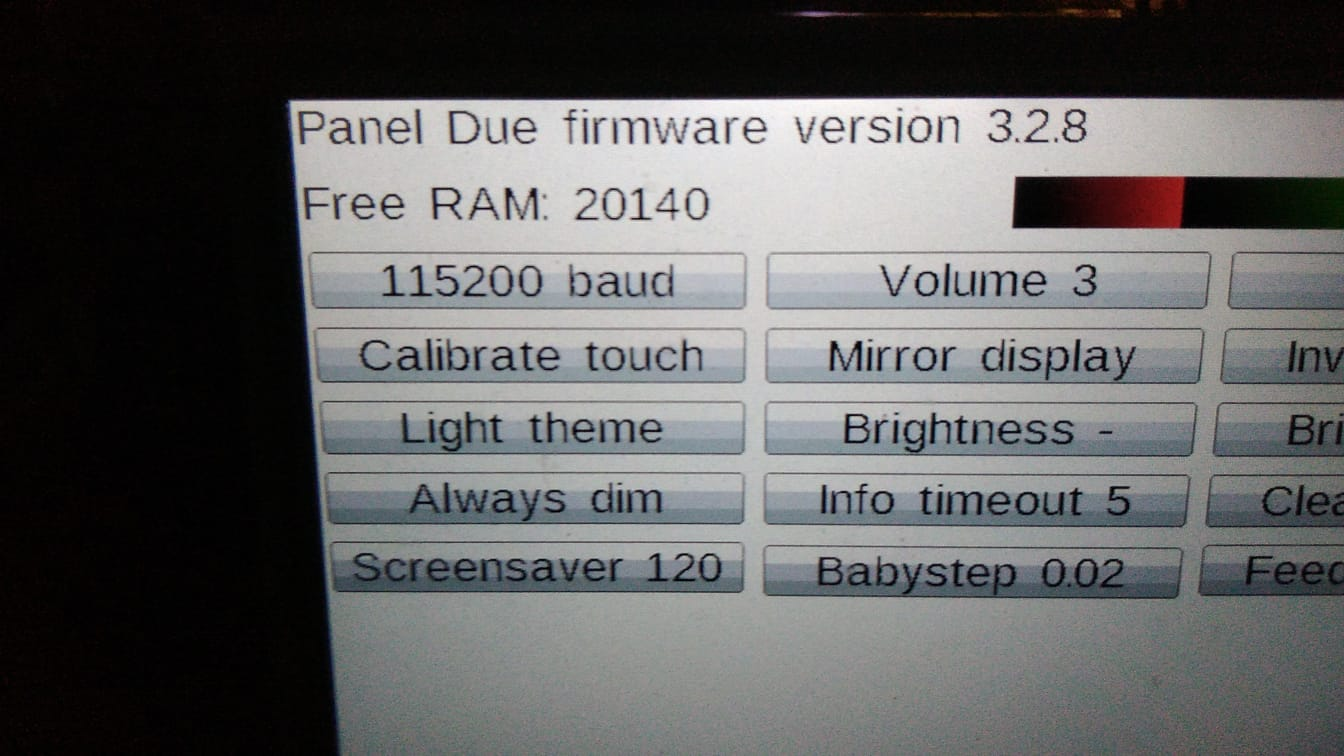

What version of firmware is on the PanelDue? Check in the Setup page on the Panel.

It should be at least 1.24

https://duet3d.dozuki.com/Wiki/PanelDue_Firmware_update

What baud rate is it set to? It should be 57600 to match what you have set in config.g

-

3.28

-

Your baud rate doesn't match. In PanelDue it shows 115200 baud. Press that button until it shows 57600.

-

GRANDIOSO I BAUD GRAZIE MILLE . SONO A BUON PUNTO DIREI COME POSSO RICAMBIARE IL TUO ENORME AIUTO

-

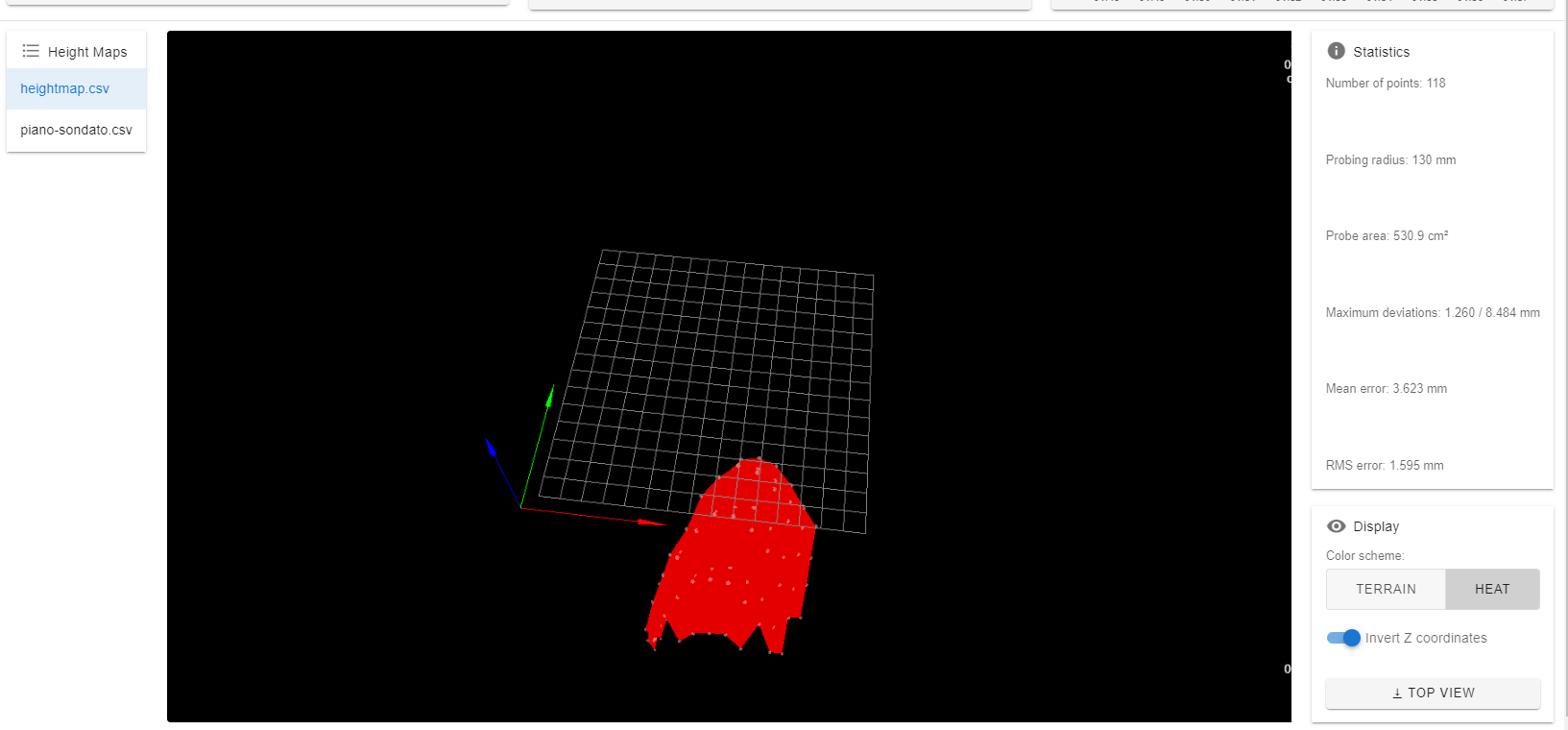

NON HO FATTO CON A NUOVA CONFIGURAZIONE SONDAGGIO AUTOMATICO . IO HO UNA DELTA KOSSEL CIRCOLARE E RIPORTA I VALORI APPROSIMATICI E NORMALE CHE USI UNA BASE QUADRATA? SCUSA NON VORREI AVER DIMETICATO DELLE CONFIGURAZIONI.

-

-

CIAO

non ho mai capito una cosa :

perche' se MODIFICO IL VALORE NEL CONFIG .G DI H506.5 NON CAMBIA MAI E DEVO CAMBIARLO SU RepRapFirmware Configuration Tool ?

M665 R165.29 L334 B130 H506.5 ; Set delta radius, diagonal rod length, printable radius and homed height -

I think that would be handled with delta calibration. I'm not very savvy with deltas, but those two links to configure and calibrate should get you going.

-

SI HAI RAGIONE POSSO CAMBIARLO SOLO CON Configuration Tool MA LO CALCOLCO PRIMA MEDIANTE I SOLITI SISEMI , MA SOLO Configuration Tool RIESCE A SALVARE IL VALORE ,IL CHE RENDE TUTTO MOLTO PIU' LABORIOSO, GRAZIE

-

Just edit the config.g file in the web interface. It's in the system tab. You do not need to go back to the configuration tool every time.

-

I DO NOT UNDERSTAND n the web interface.