Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning

-

@zapta said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

The Adafruit LIS3DH is available in my country on Amazon, $7 Prime shipped.

https://www.amazon.com/Adafruit-LIS3DH-Triple-Axis-Accelerometer-ADA2809/dp/B01BU70B64

@dc42, will input shaping be supported on stand alone Duet2 Wifi?

Yes, but perhaps not on the Duet Maestro because it doesn't have floating point hardware.

-

@dc42 no problem at all at buying another accelerometer, but just for reference, amazon IT has ADXL345 at €5.99 with prime, LIS3DH €15.46 with prime. Most important is: are there differences on precision of the readings between these 2? 10€ difference is not a problem compared to accuracy of readings

-

I am looking forward to this feature set...

-

-

@dc42 said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

sample results at https://forum.e3d-online.com/threads/accelerometer-and-resonance-measurements-of-the-motion-system.3445/#post-38177.

@dc42, Can you post the graphs here? E3D requires registration to view them.

-

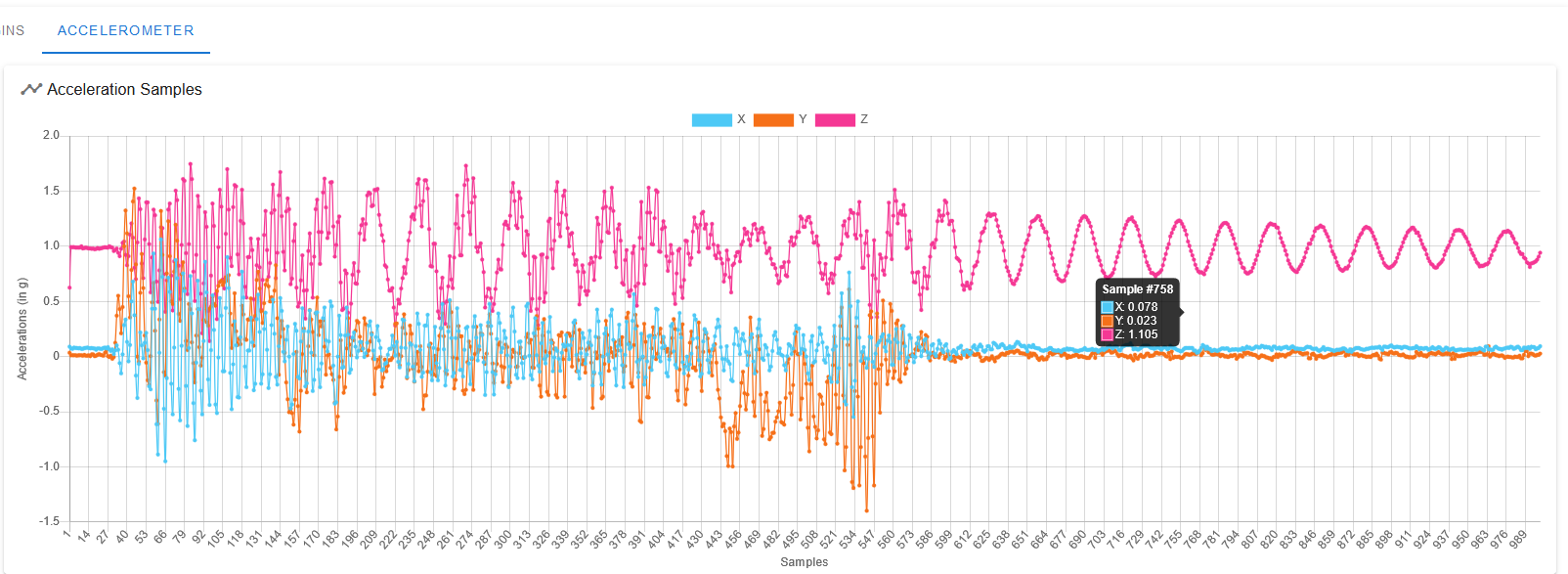

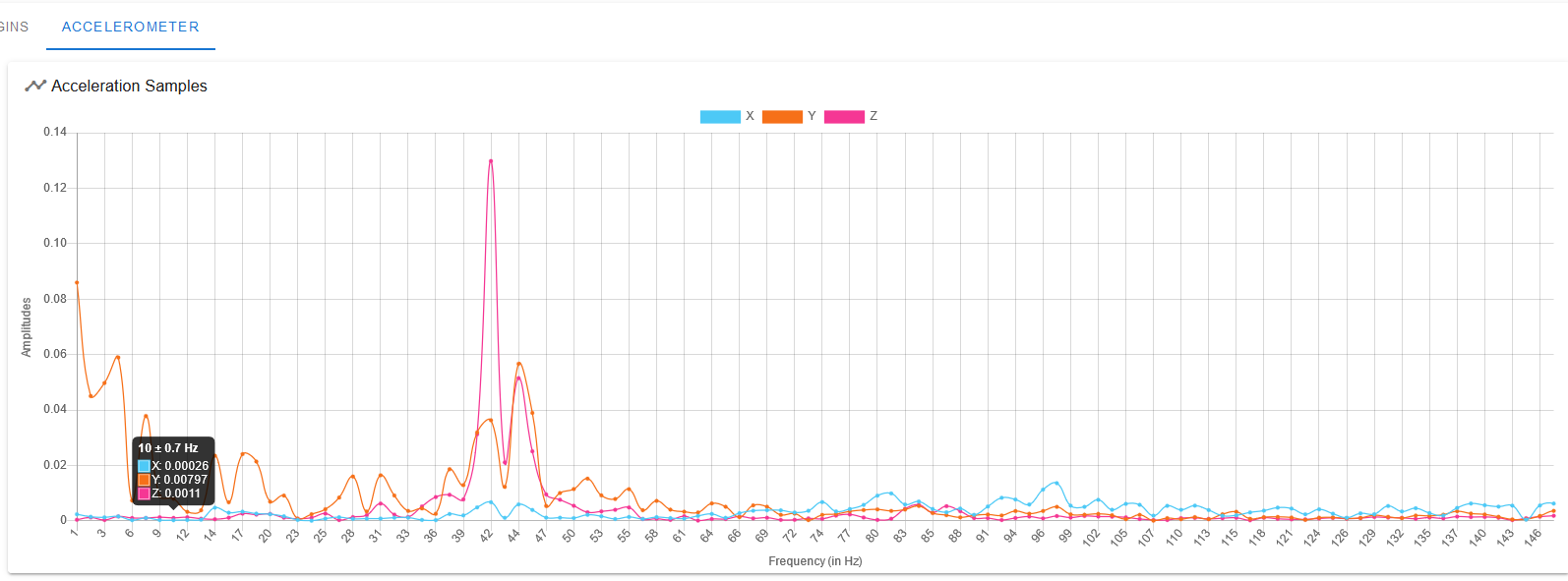

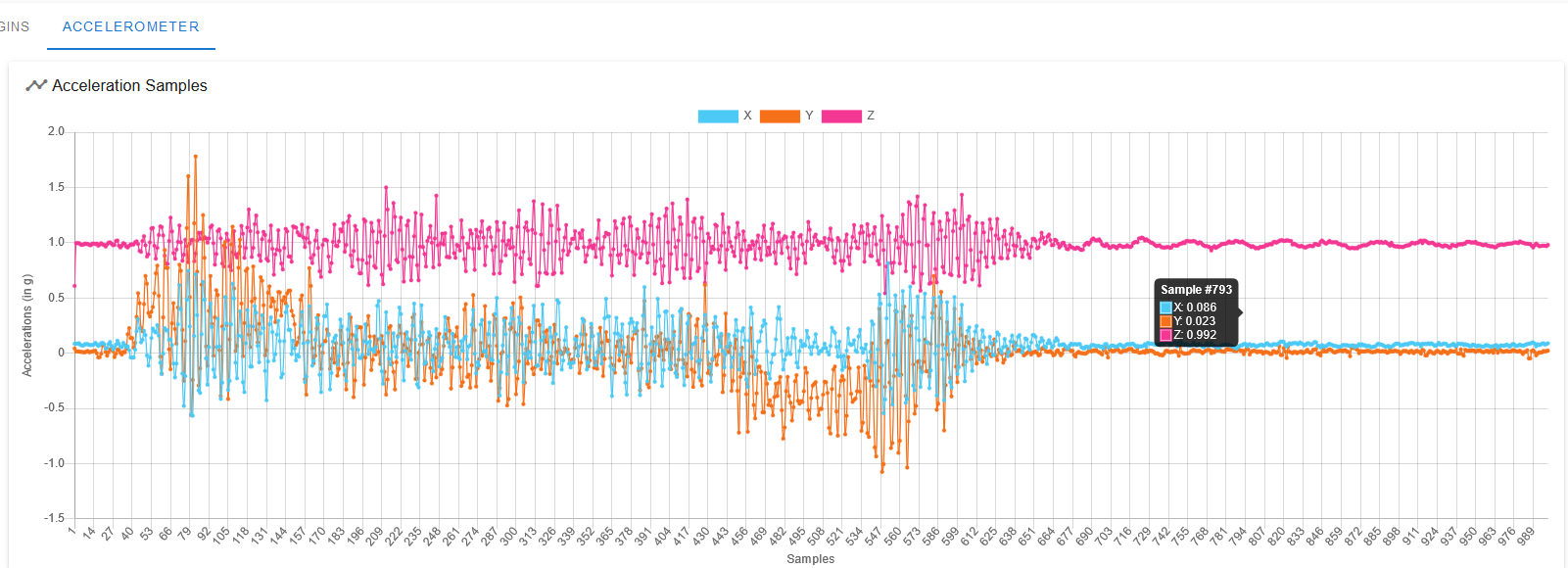

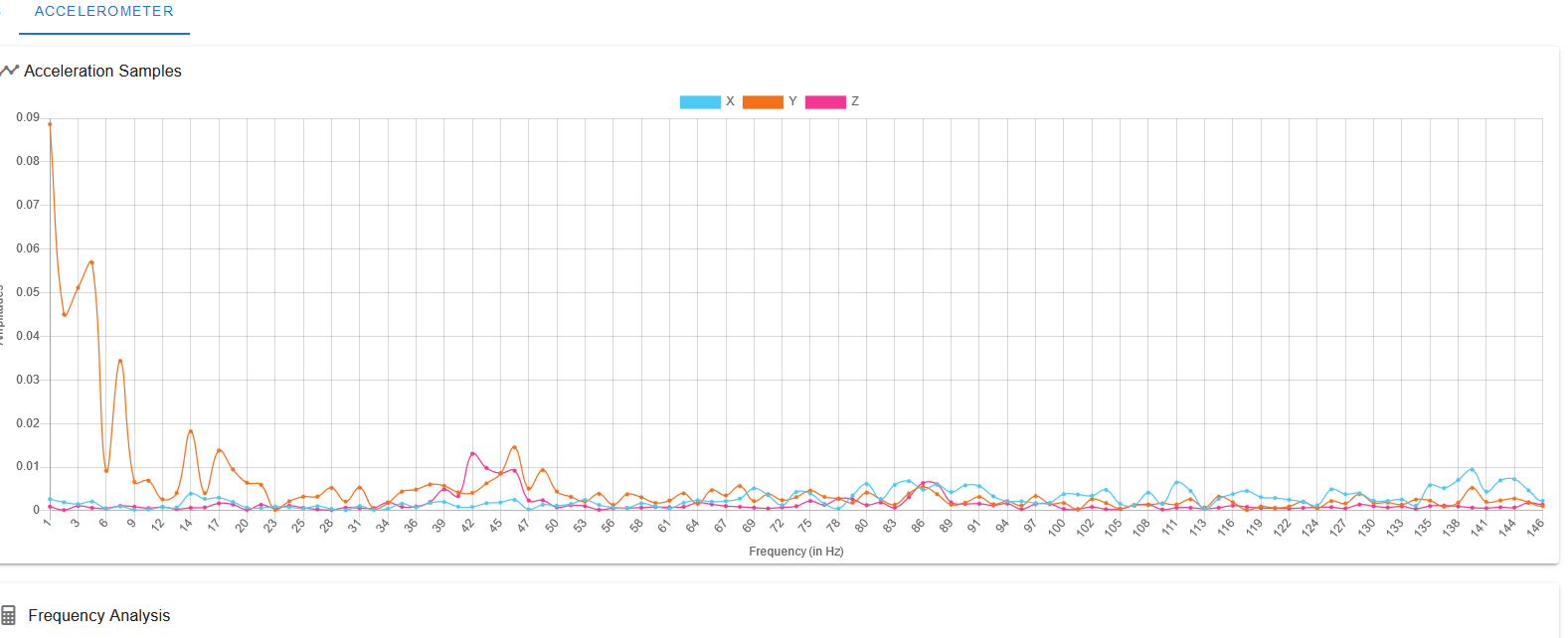

The first two are without input shaping. The second two are with ZVD input shaping at 42Hz. ZVDD didn't give any further improvement, and both EI2 and EI3 were worse.

-

Very nice seeing progress there!

Also as usual it looks very tidy and well thought out so far.just ordered a Adafruit LIS3DH and plan to experiment with the new feature.

I see (experimental?) input shapers are also already implemented in the 3.3-input-shaper branch.Is it already worth to try and experiment with the feature also during printing conditions?

Would like to see how the input shapers work with a typical i3 bed slinger as these printers tend to have different ringing frequencies at once. And I also could provide some results/data. -

@argo said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

I see (experimental?) input shapers are also already implemented in the 3.3-input-shaper branch.

Is it already worth to try and experiment with the feature also during printing conditions?Experiment if you like; but the code is by no means complete, so be very careful. Pressure advance is disabled - I haven't even tried extruding. Delta kinematics is not implemented.

Input shaping will only work on moves for which the acceleration time is long enough to apply it, i.e. at least 2 * the shaping time. So you may need to reduce acceleration to get it applied. I believe there is some scope to apply it to shorter acceleration times, down to 1 * the shaping time + one half period, at least when using ZVD or ZVDD, but that isn't implemented yet. Also I will probably implement reducing acceleration (but not below a minimum) where necessary to allow input shaping to be applied.

I don't expect to include the input shaping code in the 3.3 release.

-

Hi All,

Can anyone recommend a link to a good article on what input shaping is and what print features it addresses? I'm assuming it's about removing excitation of the printers structural modes from the demand, but I guess there are more subtle nuances too.Edit: I assume this is the accelerometer mentioned.

https://www.ebay.co.uk/itm/232427148679

Many thanks

Barry M -

Yes that's the sensor.

Input shaper ZVD(D) paper:

https://www.researchgate.net/publication/316556412_INPUT_SHAPING_CONTROL_TO_REDUCE_RESIDUAL_VIBRATION_OF_A_FLEXIBLE_BEAMEI2 input shaper:

http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.465.1337&rep=rep1&type=pdfMost simple explanation: It basically cancels out ringing frequencies.

@dc42

Defining a minimum and maximum acceleration range might be good approach for input shaping.

With Klipper's (automatic) calibration measurement you can set a "max smoothing target" as too much acceleration may lead to losing fine details. It then recommends to stay below a specific acceleration, depending on the used shaper the value differs.

What Klipper does not offer though is to set a specific acceleration range. Meaning, if printing small details, the acceleration slows down as needed, so the shaper works properly.Speaking of pressure advance. Is some sort of pressure advance smoothing planned?

-

I have just order two of these https://shop.pimoroni.com/products/adafruit-lis3dh-triple-axis-accelerometer-2g-4g-8g-16g in anticipation.

Doug

-

Here are some other relevant UK listings:

https://www.hobbytronics.co.uk//index.php?route=product/search&search=lis3dh

https://thepihut.com/products/adafruit-lis3dh-triple-axis-accelerometer-2g-4g-8g-16gAccelerometer support (but not input shaping) will be available in release 3.3beta3.

-

@dc42 thanks for the updates! Will wait for 3.4 and accelerometer receive to test that!

-

So exciting....this is a wonderful addition to the ecosystem.

Thank you! -

@dc42 My accelerometer is in the mail. When will 3.3 beta 3 be released?

-

@generisi said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

@dc42 My accelerometer is in the mail. When will 3.3 beta 3 be released?

As soon as I have a fix for the issue of spurious VIN undervoltage reports on Duet 3 Mini with attached SBC. If your accelerometer arrives before then, there is a preview available at https://www.dropbox.com/sh/b65da04w1gl94nf/AACLpPslfDiWDlJN5KDdPydAa?dl=0.

-

I assume this works for a Cartesian style machine.

I'd mainly be looking to address the "springyness" in my polar bed due to the large drive belt and bed inertia. At the moment I keep the acceleration and max rotation speed fairly low, but I'm updating the bed drive to closed loop so I can push it harder.

Is this something that'll help, and if so will I be able to use the accelerometer on the rotating bed to identify the relevant frequencies?

Just looking to understand how it'll integrate with the polar printer.

I'm guessing that once I've converted my Wanhao D4S to my recently purchased Duet3 mini card this'll all be directly relevant.

Just one final thought, if I have several different mass tool heads will I be able to assign different frequencies for each of them?

Really interesting stuff folks!

All the best

Barry M -

@cncmodeller said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

I assume this works for a Cartesian style machine.

If you mean the input shaping, then yes, although so far I have only tested motion on a CoreXY machine, and not tested extrusion. The accelerometer support should work with any kinematics.

Is this something that'll help, and if so will I be able to use the accelerometer on the rotating bed to identify the relevant frequencies?

Possibly, depending on the nature of the drive between the motor and the bed.

I'm guessing that once I've converted my Wanhao D4S to my recently purchased Duet3 mini card this'll all be directly relevant.

Duet 3 Mini is a good choice, because it has enough spare RAM and flash memory to take further than we can take the Duet 2 WiFi/Ethernet.

Just one final thought, if I have several different mass tool heads will I be able to assign different frequencies for each of them?

Yes, by including M593 commands in your tool change files.

-

@dc42 said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

@cncmodeller said in Input Shapers: 2HUMP_EI & 3HUMP_EI + Auto Tuning:

Possibly, depending on the nature of the drive between the motor and the bed.

Hi @dc42

The polar bed drive arrangement can be seen in the linked video.

https://youtu.be/I-7yMkPdsTQ?t=121

I'm now back to direct drive without a gearbox and A much bigger stepper.

The bed pulley is a custom laser cut 720 tooth gt2 profile with a 1100 tooth (ish) belt to the 20 tooth pulley on the stepper motor.

Pulley construction:

https://youtu.be/KNGRAxSSkAQ -

@dc42 Thank you!