To print in two colors with direct drive & Duet2WiFi

-

Good mornig, I wolud like to improve my CoreXY printer based on a Duet2WiFi to make it capable of print in 2 colors (or 2 materials thinking about soluble filament for supports). I'm not interested to print more than 2 for various reasons. The only thing I absolutelt want is to keep a "direct drive philosophy", I don't want to go back to bowden never never more...has someone some "hardware" hints about how to make it? For me it would be better to have a single nozzle because I think there will be too much problem for allining two nozzles....how about it, am I asking too much?

Thanks and regards!

Andreap.s.

Mosaic Palette is too much expensive and, as I said, I'm not interested to print in 4 or more colors.... -

@the_dragonlord Have a look at the Dondolo and derivated: https://www.thingiverse.com/search?q=dondolo&type=things&sort=relevant

-

@fma said in To print in two colors with direct drive & Duet2WiFi:

@the_dragonlord Have a look at the Dondolo and derivated: https://www.thingiverse.com/search?q=dondolo&type=things&sort=relevant

Thank you very much but I don't want to mess with a dual nozzle system...too many troubles to solve for the allingment.....but this project is great indeed!

-

@the_dragonlord I agree, aligning/calibrating nozzles is a pain in the bottom!

The solution is a loading/unloading system. Some time ago, I started such project, which uses a passive splitter: https://cad.onshape.com/documents/b90810c14902ce503207cb80/w/6221497860f2cc25eada08eb/e/d0cdf6f83c89dd6336161e65 Reducing it to 2 colors only would be very easy. It does not require any additionnal electronic, and a Duet2 board is enough to drive all motors.

Even if I didn't really use it, I have all files for the Duet switching tools. The big issue is to ensure filament is at the correct position. It would need some endstops to do that.

Another great project (and fully functionnal), is Smurf: there is a version with passive splitter too.

-

@fma said in To print in two colors with direct drive & Duet2WiFi:

@the_dragonlord I agree, aligning/calibrating nozzles is a pain in the bottom!

The solution is a loading/unloading system. Some time ago, I started such project, which uses a passive splitter: https://cad.onshape.com/documents/b90810c14902ce503207cb80/w/6221497860f2cc25eada08eb/e/d0cdf6f83c89dd6336161e65 Reducing it to 2 colors only would be very easy. It does not require any additionnal electronic, and a Duet2 board is enough to drive all motors.

Even if I didn't really use it, I have all files for the Duet switching tools. The big issue is to ensure filament is at the correct position. It would need some endstops to do that.

Another great project (and fully functionnal), is Smurf: there is a version with passive splitter too.

But if I'm not wrong this is for a bowden sistem, is it?

-

@fma said in To print in two colors with direct drive & Duet2WiFi:

@the_dragonlord I agree, aligning/calibrating nozzles is a pain in the bottom!

The solution is a loading/unloading system. Some time ago, I started such project, which uses a passive splitter: https://cad.onshape.com/documents/b90810c14902ce503207cb80/w/6221497860f2cc25eada08eb/e/d0cdf6f83c89dd6336161e65 Reducing it to 2 colors only would be very easy. It does not require any additionnal electronic, and a Duet2 board is enough to drive all motors.

Even if I didn't really use it, I have all files for the Duet switching tools. The big issue is to ensure filament is at the correct position. It would need some endstops to do that.

Another great project (and fully functionnal), is Smurf: there is a version with passive splitter too.

If I search for Smurf I find everything but the project....have you got a link?

-

@the_dragonlord said in To print in two colors with direct drive & Duet2WiFi:

But if I'm not wrong this is for a bowden sistem, is it?

Nope, I used it with a direct drive extruder: the system loads/unloads the filament through the passive splitter, and then disconnect ( active loader is disengaged while printing with this channel).

-

@the_dragonlord said in To print in two colors with direct drive & Duet2WiFi:

If I search for Smurf I find everything but the project....have you got a link?

Sorry, it is SMuFF, not Smurf!!! My bad...

https://sites.google.com/view/the-smuff/home

It uses an external electronic, but I'm pretty sure it can be simplified, to run only with the Duet2.

-

@fma said in To print in two colors with direct drive & Duet2WiFi:

@the_dragonlord said in To print in two colors with direct drive & Duet2WiFi:

If I search for Smurf I find everything but the project....have you got a link?

Sorry, it is SMuFF, not Smurf!!! My bad...

https://sites.google.com/view/the-smuff/home

It uses an external electronic, but I'm pretty sure it can be simplified, to run only with the Duet2.

Thanks....I have to be honest...I've struggled sooo much to build the printer and now I'm "tired" to struggle and I want something so much simpler...I'm realizing I'm asking too much...I'm afraid I will have to wait to have the money for an old Palette2.....sigh sigh

-

@the_dragonlord I know someone owning a Palette2, and he is not happy at all! It is not as reliable as claimed, and have poor support... I think SMuFF is a better and much cheaper project.

-

With an additionnal motor driver, you could simplified my or SMuFF design by using 2 bowden extruders to load/unload the filament. You may still require 2 servos to disengage printing channel, but I read here that someone was using a bowden extruder to help the main extruer, so don't disengage it. Using mixing feature of RRF is a solution to adjust the relative speed of the 2 extruders (main and loader).

I may try this solution, one day (I have aDuex5, so I can have 6 colors), using cheap chineese bowden extruders.

-

@fma said in To print in two colors with direct drive & Duet2WiFi:

With an additionnal motor driver, you could simplified my or SMuFF design by using 2 bowden extruders to load/unload the filament. You may still require 2 servos to disengage printing channel, but I read here that someone was using a bowden extruder to help the main extruer, so don't disengage it. Using mixing feature of RRF is a solution to adjust the relative speed of the 2 extruders (main and loader).

I may try this solution, one day (I have aDuex5, so I can have 6 colors), using cheap chineese bowden extruders.

Thanks for the suggestion....too work to do form me now....as I told I'm a bit tired to spend more time in tuning than printing....for now my "2 colors deisre" will remain....a desire

-

@the_dragonlord there is the option of a mixing hotend e.g. the e3d cyclops? Mixing hotends come with their own fun but as you can vary the mixing ratio, you can print different colours at once, and I believe you might be able to do different materials if their melt temp is similar (e.g. PLA and PVA for soluble supports), though there maybbe some contamination. E3d suggest using is as a bowden as its small and light, but can be done as a direct drive (e.g. the Bondtech X2 extruder). I use the Chimera with a similar setup on my printer (using two BMGs as direct drives).

Alternatively I believe that there are several hotends available on aliexpress etc that have a y-splitter in the heatsink. Not sure how reliable they'll be and you'll need two extruders (same as the cyclops), but might be a neat solution for you?

-

@engikeneer But have you had difficulties to setup the various offset for the Chimera? I mean X and Y offset but Z as well beacuse I can Imagine that it's almost impossible to screw the two nozzles at the exact height....Can you tell me more about your setup? If it's not a problem for you can you give me a couble of photos? (of course take your time, I'm not in hurry)..E3D has developed the Cyclops wich ALMOST seems what I need...but the weight should be the problem...

-

@the_dragonlord said in To print in two colors with direct drive & Duet2WiFi:

.E3D has developed the Cyclops

I had massive leaking problems with a Cyclops-clone. You could say, it just a clone, but IMHO it's a systematic problem.

Usually the nozzle and the heatbrake seal each other by tightening the screws, but with the cyclops the threads for nozzle and heatbrakes have to seal everything. That doesn't work in my case. -

@o_lampe uh....I'm starting to think about Chimera and Cyclops...I've seen that with Cyclops you HAVE ALWAYS to have two filaments loaded regardless you print in one or two...from this aspect Chimera will be defnitely better but I'm worried about the needed precision for the various nozzles offsets...Chimera on the other side has the great great advantage you don't need to set up a purge tower for every print and this saves a lot of filament...

-

@the_dragonlord

They're both problematic in one or the other way. I've modified my CoreXY printer to have two independent tool heads. Now I can park the unused tool and don"t risk it scratching off the fresh print... I had to switch over to a Maestro with 2 more drivers onboard, but a DuetWiFi can do the trick, too. (with an external driver)

Ofcourse, setting up this printer takes alot of tuning and that's what you don't want... -

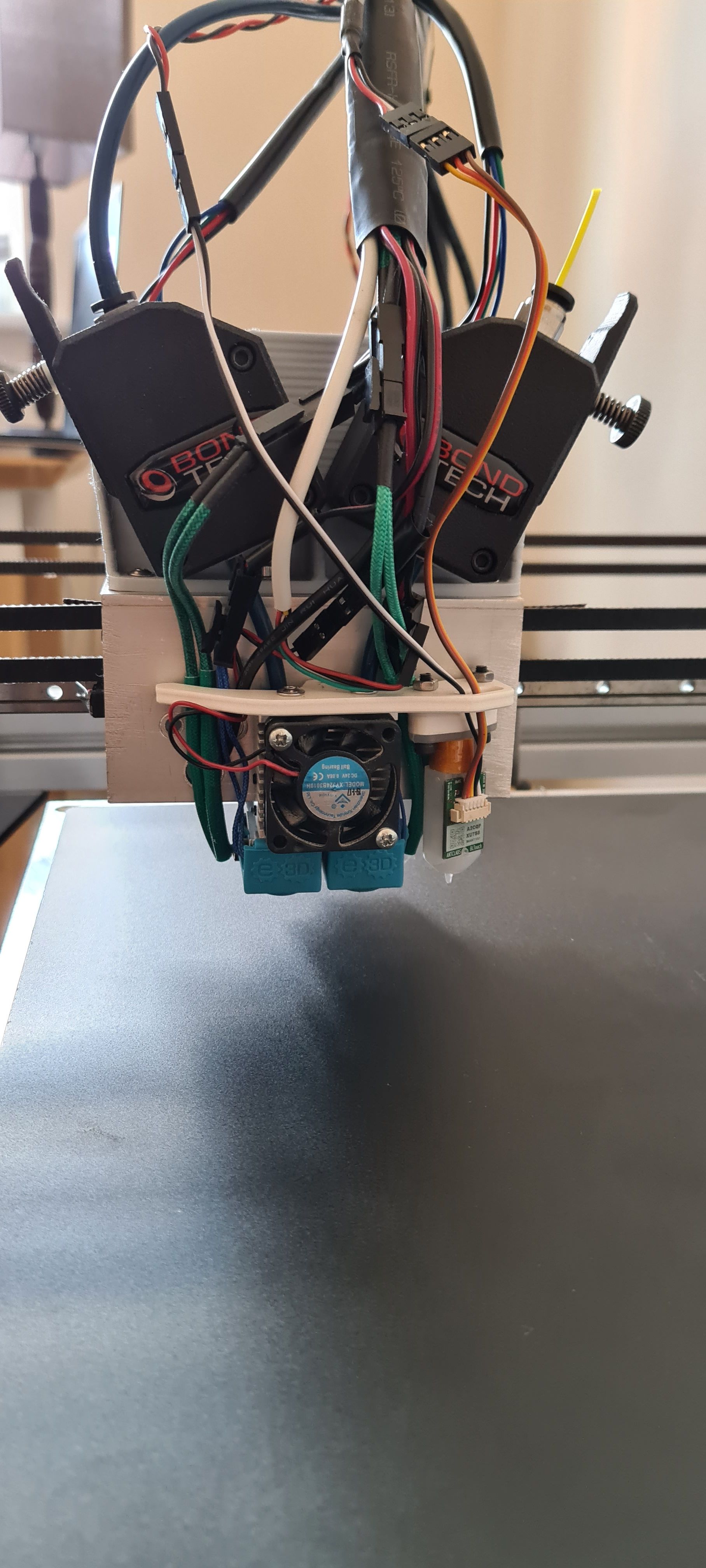

@the_dragonlord here's a picture of my setup with my chimera.

95% of the time, I print with only one nozzle, so simply drop that nozzle 0.5mm lower than the other and don't have to worry about the other nozzle scraping. Left nozzle is a 0.5mm for big prints, right one is 0.3mm for small detailed prints. I do have to reset the BLTouch trigger height when I do this, but would have to if I swapped the nozzle on a standard V6 anyway so it's not too bad.

When I do want to print with both nozzles, I do spend a bit of time getting them the right height. Typically I loosen both heatbreaks, then bring the bed up so they're both sitting on it flat and tighten them up. I'll then do a quick test print to check they're aligned okay (and double check the xy offsets) before doing my actual print. It's a bit of faff that takes half an hour, but isn't too bad.

For the actual print, I've found I do get some issues the ooze from the unused nozzle. Some filament brands tend to be better than others so I tried a few before settling on one that I'm happy with.

There's a tradeoff in the standby temperature of the unused nozzle. Lower standby temperature means less ooze, but longer tool changes (a 10s tool change to heat the new tool on every layer adds an hour to the print time over a 600 layer print!). At first I tried with only a 5deg drop, but now I run about 20deg and try to print as cold as I can get away with.

I also use an ooze shield around the object, in part to wipe any ooze off the incoming nozzle, but also to make sure it is properly primed if it has oozed. This does mean a waste quite a bit of filament...

In general, I do get some artefacts on the top surface of the print from the unused nozzle dragging over. It's generally better if I print on larger layer heights (>0.2mm). If I can get away with it, I'd typically print something in two parts and glue them together though as it usually works out quicker.

I also have a (clone) cyclops in my drawer which I'm going to try out at some point, as much for the fun of it as anything! Will be interesting to see how that performs.

If I were to build the printer again and had the money, I would probably choose to go for a toolchanger setup. But that's probably because it adds another level of complexity and I love tinkering with the printer as much as actually printing with it

I'm also considering trying a y-splitter on the bowden feed for my delta printer to see how well that works... I don't think there's an easy/cheap way to do multi colour/material printing

I'm also considering trying a y-splitter on the bowden feed for my delta printer to see how well that works... I don't think there's an easy/cheap way to do multi colour/material printing -

@the_dragonlord getting back to your OP and your desire to use a single nozzle but with direct drive, then AFAIK there isn't a two input one output hot end where the inputs are spaced sufficiently far enough apart to accommodate two "normal size" extruders in true direct drive configuration. You might just get away with it by using "remote" flex drive extruders such as the Zesty Nimble.

Apart from that, you'll have to compromise. You could use very short Bowden tubes as others have pointed out. But if you really don't want to that, then you only other option is to make a tool changer.

-

I've been running a Cyclops+ for the last few months. My tear stained diary is full of the challenges I've had and ultimately ended in failure. Full disclosure it's not entirely genuine, the nozzle and heater block are clones, the rest genuine. A lot of the tribal knowledge surrounding other mixing hotends (Diamond primarily) didn't apply to Cyclops+ in my experience. The biggest problem is that this hotend wasn't designed for mixing and has lots of extrusion irregularities when trying to mix (I confirmed this with E3D). It's possible that my clone heater block is faulty but I haven't decided if I want to put more effort into it, it's been a few months and attrition is setting in.

In regards to your extruder problem, have you seen this? https://www.bondtech.se/product/bmg-x2-extruder/ it's made specifically for Chimera/Cyclops (plus and non-plus)