Missing Steps - Cant Print SpreadCycle StealthChop tuning help

-

@dc42 Used the calculator and used some conserative settings:

M92 X80.00 Y80.00 Z320.00 E711.97 ; set steps per mm M566 X600.00 Y600.00 Z50.00 E2000.00 ; set maximum instantaneous speed changes (mm/min) M203 X8000.00 Y8000.00 Z1000.00 E5000.00 ; set maximum speeds (mm/min) M201 X2000.00 Y2000.00 Z200.00 E1000.00 ; set accelerations (mm/s^2) M906 X400 Y400 Z600 E400 I75 ; set motor currents (mA) and motor idle factor in per cent M84 S120 ; Set idle timeout M572 D0 S0.061 ; Pressure advanceThe result is better in terms of the amount of layer shifts. But it still happened two times during the print. With the Duet 2 Wifi I never configured any Stealthchop/Spreadcycle settings but due to the other drivers on the Mini 5 I had to because steppers sounded terrible.

Is there anything else I can try? Thanks for your help in advance.

-

@martinnyhc said in Missing Steps - Cant Print SpreadCycle StealthChop tuning help:

With the Duet 2 Wifi I never configured any Stealthchop/Spreadcycle settings

That's because the TMC2660 driver chips on Duet 2 WiFi only have spreadcycle.

Most noticeable for noise is spreadcycle at standstill. To test if your missed steps are an issue with stealthchop, you can set the drivers to spreadcycle only when moving, and stealthchop when the are stationary. To do this, set the V parameter in M569 for X and Y to a relatively high number, something like V2000, then send M569 P0 and check the 'tpwmthrs' response. When I do this, I get 'tpwmthrs 2000 (2.3 mm/sec)', but it depends on your microstepping and steps per mm. Adjust the V parameter until it is somewhere between 5 and 10mm/s. Use this speed as it's below your M566 instantaneous speed setting of X600 Y600 (which is 10mm/s).

Alternatively, switch it to spreadcycle for a test with M569 P# D2 (where # is the driver number).

Ian

-

@droftarts Already tried D2. The problem is that as soon as I use D2 or D3 without a V value or V higher than 0 both steppers are sound like they are going to explode in a few seconds. And beside of that i cannot get rid of the layer shifts completely.

-

@martinnyhc What steppers are you using on X and Y?

Ian

-

@droftarts 14HS17-0504S

-

@martinnyhc These? https://www.omc-stepperonline.com/nema-14-bipolar-1-8deg-23ncm-32-6oz-in-0-5a-7-5v-35x35x42mm-4-wires.html

The inductance and phase resistance strike me as being very high:

Phase Resistance: 15ohms

Inductance : 26mH ± 20%(1KHz)High inductance is usually bad for high speed; see https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors#Section_Inductance

When the bangs happen, is it during fast travel moves? But your Duet 2 coped fine with the same settings?If yes, I think @dc42 will need to take a deeper look at this.

Ian

-

@droftarts It is my "small printer" which is a Voron0 and these steppers are standard for the printer. I'm not really printing fast currently. Max 60mm/s and yes, with the Duet 2 and the same settings everthing was fine. Don't changed anything else except changing the board.

-

Oh yes....and I added a SBC. That's the reason why i changed the board

In the meantime I checked for mechanical issues once again but all seems to be fine.

Why did I touch a running system when I really need to print a lot of stuff. Damn.....

-

To isolate the problem I now disconnected the SBC and tried in standalone mode. Nothing changed.

-

@martinnyhc you’ve got some long SD card read times in your M122 reports, which I assume were taken during printing:

SD card longest read time 99.5msThis was caused by the bed heater PWM duty cycle last time. @dc42 had a firmware version with some extra diagnostics to track this down, by showing the percentage of time each task in the M122 report was taking. It might be needed again to track down this issue.

Ian

-

@droftarts Ok...wait...i'm running the SBC via network file system. But...I don't think that this could be the problem. If I run either in standaone or SBC mode nothing changes. Right?

And if there would be a data latency then I would see also other effects.

-

@martinnyhc said in Missing Steps - Cant Print SpreadCycle StealthChop tuning help:

@droftarts 14HS17-0504S

Those are a terrible choice of motors for a 3D printer. I am very surprised that the Voron design page suggests them. IMO they have made a big mistake. With such a high inductance, it is not at all surprising that the TMC2209 drivers are having problems driving them quietly in spreadCycle mode. I am surprised that the TMC2660 drivers on the Duet WiFi didn't have trouble with them too. The Voron 2 design recommends completely different stepper motors with lower inductance, so it is not comparable.

Even the kit of Voron 0 motors I found at https://hobby-store.co.uk/stepper-motors/nema-14-stepper-motor-kit-for-voron-0.html had better motors then that (14mH, almost 50% lower inductance).

I presume you are supplying 24V power to the Duet 3 Mini. With those motors, you have no hope at all at 12V.

In your homing sequence, are you executing the correct stealthChop tuning procedure?

If you are already executing the correct tuning procedure, then here are some suggestions:

- Reduce the maximum speed further, e.g. to 6000mm/min.

- It's possible that you may be able to make spreadCycle mode quieter by adjusting the hysteresis parameters.

- Try to find another Voron 0 user with the same motors as you and TMC2209 drivers, who isn't having problems with them. Find out what speed and accelerations settings they are using, also the TMC2209 register settings. Then replicate those settings.

- Failing that, change the motors for higher current/lower inductance ones.

-

@dc42 said in Missing Steps - Cant Print SpreadCycle StealthChop tuning help:

Those are a terrible choice of motors for a 3D printer. I am very surprised that the Voron design page suggests them.

For what it's worth, the current recommendation for Voron 0 steppers is 14HS20-1504S which are much better at 3.8mH. The old motors work fine on a Duet2 Maestro but only in Stealthchop mode, they sound awful in Spreadcycle (now I know why!). I don't believe there were many choices commonly available when the printer was designed.

-

This was the default config for V0's back when they were announced over a year ago.

Now the 0.1 was announced and steppers got upgraded to a bigger version (35STH48-1684AHVRN).

That said, the default config assumed using an SKR E3 mini that was running 2209s. @MartinNYHC - try checking the default config for the SKR on voron's github. I've been using that combo of SKR E3 mini v1.2 with those exact steppers - it worked

I did have to bring stealthchop_threshold down to 0 to make them quiet, but otherwise, the printer worked just fine.

I did have to bring stealthchop_threshold down to 0 to make them quiet, but otherwise, the printer worked just fine.Maybe that would give you some starting points for the setup on a duet. I'll be in the same boat soon once I get to the rebuilding part of my V0

-

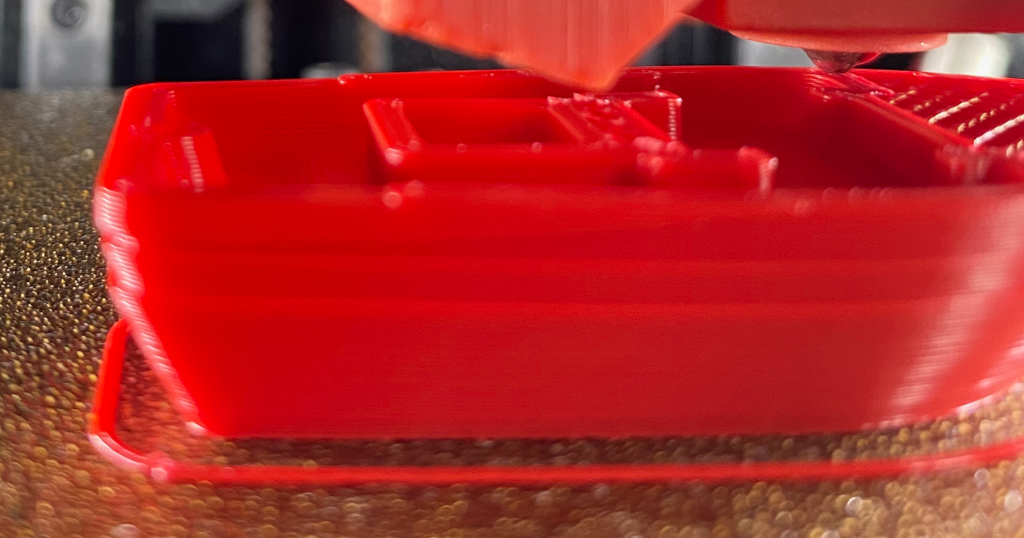

OK, did a lot of tests and the only settings without layer shifts is

M569 P0|1 D3Steppers are quite loud but at least it's working. Will order some new steppers.

-

I dont know if it helps but I am installing reprap on a SKR2 board with tmc 2209 and I have same issue, specially on my bed which runs on a 0.9 degree motor, beside m extrusions are not consistence either. you guessed it right, there is a 0.9 degree motor on extruder. now good thing about SKR 2 is that I can go back and fort with marlin and reprap and compare. this is definitely firmware issue. Reprap runs these motors much quitter and cooler while marlin runs warm and a little noisy. but marlin runs very solid and sound is not really that bad. this tells me reprap and marlin use different pwm settings on stealthchop and marlin made some sacrifice in noise to gain some stability.

-

@sinole Are you sure you are running the steppers at the same current setting with Marlin and RRF? What values are you using in each?

-

@gloomyandy I divide my rated motor current by 1.414 and I use that number * 0.8, I have posted same question on your Github btw. for example for my 17HM19-2004S1 motor which is rated at 2A I use 1.25 A

in firmware.

dc42 says that 2209 have issue with 0.9 degree motors because they have high inductance, but this motor have less inductance than some 1.8 motors , that is why I chose it.I don't have access to my config at the moment but I want to post it for you and I appreciate if you take a look at it.

-

@sinole You didn't answer my question though. What current settings did you use in Marlin and what did you use in RRF?

-

@gloomyandy the current setting that you told me seems to be working better, motors runs a bit hot though. I don't think my z motors were really designed for 1 amp per LDO datasheet when I bought them, hey get scalding hot even when I set them at 450 on reprap.