Vertical banding on COREXY machine

-

@zabana CoreXY drives parallel to x and y axes with both motors and so maybe you have a mismatch (belt tension?) between the two motors.

Do you get the same artefact on a wall that is oriented at 45 degrees to the axes?

-

@mjlew I already checked it and the two belts have the same tension and are parallel like it should be.

Also tested in normal position and rotated 4t -

@dad003 will double check it again, but I am afraid that is not the case, z axis is driven by two 1605 leadscrews per side with two linear mgn12 rails on each side as well, so it is pretty stable and there is no wobling in z anyway as should be if it is the case. Also Z axis is not moving when printing on x and y so should not affect and be responsible for the banding in my opinion.

-

Hi!

I did new test with no conclusion but I read abother user post and it gave me some ideas. I took pics of the single perimeter prints and I checked that is not waving on the perimeters due belt or pulleys I am afraid, it is related to an uneven extrusion I guess.

It seems the extrusion is like pulses, 3 per mm and so the waving.

I checked old prints and less relevant but the pattern was there, the only change is the extruder stepper and bowden to direct. Old stepper was the 25mm pancake with bmg and the new one is the nema 14 rounded with 10 teeth pinion instead the 17 bmg one. The old bowden was less than 6cm and now is direct. The gears are the same because new extruder is the sherpa mini.Does anyone know why the 3:1 pattern maybe?

-

@zabana said in Vertical banding on COREXY machine:

It seems the extrusion is like pulses, 3 per mm and so the waving.

Just wondering if that's related to geared extruders? The straight pinion and spur gear producing nonlinear torque translation??

Angled gears or good ol' direct drive might cure that. -

Can you give us a closer look at your extruder?

-

Could this be affected by pinch roller pressure on the filament? It seems to me that the extruder gears are likely to be a lot smoother than the drive gear(s) biting into the filament.

The effect would probably vary with filament type (PLA seems harder than ABS and PETG). It would be easy enough to test. Try the print at one tension setting and then loosen or tighten the tension and run the same print again.

-

@zabana Yep, looks just like mine. Still haven't found a problem, but I'm suspecting not mechanical after weeks of work. Some say get Klipper.

-

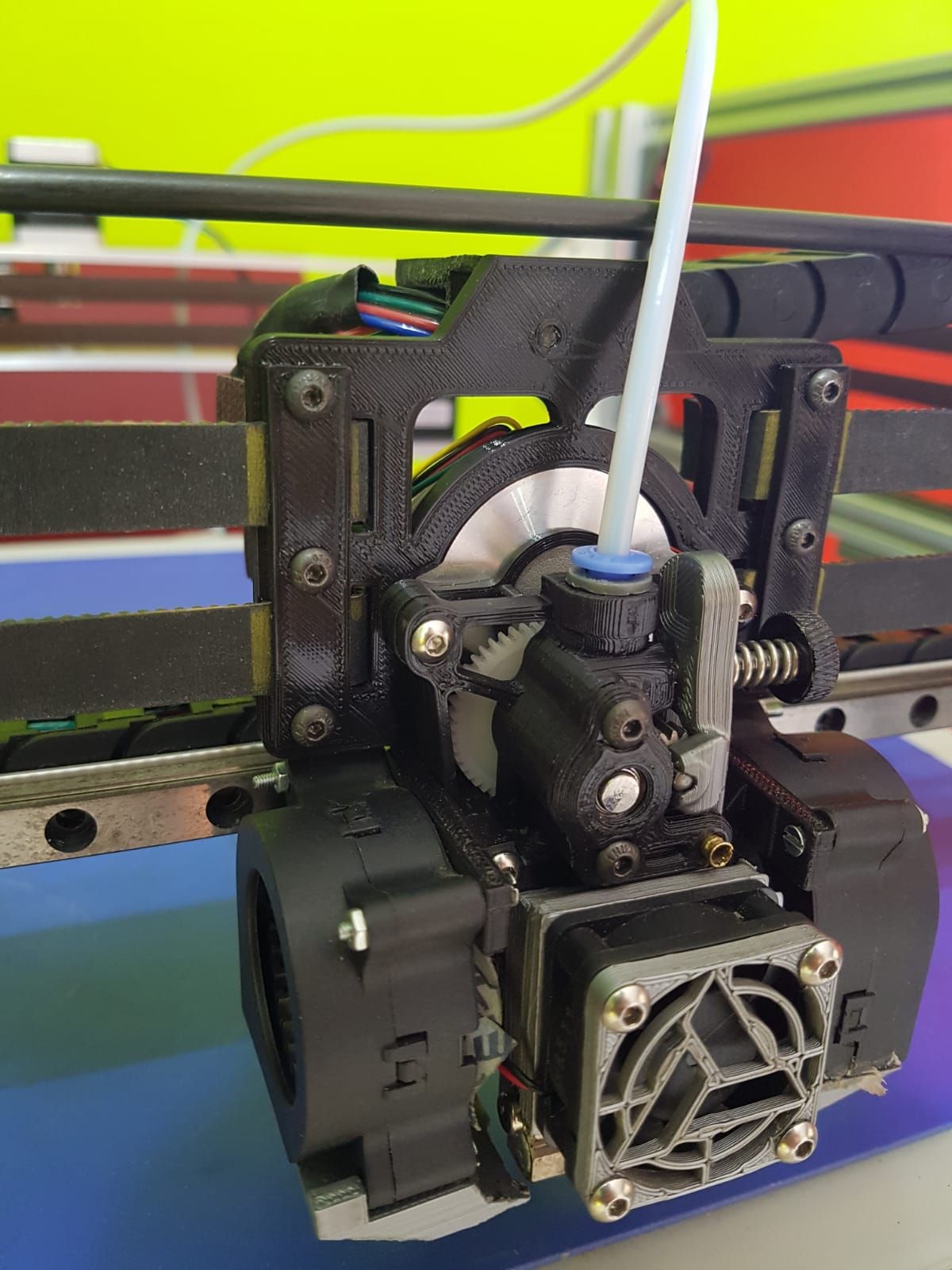

@phaedrux sure I can

It is a sherpa mini, but i modded it to integrate in to the carriage for weight reduction.

I also yesterday replaced the bearings and the gears to a better newer ones I had here because just in case...

-

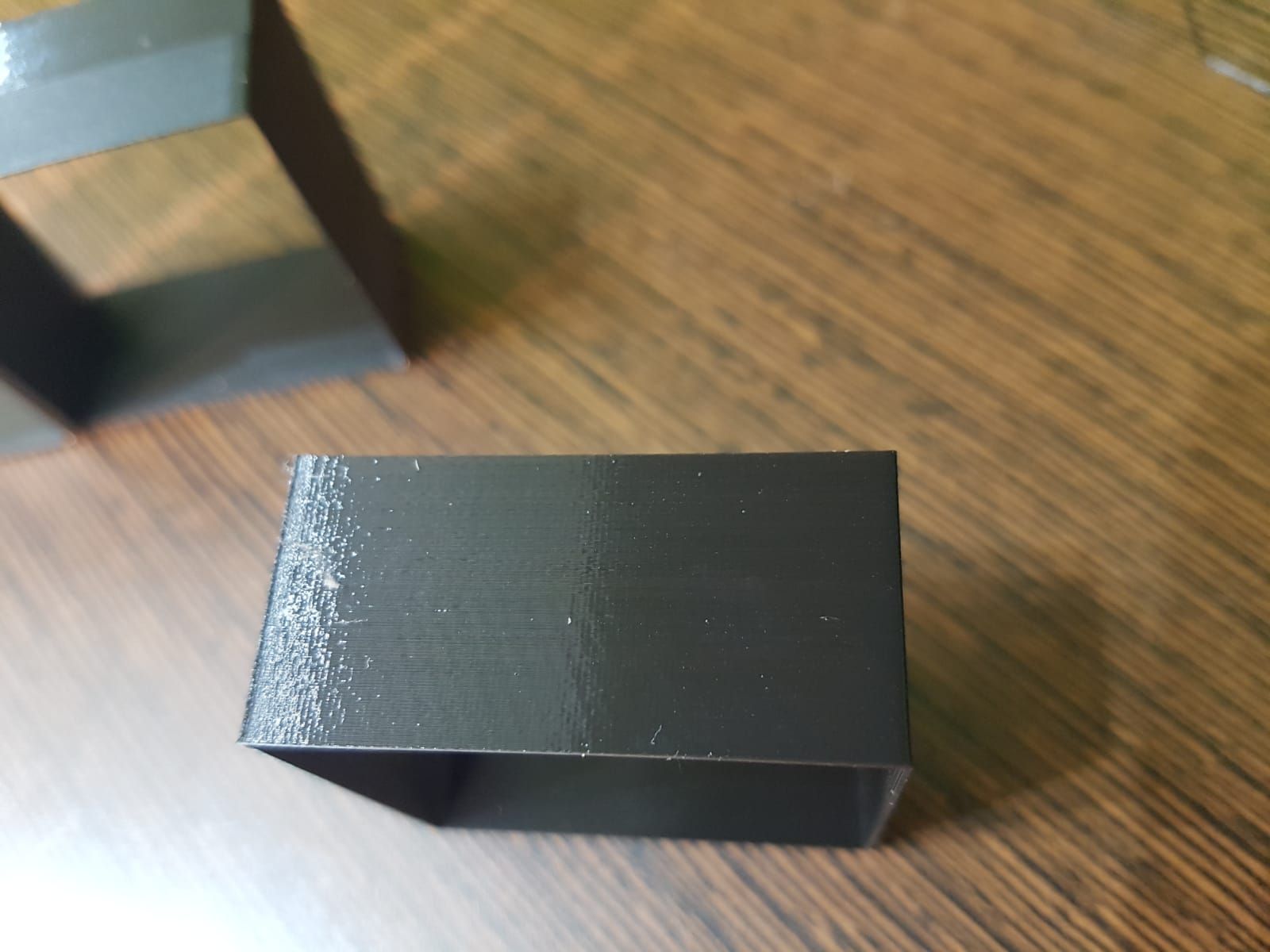

I did a few tests yesterday, I updated the steps from 1401 @ 1/32 to 1404 so at full steps is a round number but it did not helped.

Also did a test printing 3 squares, all of them 40x40x20, first half 30mm/s and second half 60mm/s, at 0.1 0.2 and 0.4 layer height. The 0.1 has no much difference, the 0.2 has better perimeter at higher speed and the 0.4 is the winner, the slow part almost doesn't show the issue and the fast one shows nothing at all.

The nozzle is a 0.4mm one

So I am more than convinced that it is related to the extruder at slow speeds but don't know why yet...Here are some pics

-

@donstauffer I read about klipper but not sure I want to mess with a new firm yet...

-

@mrehorstdmd said in Vertical banding on COREXY machine:

Could this be affected by pinch roller pressure on the filament? It seems to me that the extruder gears are likely to be a lot smoother than the drive gear(s) biting into the filament.

The effect would probably vary with filament type (PLA seems harder than ABS and PETG). It would be easy enough to test. Try the print at one tension setting and then loosen or tighten the tension and run the same print again.

The BMG dual gears might have an influence too. Depending on the pinch roller pressure they mesh in different ways.

Also the bearings and the 'lightweight' housing can cause issues. (I always wondered, why the original BMG housing is so bulky) -

@zabana

Finding the sweet spot between too slow and too fast is one step on the learning curve. And it can change, when you set different jerk settings. -

@o_lampe dont know but after more than 10 years printing I do prefer certain perimeters slow at 30 for quality printings

-

I had the same problem with artifacts in my prints. I found that even "higher grade" Bondtech drive gear clones sometimes have severe runout. Upgrading to genuine Bondtech gears solved the problem. They are really worth the price.

-Max

-

@maxgyver said in Vertical banding on COREXY machine:

drive gear clones sometimes have severe runout.

That's definitely worth looking for, but a runout wouldn't cause such fine lines. That would show up twice per turn of the drive gear.

With the right formula it would be possible to calculate where the problem is.

Microsteps, gear ratio, drivegear diameter, filament diameter, extrusion width, layer height vs. vertical line distance. -

@maxgyver that's something I am thinking about to buy, also ceramic bearings so the full setup will be top notch but I am afraid more money expended with same result as it was to purchase genuine LL gates idlers and pulleys

-

@o_lampe as time pass and the more test I do I am more convinced that thus is something related on how the firmware process small ammounts of filament extrusion and send the steps pulses to the stepper, because if the requested ammount to ve extruder is the same but faster seems to be ok or if the ammount to be extruded is higher due to 0.4 layer height instead 0.2

Maybe someone can give light about it... -

@zabana said in Vertical banding on COREXY machine:

@o_lampe as time pass and the more test I do I am more convinced that thus is something related on how the firmware process small ammounts of filament extrusion and send the steps pulses to the stepper, because if the requested ammount to ve extruder is the same but faster seems to be ok or if the ammount to be extruded is higher due to 0.4 layer height instead 0.2

Maybe someone can give light about it...Maybe inertia at high speed solving a lack of microstepping torque at slow speed?

-

@zabana

If it turns out, Klipper produces better results even without acceleration sensor/input shaper, it would be interesting to compare the e-step pulses on a scope. It can't be hardware related then, so it's in the code. Although @droftart confirmed, both FW use the same default settings for stealthchop: it's what you make of it...

Faster extrusion makes the driver change from stealthchop to spreadcycle mode and suddenly your result looks better...? Why can't we switch off stealthchop for extruders?