Verifying mesh levelling

-

-

@jay_s_uk Thanks

-

@bstump said in Verifying mesh levelling:

this is why I suggested doing a mesh of a smaller area of your printer where you will print a part and see if there is improvement.

We can try this on the worst area of the bed.

It's adjusting the position less each layer than the measured amount over the distance set for the taper. If you use 10mm, at 5mm height it will have 50% less compensation effect such that by 10mm there is no compensation at all. If you set the taper too low, it will be reducing the compensation too much for what you need.

I can understand at height this being the case, but the very first layer is different with the Taper on vs with the Taper off. I would not expect anything noticeable in the way of a difference between Taper on and Off for the first layer. But there is.

What did you have taper set to? There's only so many layers to apply the taper, the first layer isn't immune. Sounds like you might need a much larger taper height.

-

@phaedrux 10mm or about 2% per layer adjustment. at a 0.2mm layer height nor bed level variation, that ain't much.

-

@bstump said in Verifying mesh levelling:

that ain't much.

But apparently enough to make a difference.

-

@phaedrux said in Verifying mesh levelling:

@bstump said in Verifying mesh levelling:

that ain't much.

But apparently enough to make a difference.

So what taper do you suggest related to the med level deviation?

-

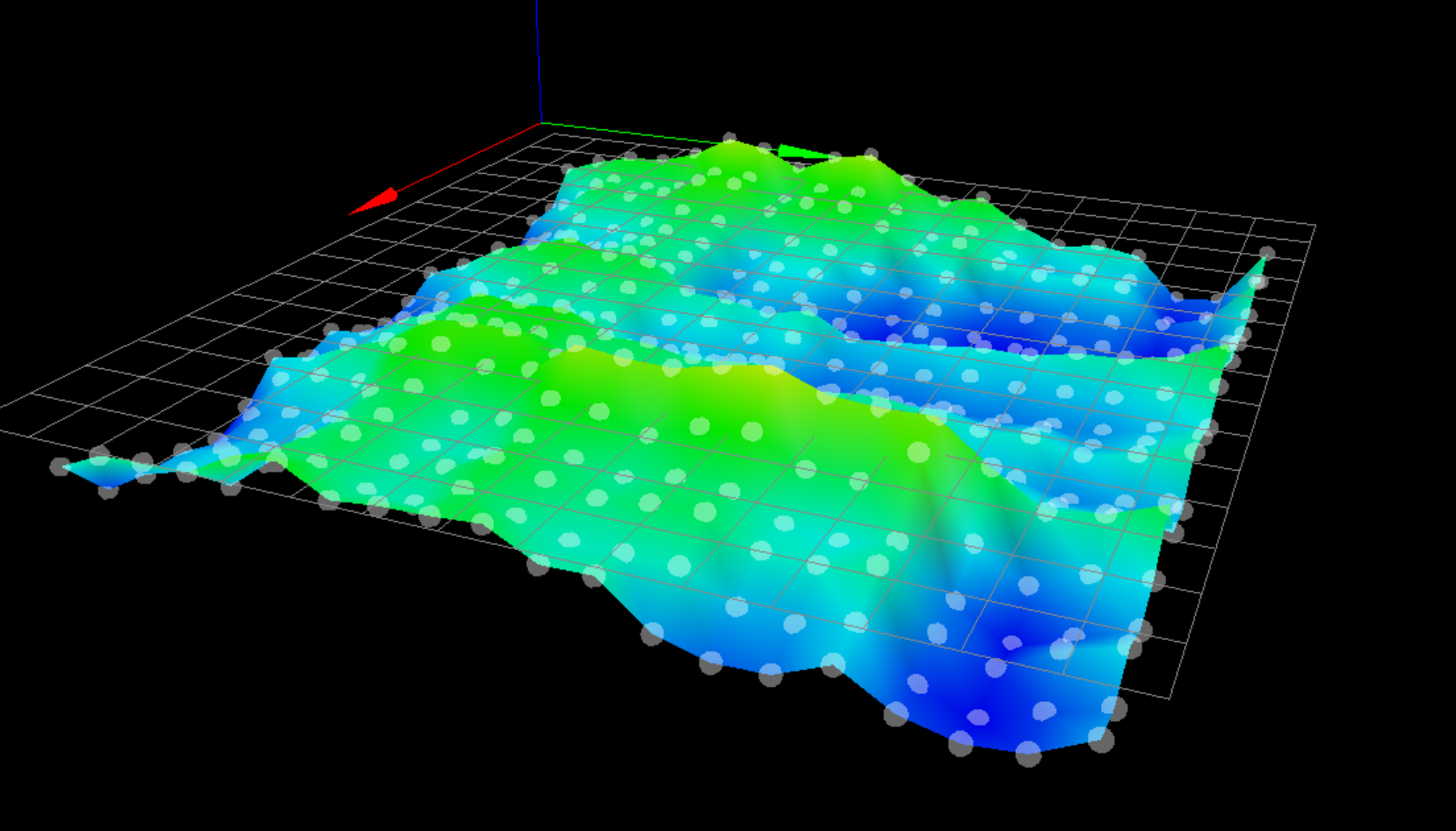

@bstump Post an image of your current heightmap with the values shown.

-

@phaedrux said in Verifying mesh levelling:

@bstump Post an image of your current heightmap with the values shown.

-

That center panel looks low given when this was generated. I am not sure the bed was fully heated or if the ceter was heated sufficiently.

-

With a bed like that I'd probably leave taper off entirely unless you're more concerned about wear and tear on the z axis. Otherwise try 50mm

Take a look at this to see if it might fit into your work flow.

https://forum.duet3d.com/topic/15302/cura-script-to-automatically-probe-only-printed-area

This way you could maximize the 440 points into the exact area you're printing on, with the downside of needing to probe before each print. Though if the area is smaller you could probably get away with fewer than the full 441.

Can you also post your config.g again? I can't seem to find it scrolling up. There are potentially improvements we can make to the probing settings.

-

@phaedrux said in Verifying mesh levelling:

@bstump Post an image of your current heightmap with the values shown.

I am wondering if the taper has some limits built in for how much or how little it can handle. Maybe given the overall bed size the variation is too much to deal with with one are it is apply a 0.00001mm taper adjustment and at another it needs a 0.01 per layer.

-

-

@fcwilt said in Verifying mesh levelling:

I don't use taper at all.

Frederick

We do jigs and fixtures and prototypes with this. Or that is the intention. given the flatness of the best not using taper could be an issue. But so is not adhering.

-

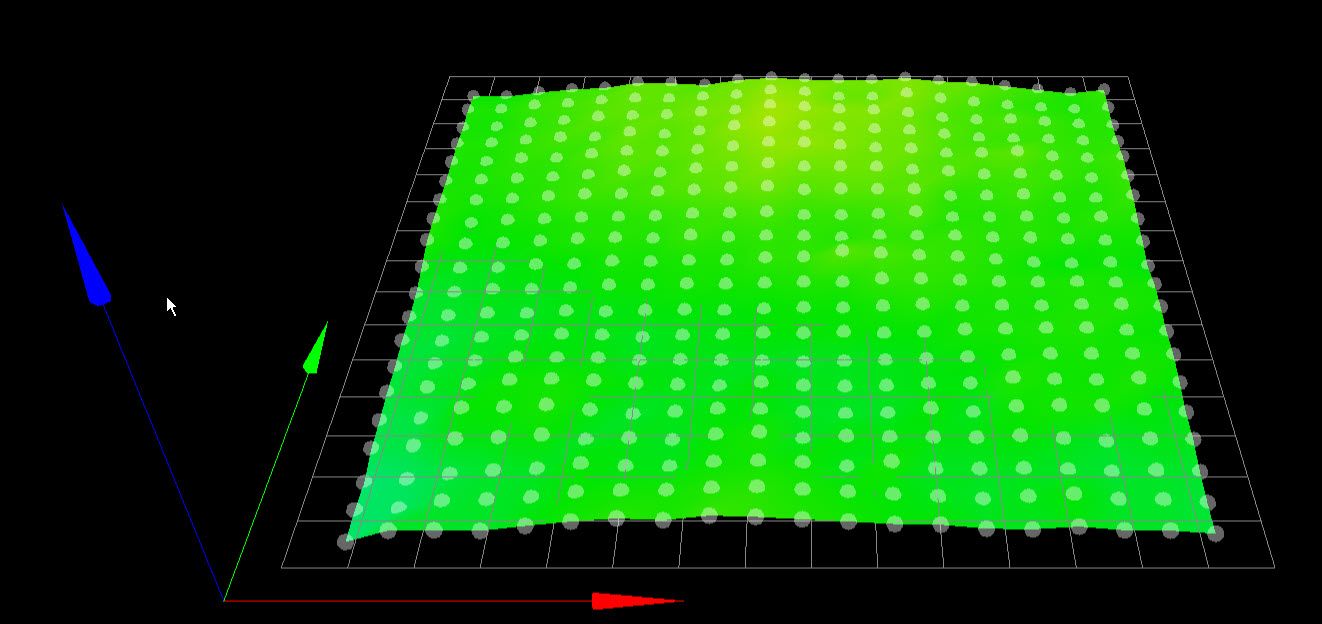

I use cast tool plate for the beds of my printers which from my supplier is spec'd to be flat within 0.4 mm but is usually much better.

I have found that bed adhesion is affected by many factors but these are what work for me:

- use the best cast tool plate you can find

- get the bed level within 0.005mm

- use 400 point mesh compensation

- use a first layer printing speed 10%-20% of the normal print speed

- turn off the part cooling fan for the first layer

Frederick

Here is the height map from my modified FT5 printer:

-

@fcwilt said in Verifying mesh levelling:

use the best cast tool plate you can find

1 square meter of cast tooling plate may be a bit expensive.

-

@phaedrux said in Verifying mesh levelling:

@fcwilt said in Verifying mesh levelling:

use the best cast tool plate you can find

1 square meter of cast tooling plate may be a bit expensive.

Very - but I don't see much point in building such a printer if it cannot be used to print things.

My goto vendor would want appx:

- $260 for 3000mm by 3000mm by 6mm

- $270 for 3000mm by 3000mm by 12mm

- $470 for 3000mm by 3000mm by 24mm

I find it interesting that 12mm is close in price to 6mm.

Frederick

-

@fcwilt said in Verifying mesh levelling:

I use cast tool plate for the beds of my printers which from my supplier is spec'd to be flat within 0.4 mm but is usually much better.

I have found that bed adhesion is affected by many factors but these are what work for me:

- use the best cast tool plate you can find

- get the bed level within 0.005mm

- use 400 point mesh compensation

- use a first layer printing speed 10%-20% of the normal print speed

- turn off the part cooling fan for the first layer

Frederick

Here is the height map from my modified FT5 printer:

Always 400 point mesh.

The first layer speed is typically ~50% of the other layer speed.

We have 0% fans for the first 10 layers to improve bed adhesion and reduce warping.

Our bed is made from three rectangular Aluminum plate. And on that are three PEI sheets. The overall bed if 1010 x 1010, and suffers for bubbles in the attachment of the PEI sheet to the bed.

-

I am very intrigued by this post where several made scripts for Curs, S3D, and Slicr to probe only the area under the actual print. Not being a coder I need to modify moth the Cura and Simplified #d ones to keep the number of probe points under 400 and not probe less than about 10mm spacing.

I think this may solve our issues. Not sure how this would be applied when you have a multi part print where ideally it probes under each individually.

https://forum.duet3d.com/topic/15302/cura-script-to-automatically-probe-only-printed-area

-

@phaedrux said in Verifying mesh levelling:

With a bed like that I'd probably leave taper off entirely unless you're more concerned about wear and tear on the z axis. Otherwise try 50mm

Take a look at this to see if it might fit into your work flow.

https://forum.duet3d.com/topic/15302/cura-script-to-automatically-probe-only-printed-area

This way you could maximize the 440 points into the exact area you're printing on, with the downside of needing to probe before each print. Though if the area is smaller you could probably get away with fewer than the full 441.

Can you also post your config.g again? I can't seem to find it scrolling up. There are potentially improvements we can make to the probing settings.

Thanks on that, I found it also. Very intriguing. See my comment above.

-

@phaedrux said in Verifying mesh levelling:

With a bed like that I'd probably leave taper off entirely unless you're more concerned about wear and tear on the z axis. Otherwise try 50mm

Take a look at this to see if it might fit into your work flow.

https://forum.duet3d.com/topic/15302/cura-script-to-automatically-probe-only-printed-area

This way you could maximize the 440 points into the exact area you're printing on, with the downside of needing to probe before each print. Though if the area is smaller you could probably get away with fewer than the full 441.

Can you also post your config.g again? I can't seem to find it scrolling up. There are potentially improvements we can make to the probing settings.

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Thu Jun 24 2021 09:31:20 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"modix_big_meter" ; set printer name ; Network M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; physical drive 0 X1 reverse M569 P1 S1 ; physical drive 1 X2 forward M569 P2 R-1 ; Physical drive 2 not used M569 P3 S1 ; physical drive 3 E0 forward M569 P4 S0 ; physical drive 4 E1 reverse ; additional drives on duex5 expansion board M569 P5 S0 ; Physical drive 5 Y reverse M569 P6 S0 ; Physical drive 6 Z1 (0,1000) reverse M569 P7 S0 ; Physical drive 7 Z2 (0,0) reverse M569 P8 S0 ; Physical drive 8 Z3 (1000,0) reverse M569 P9 S0 ; Physical drive 9 Z4 (1000,1000) reverse M584 X0:1 Y5 Z6:7:8:9 E3:4 P3 ; map motors to axis M671 X-181:-181:1049:1049 Y1066:-58:-58:1066 S10 ; CCW positions of Z motors M350 X16 Y16 Z16 E16 U16 I1 ; Configure microstepping with interpolation M92 X100.00 Y100.00 Z2000.00 E412.32 U100.00 ; Set steps per mm ;M566 X240 Y360 Z30.00 E120.00 U240 P1 ; Set maximum instantaneous speed changes (mm/min) M566 X120 Y360 Z30.00 E120.00 U240 P1 ; Set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z200.00 E1200.00 U9000.00 ; Set maximum speeds (mm/min) ;M201 X1000 Y1000 Z120.00 E250.00 U1000 ; Set accelerations (mm/s^2) M201 X500 Y1000 Z120.00 E250.00 U1000 ; Set accelerations (mm/s^2) M204 P500 T1000 ; Set print and travel accelerations (mm/s^2) M906 X1800 Y1800.00 E1000.00 U1800 I30 ; Set motor currents (mA) and motor idle factor in per cent M906 Z1800.00 I50 ; Set motor currents (mA) and motor idle factor in per cent M84 S60 X Y U E0 E1 ; Set idle timeout - one minute ; Axis Limits M208 X0 Y0 Z0 U0 S1 ; set axis minima M208 X1000 Y1000 Z1000 U1000 S0 ; set axis maxima ; Endstops ; X1 = X end stop low end ; Y2 = Y end stop high end ; U1 = U end stop low end (U is second X) ; S1 = all active high ; no Z end stop M574 X1 S1 P"xstop+e0stop" ; combined X axis endstops M574 Y2 S1 P"ystop" ; Z-Probe M950 S0 C"duex.e6heat" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H5 F120 T9000 R0.7 ; set Z probe type to bltouch and the dive height + speeds ; heater 7 output used for PWM of BL touch (e6 heat) G31 P500 X-14 Y21 Z1.000 ; Set Z probe trigger value, offset and trigger height(Z-offset) M557 X-14:974 Y21:1009 S52 ; Define mesh grid. 400 Points ;M376 H10 ; Height (mm) over which to taper off the bed compensation M376 H0 ; compensation taper disabled TEST ; Heaters M140 H-1 ; disable heated bed (overrides default heater mapping) ; tool 0 heater M308 S0 P"spi.cs1" Y"rtd-max31865" R395 F60 M950 H1 C"e0heat" T0 ; heater 0 uses the e0_heat pin and sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S285 ; set temperature limit for heater 0 to 285C ; tool 1 heater M308 S1 P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e1temp M950 H2 C"e1heat" T1 ; create nozzle heater output on e1heat and map it to sensor 1 M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H2 S285 ; set temperature limit for heater 1 to 285C ; Fans M950 F0 C"fan0" Q500 ; T0 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; T1 ; create fan 1 on pin fan1 and set its frequency M106 P1 S0 H-1 ; set fan 1 value. Thermostatic control is turned off M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S0 H-1 ; set fan 2 value. Thermostatic control is turned off M950 F3 C"duex.fan3" Q500 ; create fan 3 on pin duex.fan3 and set its frequency M106 P3 I-1 ; set fan 3 value. Thermostatic control is turned off M950 F4 C"duex.fan4" Q500 ; create fan 4 on pin duex.fan4 and set its frequency M106 P4 I-1 ; set fan 4 value. Thermostatic control is turned off M950 F5 C"duex.fan5" Q500 ; create fan 5 on pin duex.fan5 and set its frequency M106 P5 S1 H0 T46 ; extruder 0 ; set fan 5 value. Thermostatic control is turned on M950 F6 C"duex.fan6" Q500 ; create fan 6 on pin duex.fan6 and set its frequency M106 P6 S1 H1 T46 ; extruder 1 ; set fan 6 value. Thermostatic control is turned on ; apparently these disabled defines still seize the IO; don't define so we can use for LED later ;M950 F7 C"duex.fan7" Q500 ; create fan 7 on pin duex.fan7 and set its frequency ;M106 P7 I-1 ; set fan 7 value. Thermostatic control is turned off M950 F8 C"duex.fan8" Q500 ; create fan 8 on pin duex.fan8 and set its frequency M106 P8 I-1 ; set fan 8 value. Thermostatic control is turned off ; Tools M563 P0 S"E0 Primary" D0 H1 F0 ; define tool 0, E0 drive, heater 1, fan 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 S"E1 SEcondary" D1 H2 F1 ; define tool 1 G10 P1 X-0.2 Y52.5 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M501 ; load saved parameters from non-volatile memory ; Automatic power saving____________________________________________ M911 S22.5 R29.0 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss. Power Failure Pause ;M591 D0:1 P1 C4 S1 ; Regular filament sensor for E0 and E1 ; disabled, fixme ; _______________GPIOs____________________ ; LED strip on GPIO 'P1', duex fan7 output M950 P1 C"duex.fan7" Q500