Verifying mesh levelling

-

We did my little check and found that the probe offset is compensated for. We also did do some test prints where we turned off Taper and adhesion improved notably. So the questions now are

- Why does the taper adjustment degrade adhesion?

- What is happening in the algorithm that does the taper adjustment that it is not applying a consistent first layer thickness?

** Over 10mm taper ajdustment zone, the per layer adjustment should be ~2% of the needed mesh compensation.

** A pretty small number that should not impact bed adhesion.

Could it be at a mesh point ever 50mm is not enough to properly mesh the bed? Should we try a 900 point mesh vs the 400 point mesh we typically do?

-

@bstump the most mesh points you can have are 441

-

@bstump said in Verifying mesh levelling:

Could it be at a mesh point ever 50mm is not enough to properly mesh the bed?

this is why I suggested doing a mesh of a smaller area of your printer where you will print a part and see if there is improvement.

@bstump said in Verifying mesh levelling:

Why does the taper adjustment degrade adhesion?

It's adsjusting the position less each layer than the measured amount over the distance set for the taper. If you use 10mm, at 5mm height it will have 50% less compensation effect such that by 10mm there is no compensation at all. If you set the taper too low, it will be reducing the compensation too much for what you need.

-

this is why I suggested doing a mesh of a smaller area of your printer where you will print a part and see if there is improvement.

We can try this on the worst area of the bed.

It's adjusting the position less each layer than the measured amount over the distance set for the taper. If you use 10mm, at 5mm height it will have 50% less compensation effect such that by 10mm there is no compensation at all. If you set the taper too low, it will be reducing the compensation too much for what you need.

I can understand at height this being the case, but the very first layer is different with the Taper on vs with the Taper off. I would not expect anything noticeable in the way of a difference between Taper on and Off for the first layer. But there is.

-

@jay_s_uk said in Verifying mesh levelling:

@bstump the most mesh points you can have are 441

Where is this documented? But this is reasonable.

-

-

@jay_s_uk Thanks

-

@bstump said in Verifying mesh levelling:

this is why I suggested doing a mesh of a smaller area of your printer where you will print a part and see if there is improvement.

We can try this on the worst area of the bed.

It's adjusting the position less each layer than the measured amount over the distance set for the taper. If you use 10mm, at 5mm height it will have 50% less compensation effect such that by 10mm there is no compensation at all. If you set the taper too low, it will be reducing the compensation too much for what you need.

I can understand at height this being the case, but the very first layer is different with the Taper on vs with the Taper off. I would not expect anything noticeable in the way of a difference between Taper on and Off for the first layer. But there is.

What did you have taper set to? There's only so many layers to apply the taper, the first layer isn't immune. Sounds like you might need a much larger taper height.

-

@phaedrux 10mm or about 2% per layer adjustment. at a 0.2mm layer height nor bed level variation, that ain't much.

-

@bstump said in Verifying mesh levelling:

that ain't much.

But apparently enough to make a difference.

-

@phaedrux said in Verifying mesh levelling:

@bstump said in Verifying mesh levelling:

that ain't much.

But apparently enough to make a difference.

So what taper do you suggest related to the med level deviation?

-

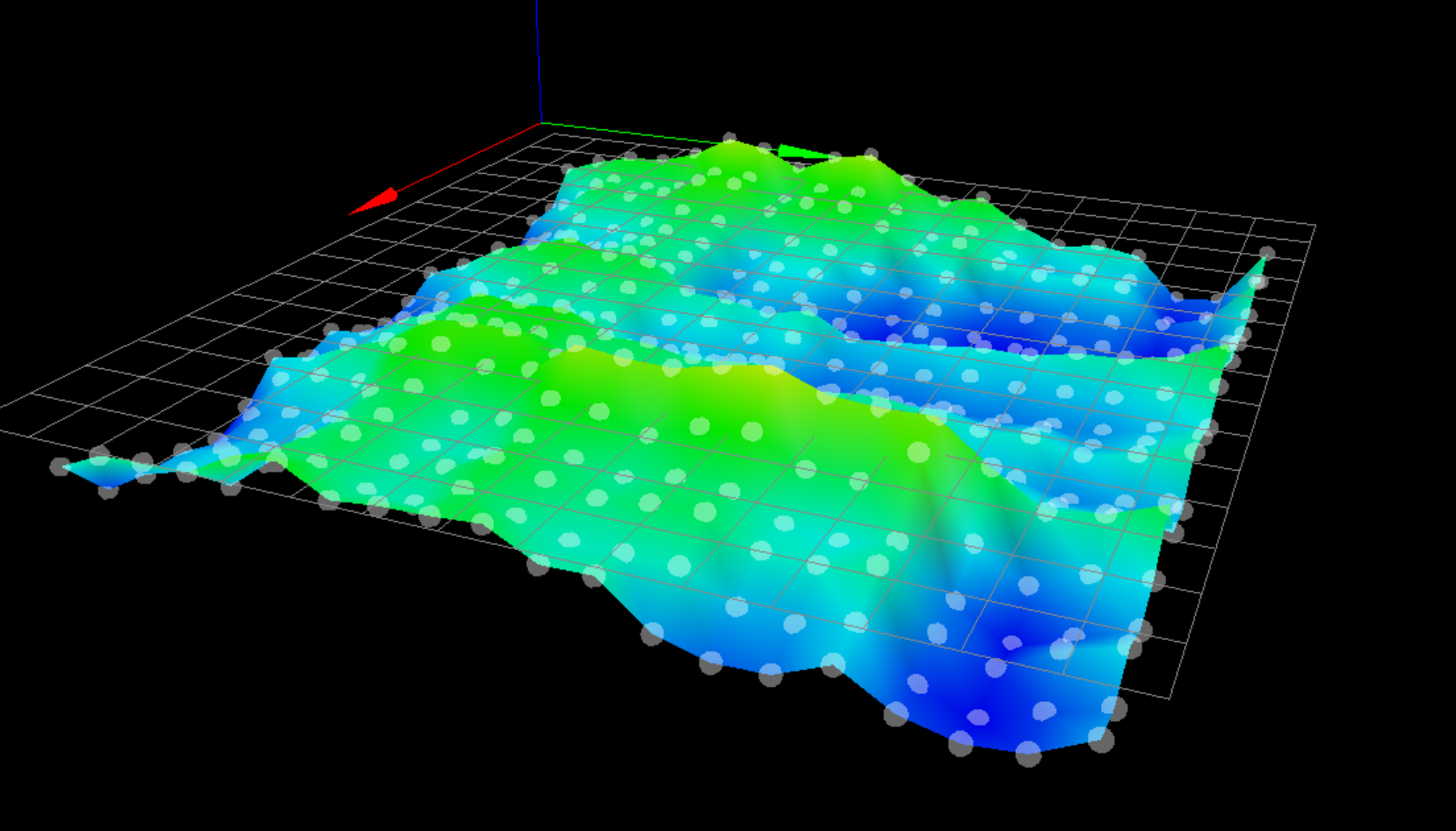

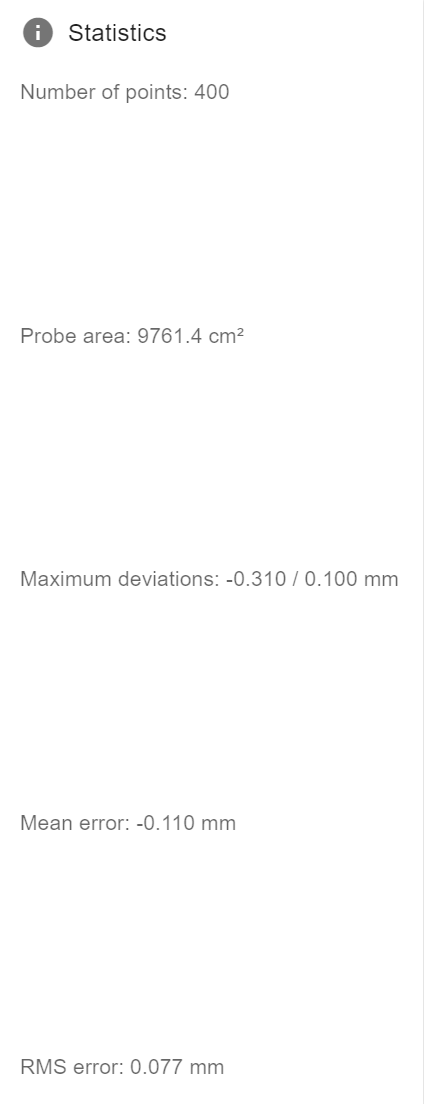

@bstump Post an image of your current heightmap with the values shown.

-

@phaedrux said in Verifying mesh levelling:

@bstump Post an image of your current heightmap with the values shown.

-

That center panel looks low given when this was generated. I am not sure the bed was fully heated or if the ceter was heated sufficiently.

-

With a bed like that I'd probably leave taper off entirely unless you're more concerned about wear and tear on the z axis. Otherwise try 50mm

Take a look at this to see if it might fit into your work flow.

https://forum.duet3d.com/topic/15302/cura-script-to-automatically-probe-only-printed-area

This way you could maximize the 440 points into the exact area you're printing on, with the downside of needing to probe before each print. Though if the area is smaller you could probably get away with fewer than the full 441.

Can you also post your config.g again? I can't seem to find it scrolling up. There are potentially improvements we can make to the probing settings.

-

@phaedrux said in Verifying mesh levelling:

@bstump Post an image of your current heightmap with the values shown.

I am wondering if the taper has some limits built in for how much or how little it can handle. Maybe given the overall bed size the variation is too much to deal with with one are it is apply a 0.00001mm taper adjustment and at another it needs a 0.01 per layer.

-

-

@fcwilt said in Verifying mesh levelling:

I don't use taper at all.

Frederick

We do jigs and fixtures and prototypes with this. Or that is the intention. given the flatness of the best not using taper could be an issue. But so is not adhering.

-

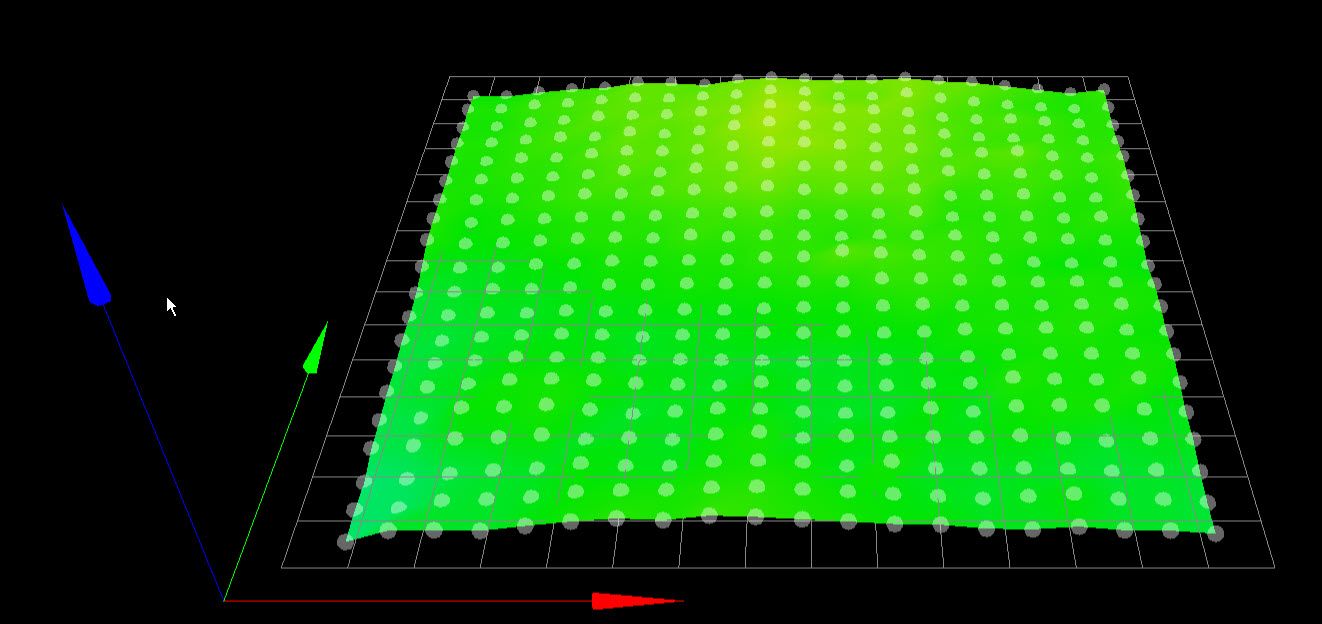

I use cast tool plate for the beds of my printers which from my supplier is spec'd to be flat within 0.4 mm but is usually much better.

I have found that bed adhesion is affected by many factors but these are what work for me:

- use the best cast tool plate you can find

- get the bed level within 0.005mm

- use 400 point mesh compensation

- use a first layer printing speed 10%-20% of the normal print speed

- turn off the part cooling fan for the first layer

Frederick

Here is the height map from my modified FT5 printer:

-

@fcwilt said in Verifying mesh levelling:

use the best cast tool plate you can find

1 square meter of cast tooling plate may be a bit expensive.