RRF 3.4 input shaping preview available

-

@dc42 I’m having some issues to collect the data with the version from July 31 using a Duet 3 6HC and Tool board V1.1

M955 P121.0 I25 Accelerometer 121:0 type LIS3DH with orientation 25 samples at 1344Hz with 10-bit resolutionI have been using these 2 macros with the previous versions without any issue

Macro: 03- Capture XM593 P"none" ; disable DAA ;M593 P"zvd" F46 G1 X200 Y200 Z50 ;G1 X150 G4 S2 M956 P121.0 S1000 A0 G4 P10 G1 X20 F20000 G1 X50 G4 S2 G1 X200 F20000 M400 M956 XY P121.0 S1000 A0Macro: 03- Capture Y

M593 P"none" ; disable DAA ;M593 P"zvd" F46 G1 X200 Y200 Z50 ;G1 X150 G4 S2 M956 P121.0 S1000 A0 G4 P10 G1 X20 F20000 G1 Y50 G4 S2 G1 Y200 F20000 M400 M956 P121.0 S1000 A0With the last version, the first macro run with no errors and no data are being records (I did click on the refresh button), then if I try to run the second, I have this error:

M98 P"0:/macros/Input shaping/03- Capture Y" Error: Accelerometer is already collecting dataM122

=== Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.4.0beta2-inputshaping (2021-07-31 22:02:01) running on Duet 3 MB6HC v1.01 or later (standalone mode) Board ID: 08DJM-956BA-NA3TJ-6J1FL-3S46N-998YS Used output buffers: 3 of 40 (19 max) === RTOS === Static ram: 151128 Dynamic ram: 93036 of which 256 recycled Never used RAM 106252, free system stack 200 words Tasks: NETWORK(ready,28.5%,236) ETHERNET(notifyWait,0.1%,167) HEAT(delaying,0.0%,326) Move(notifyWait,0.0%,352) CanReceiv(notifyWait,0.0%,798) CanSender(notifyWait,0.0%,373) CanClock(delaying,0.0%,340) TMC(notifyWait,7.8%,93) MAIN(running,63.4%,924) IDLE(ready,0.1%,29), total 100.0% Owned mutexes: === Platform === Last reset 00:01:32 ago, cause: software Last software reset at 2021-07-31 17:48, reason: User, GCodes spinning, available RAM 106252, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 130 MCU temperature: min 44.0, current 44.1, max 44.5 Supply voltage: min 24.1, current 24.1, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.0, current 12.1, max 12.3, under voltage events: 0 Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Driver 0: position 0, standstill, reads 56205, writes 15 timeouts 0, SG min/max 0/0 Driver 1: position 0, standstill, reads 56205, writes 15 timeouts 0, SG min/max 0/0 Driver 2: position 0, standstill, reads 56206, writes 14 timeouts 0, SG min/max 0/0 Driver 3: position 0, standstill, reads 56206, writes 14 timeouts 0, SG min/max 0/0 Driver 4: position 0, standstill, reads 56207, writes 14 timeouts 0, SG min/max 0/0 Driver 5: position 0, standstill, reads 56207, writes 14 timeouts 0, SG min/max 0/0 Date/time: 2021-07-31 17:49:38 Slowest loop: 4.15ms; fastest: 0.05ms === Storage === Free file entries: 10 SD card 0 detected, interface speed: 25.0MBytes/sec SD card longest read time 2.3ms, write time 0.0ms, max retries 0 === Move === DMs created 125, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === CAN === Messages queued 851, received 1130, lost 0, longest wait 2ms for reply type 6049, peak Tx sync delay 423, free buffers 49 (min 48), ts 462/461/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 2.79ms; fastest: 0.02ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions Telnet(0), 0 sessions HTTP sessions: 1 of 8 - Ethernet - State: active Error counts: 0 0 0 0 0 Socket states: 5 2 2 2 2 0 0 0M122 B121

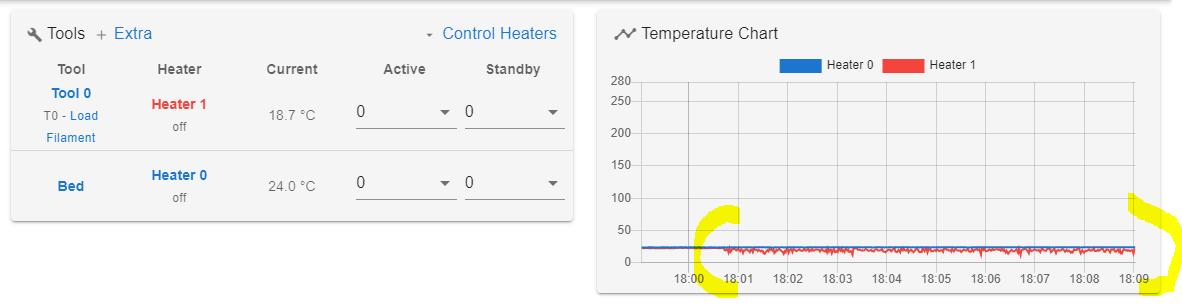

Diagnostics for board 121: Duet TOOL1LC firmware version 3.4beta1+ (2021-07-31 19:12:33) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) Never used RAM 2712, free system stack 2789 words Tasks: Move(notifyWait,0.0%,153) HEAT(delaying,0.2%,117) CanAsync(notifyWait,0.0%,65) CanRecv(notifyWait,0.0%,76) CanClock(notifyWait,0.0%,65) ACCEL(notifyWait,0.0%,61) TMC(notifyWait,2.8%,57) MAIN(running,92.0%,352) IDLE(ready,0.0%,27) AIN(delaying,4.9%,142), total 100.0% Last reset 00:02:07 ago, cause: software Last software reset data not available Driver 0: position 0, 655.0 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 1, ifcnt 62, reads 63964, writes 11, timeouts 0, DMA errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter 0/4, peak Rx sync delay 207, resyncs 0/0, no step interrupt scheduled VIN: 24.4V MCU temperature: min 39.1C, current 39.2C, max 39.6C Ticks since heat task active 233, ADC conversions started 127978, completed 127976, timed out 0, errs 0 Last sensors broadcast 0x00000002 found 1 238 ticks ago, loop time 0, Vref 43268 Vssa 369 CAN messages queued 1570, send timeouts 0, received 1172, lost 0, free buffers 37, min 37, error reg 110000 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer detected: yes, status: bb I2C bus errors 0, naks 0, other errors 0I have also noticed that the temperature sensor (Heater 1) is now acting in a strange way - I don't remember seeing that before.

-

I just noticed 2 things:

-

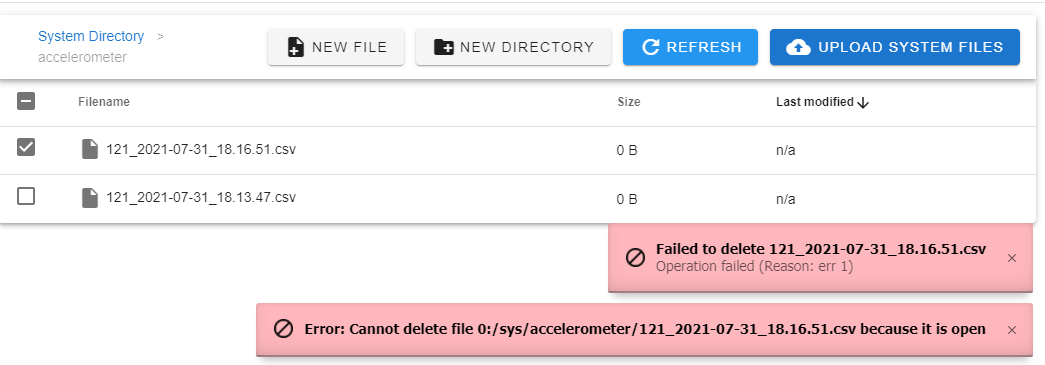

a file is created to collect the data but it is empty and also seems to stay open

I have to reboot the board and after I can delete it -

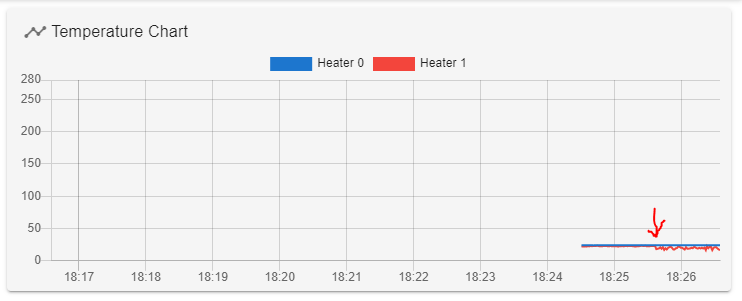

The temperature only start to act weirdly after I tried to collect the data from the accelerometer.

The arrow is when I ran the macro to collect data, it sounds directly related.

I hope these info are useful, let me know if you would like additional details.

Edit:

I did a little more testing and rolled back the firmwares to get back to a stable version, it seems the issue is with the Tool Board 1LC firmware, it seems to be working fine with this combo:- RepRapFirmware for Duet 3 MB6HC version 3.4.0beta2-inputshaping (2021-08-01 00:01:41) running on Duet 3 MB6HC v1.01 or later (standalone mode)

- Duet TOOL1LC firmware version 3.3 (2021-06-15 16:12:58)

-

-

@dc42 Sorry to always be the bearer of bad news but no real difference with this firmware from what I can tell, still hearing clunking noises and still extrusion issues and jagginess on the print with PA enabled and EI3 input shaping enabled. I will try and do a test with input shaping disabled soon.

UPDATE: started a print with input shaping disabled, and was getting the clunking, maybe even worse than with input shaping on. Disabled PA and things quieted back to normal. I then turned on input shaping back on (with PA disabled) and it still sounds normal, no clunking. so PA in general seems to be the cause of the clunking. I'll see if I'm still having extrusion blobs/zits with PA disabled but input shaping on.

UPDATE 2: still seeing the same extrusion blobs with PA off and input shaping (ei3) enabled.

stats below are from the print with both PA and input shaping enabled:

=== Move ===

DMs created 83, segments created 35, maxWait 39679ms, bed compensation in use: mesh, comp offset 0.000

=== MainDDARing ===

Scheduled moves 11545, completed moves 11545, hiccups 2744, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.0beta2-inputshaping (2021-08-01 00:01:15) running on Duet WiFi 1.02 or later + DueX5

-

@dc42 I also tested the new version and couldn't see any improvement.

The issue only happens when PA is on. As soon as PA is off, the extrusion is correct.

It's a problem with PA even without input shaping.=== Move === DMs created 83, segments created 42, maxWait 11789ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 3006, completed moves 3006, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 -

-

@dc42 said in RRF 3.4 input shaping preview available:

I have now fixed that and updated the binaries at https://www.dropbox.com/sh/ja08b7qdzsl8kjc/AAAwUbkN2XJvurq5CuQTgx5Wa?dl=0.

In my case, after installing the latest 3.4.0beta2-inputshaping (2021-08-01) - after starting the print DWC immediately reports the completed print - although the table is just warming up and printing has not even started yet. I cannot stop printing because only the - "print again" button is active - I have to click on emergency stop.

Below is the status screen -after printing has started

-

@dc42 my experience is similar - I use pa of 0.8, and this gives clunking and poor finish, with and without input shaping, and around 6000 hiccups per 18000 moves for both. Reducing pa to 0.2, still without shaping, gave a much better result, but still 446 hiccups. Clunking still noticeable, particularly on the first half layer of solid infill - the second half of the layer where the line length is decreasing is much smoother

-

@adrian52 I'm printing 2 cubes, one with stable and one with the beta. I'm mid second print and seems that same PA value (0.04) gives different results with the beta... i'll try to post detailed photos of the outcome once it's finished.

I hear less noise from the extruder than latest beta, still there is some there. More noticeable at higher printing speed.

3.3 Stable:

3.4 Beta:

Unluckily i have to dry the filament buut it's the only glossy filament that i have atm and is easier to shot to seeartifacts. As you can see there is something wrong on the edges of beta print. Seems that more PA is needed than 3.3.

Printed with the same g-code with the same settings.

M122 B1 report:

M122 B1 === Diagnostics === RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.0beta2-inputshaping (2021-08-01 00:01:15) running on Duet WiFi 1.02 or later + DueX5 Board ID: 0JD0M-9P61A-J8PS8-6JTD2-3SJ6R-9USUU Used output buffers: 3 of 24 (24 max) === RTOS === Static ram: 23932 Dynamic ram: 76624 of which 12 recycled Never used RAM 7456, free system stack 106 words Tasks: NETWORK(ready,14.8%,217) HEAT(delaying,0.0%,326) Move(notifyWait,0.0%,285) DUEX(notifyWait,0.0%,24) MAIN(running,85.2%,441) IDLE(ready,0.0%,29), total 100.0% Owned mutexes: WiFi(NETWORK) HTTP(MAIN) === Platform === Last reset 00:47:14 ago, cause: software Last software reset at 2021-07-30 17:52, reason: User, GCodes spinning, available RAM 11316, slot 2 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a Error status: 0x0c Aux0 errors 0,0,0 Step timer max interval 0 MCU temperature: min 41.5, current 43.0, max 43.5 Supply voltage: min 23.7, current 23.9, max 24.1, under voltage events: 0, over voltage events: 0, power good: yes Heap OK, handles allocated/used 99/0, heap memory allocated/used/recyclable 2048/890/890, gc cycles 0 Driver 0: position 28800, standstill, SG min/max not available Driver 1: position -27200, standstill, SG min/max not available Driver 2: position 120000, standstill, SG min/max not available Driver 3: position 0, standstill, SG min/max not available Driver 4: position 0, standstill, SG min/max not available Driver 5: position 0, standstill, SG min/max not available Driver 6: position 0, standstill, SG min/max not available Driver 7: position 0, standstill, SG min/max not available Driver 8: position 0, standstill, SG min/max not available Driver 9: position 0, standstill, SG min/max not available Driver 10: position 0 Driver 11: position 0 Date/time: 2021-08-01 13:01:42 Cache data hit count 4294967295 Slowest loop: 6.30ms; fastest: 0.17ms I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0 === Storage === Free file entries: 10 SD card 0 detected, interface speed: 20.0MBytes/sec SD card longest read time 0.6ms, write time 0.0ms, max retries 0 === Move === DMs created 83, segments created 50, maxWait 0ms, bed compensation in use: mesh, comp offset 0.000 === MainDDARing === Scheduled moves 59750, completed moves 59750, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP is ready with "M122 B1" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 Daemon is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty === DueX === Read count 0, 0.00 reads/min === Network === Slowest loop: 202.82ms; fastest: 0.10ms Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions HTTP sessions: 1 of 8 - WiFi - Network state is active WiFi module is connected to access point Failed messages: pending 0, notready 0, noresp 1 WiFi firmware version 1.24 WiFi MAC address 48:3f:da:79:65:eb WiFi Vcc 3.34, reset reason Power up WiFi flash size 4194304, free heap 27144 WiFi IP address 192.168.1.230 WiFi signal strength -21dBm, mode none, reconnections 0, sleep mode modem Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0 -

I've identified and fixed some issues affecting extrusion with pressure advannce, and updated the binaries at https://www.dropbox.com/sh/ja08b7qdzsl8kjc/AAAwUbkN2XJvurq5CuQTgx5Wa?dl=0 again.

-

@dc42 seems like same results on this firmware for me. Clunking sounds, and extrusion issues/jagginess on a calibration cube print with PA and input shaping (ei2). my PA is at 0.12.

sorry in previous posts I've been putting my input shaping as ei3, I meant ei2. It's been ei2 not ei3.

=== Move ===

DMs created 83, segments created 35, maxWait 23643ms, bed compensation in use: mesh, comp offset 0.000

=== MainDDARing ===

Scheduled moves 11545, completed moves 11545, hiccups 3024, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.0beta2-inputshaping (2021-08-01 21:19:05) running on Duet WiFi 1.02 or later + DueX5

seems like the number of hiccups actually went up with this firmware.

-

@dc42 said in RRF 3.4 input shaping preview available:

I've identified and fixed some issues affecting extrusion with pressure advannce, and updated the binaries at https://www.dropbox.com/sh/ja08b7qdzsl8kjc/AAAwUbkN2XJvurq5CuQTgx5Wa?dl=0 again.

Same problem as with previous binaries - after starting a print, the status immediately shows that the print is 100% complete - when I click emergency stop, DWC hangs up and I have to physically cut power to reset the printer

-

@cadetc said in RRF 3.4 input shaping preview available:

@dc42 said in RRF 3.4 input shaping preview available:

I've identified and fixed some issues affecting extrusion with pressure advannce, and updated the binaries at https://www.dropbox.com/sh/ja08b7qdzsl8kjc/AAAwUbkN2XJvurq5CuQTgx5Wa?dl=0 again.

Same problem as with previous binaries - after starting a print, the status immediately shows that the print is 100% complete - when I click emergency stop, DWC hangs up and I have to physically cut power to reset the printer

Did you check for error messages in the console?

-

@skrotz said in RRF 3.4 input shaping preview available:

@dc42 seems like same results on this firmware for me. Clunking sounds, and extrusion issues/jagginess on a calibration cube print with PA and input shaping (ei2). my PA is at 0.12.

Please can you try a print with PA enabled but input shaping disabled, and let me know if it behaves any differently from RRF 3.3.

-

@dc42 said in RRF 3.4 input shaping preview available:

@cadetc said in RRF 3.4 input shaping preview available:

@dc42 said in RRF 3.4 input shaping preview available:

I've identified and fixed some issues affecting extrusion with pressure advannce, and updated the binaries at https://www.dropbox.com/sh/ja08b7qdzsl8kjc/AAAwUbkN2XJvurq5CuQTgx5Wa?dl=0 again.

Same problem as with previous binaries - after starting a print, the status immediately shows that the print is 100% complete - when I click emergency stop, DWC hangs up and I have to physically cut power to reset the printer

Did you check for error messages in the console?

no error codes

-

@dc42 said in RRF 3.4 input shaping preview available:

@cadetc said in RRF 3.4 input shaping preview available:

@dc42 said in RRF 3.4 input shaping preview available:

I've identified and fixed some issues affecting extrusion with pressure advannce, and updated the binaries at https://www.dropbox.com/sh/ja08b7qdzsl8kjc/AAAwUbkN2XJvurq5CuQTgx5Wa?dl=0 again.

Same problem as with previous binaries - after starting a print, the status immediately shows that the print is 100% complete - when I click emergency stop, DWC hangs up and I have to physically cut power to reset the printer

Did you check for error messages in the console?

no error codes -All in all, the print sequence is OK, first the table heats up, then noozle and the print starts - even though the status from the very beginning shows the print as 100% complete - I think there is a bug with the layer count so DWC indicates the print as 100% complete

-

When I made a downgrade to an earlier beta then it is OK - the problem appeared in the beta version released today

-

@dc42 Yes with input shaping disabled but PA enabled I am getting the clunking noises, different from RRF 3.3.

-

@cadetc said in RRF 3.4 input shaping preview available:

@dc42 said in RRF 3.4 input shaping preview available:

@cadetc said in RRF 3.4 input shaping preview available:

@dc42 said in RRF 3.4 input shaping preview available:

I've identified and fixed some issues affecting extrusion with pressure advannce, and updated the binaries at https://www.dropbox.com/sh/ja08b7qdzsl8kjc/AAAwUbkN2XJvurq5CuQTgx5Wa?dl=0 again.

Same problem as with previous binaries - after starting a print, the status immediately shows that the print is 100% complete - when I click emergency stop, DWC hangs up and I have to physically cut power to reset the printer

Did you check for error messages in the console?

no error codes -All in all, the print sequence is OK, first the table heats up, then noozle and the print starts - even though the status from the very beginning shows the print as 100% complete - I think there is a bug with the layer count so DWC indicates the print as 100% complete

Please provide the print file and your config.g file.

-

@cadetc RRF 3.4-b2pre isn't compatible with the DSF version from the unstable package feed. We'll update the package feed as soon as the remaining issues with IS/PA are confirmed to be fixed.

-

@dc42 said in RRF 3.4 input shaping preview available:

Please provide the print file and your config.g file.

Below my config.g and print file

tension, cover, bltouch_32m.g

config (5).g; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat Apr 17 2021 20:39:32 GMT+0200 (czas środkowoeuropejski letni) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name M669 K1 ; select CoreXY mode G4 S5 ;wait for expansion boards to start ; Drives M569 P0.5 S0 ; x axis physical drive 0.5 goes forward M569 P0.4 S0 ; y axis physical drive 0.4 goes forward M569 P0.2 S1 ; Fron right bed physical drive 0.2 goes forwards M569 P121.0 S1 ;extruder physical drive 121.0 goes forwards M569 P0.0 S1 ; Front left bed physical drive 0.0 goes forwards M569 P0.1 S1 ; Rear bed physical drive 0.1 goes forwards M584 X0.5 Y0.4 Z0.0:0.1:0.2 E121.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z800.00 E409.00 ; set steps per mm M566 X1200.00 Y1200.00 Z30.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y30000.00 Z1800.00 E3000.00 ; set maximum speeds (mm/min) M201 X6000.00 Y6000.00 Z200.00 E2000.00 ; set accelerations (mm/s^2) M906 X2000 Y2000 Z1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M671 X-27.4:147.5:322.4 Y-4.5:324.5:-4.5 S20 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X290 Y280 Z290 S0 ; set axis maxima M955 P121.0 I41 ; Endstops M574 X2 S1 P"121.io1.in" ; configure active-high endstop for high end on X via pin 121.io1.in M574 Y1 S1 P"io1.in" ; configure active-high endstop for low end on Y via pin io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"^121.io0.in" H15 F240 T9000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-1 Y-32 Z2.50 ; set Z probe trigger value, offset and trigger height M557 X10:290 Y3:290 S30 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S130 ; set temperature limit for heater 0 to 130C M308 S1 P"121.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C ; Fans M950 F0 C"out7" Q25000 ; create fan 0 on pin out7 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"121.out2" Q500 ; create fan 1 on pin 121.out2 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C T0 ; select first hot end ; Miscellaneous M572 D0 S0.022 ;enable pressure advance value of 0.022 M575 P1 S1 B57600 ; enable support for PanelDue M501 ; load saved parameters from non-volatile memory M911 S22 R23.5 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power lossI have no problems with the July 28 beta bin

Duet3Firmware_MB6HC-28-07.binPrint status problem started with the August 1 beta bin

Duet3Firmware_MB6HC-1-08.binBut as chrishamm said

RRF 3.4-b2pre isn't compatible with the DSF version from the unstable package feed. We'll update the package feed as soon as the remaining issues with IS/PA are confirmed to be fixed.

Problem lays with incompatibilie DSF - only surprised me why works with ver. 28-07 but not with ver. 1-08