Tool Board Heater Tuning Leading To Faults

-

@kevinmar please run M307 H1 with no other parameters, to check that it really is using the parameters that you found from tuning.

-

@diy-o-sphere Yes

-

@dc42 Confirmed, it is using the parameters that I found from tuning

-

@kevinmar said in Tool Board Heater Tuning Leading To Faults:

The Hemera's have an overpowered part cooling fan, so I'm tuning using M303 T0 A30 F.40 S220

The tuning runs fine, but when I paste the parameters into config.g, the resulting heater activation inevitably results in a fault before the tool reaches 120C, usually around 70-100C

Is the ambient temp really 30?

And what fault are you getting?

Frederick

-

@kevinmar

Do you still have old parameters in the config-override.g?

But after you have checked the heater in the console it should actually fit. -

@fcwilt Ambient is 26-30C

I am not getting a fault readout in the console -

@diy-o-sphere No, old parameters are overwritten when a new set is generated and saved using M500

-

@kevinmar said in Tool Board Heater Tuning Leading To Faults:

@fcwilt Ambient is 26-30C

Wow. I gather it is hot were you live and you have no air conditioning?

I am not getting a fault readout in the console

You posted this where you said there was a fault.

The tuning runs fine, but when I paste the parameters into config.g, the resulting heater activation inevitably results in a fault before the tool reaches 120C, usually around 70-100C

-

I think it's faulting way too liberally. My heater and PT1000 are working, it's not like I'm experiencing thermal runaway.

Is there a way to change the sensitivity of the faults? -

@kevinmar said in Tool Board Heater Tuning Leading To Faults:

I think it's faulting way too liberally. My heater and PT1000 are working, it's not like I'm experiencing thermal runaway.

Is there a way to change the sensitivity of the faults?What fault are you getting?

-

@fcwilt Well, true ambient is about 24C, but the PT1000's always read about 27C as ambient.

The heater faults, but there is no readout in the console.

-

@kevinmar said in Tool Board Heater Tuning Leading To Faults:

@fcwilt Well, true ambient is about 24C, but the PT1000's always read about 27C as ambient.

The heater faults, but there is no readout in the console.

In what way does the heater fault?

-

@fcwilt I wish I knew!

-

@kevinmar said in Tool Board Heater Tuning Leading To Faults:

@fcwilt I wish I knew!

What is happening that is evidence of a fault?

Frederick

-

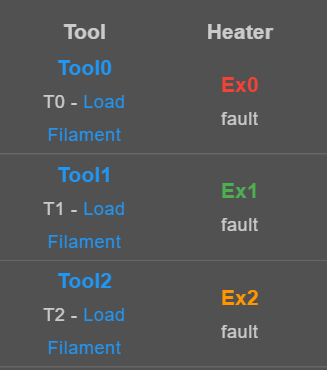

-

@kevinmar

Please post the config.g -

-

@kevinmar said in Tool Board Heater Tuning Leading To Faults:

OK that helps.

All all three heaters actually active at the same time?

Do they all fault at the same time?

Can you take a screen shot of the temp graph showing the heaters as they heat up and then fault?

Frederick

-

@kevinmar

Your sensor settings a looking wrong...Here is an example of mine

M308 S1 P"temp1" Y"pt1000" R2200 ; configure sensor 1 as PT1000 on pin temp1 -

Please get in the habit of copy-and-pasting your files using the </> tag.

M550 P"ToolChanger" ; Set machine name M111 S0 ; Debug off M929 P"eventlog.txt" S1 ; Start logging to file eventlog.txt M555 P1 ; Set RepRap output G21 ; Set dimensions to millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M669 K1 ; CoreXY mode G4 S1 ; Wait for expansion boards to start M569 P0.0 S1 D2 ; Drive 0 direction | X M569 P0.1 S1 D2 ; Drive 1 direction | Y M569 P0.2 S1 D2 ; Drive 2 direction | Z M569 P0.4 S0 D2 ; Drive 3 direction | C M569 P0.5 S0 D2 ; Drive 5 direction | A M569 P20.0 S0 D2 ; Drive 6 direction | T0 M569 P21.0 S0 D2 ; Drive 7 direction | T1 M569 P22.0 S0 D2 ; Drive 8 direction | T2 M569 P23.0 S0 D2 ; Drive 9 direction | T3 M584 X0 Y1 Z2 E20.0:21.0:22.0:23.0 C4 A5 ; Axis to driver mapping ; Set axis software limits and min/max switch-triggering positions. M208 X-35:320 Y-49:240 Z0:300 C-45:360 A0:55 M350 X16 Y16 Z16 E16:16:16:16 A16 I1 ; Configure microstepping with interpolation M350 C16 I10 ; Configure microstepping without interpolation M906 X1800 Y1800 Z1000 I30 ; Set motor currents (mA) and idle percent M906 E1500:1500:1500:1500 C500 I10 ; Set motor currents (mA) and idle percent A400 M203 X36000 Y36000 Z1200 C5000 E6000:6000:6000:6000 A6000 ;Max speeds (mm/min) M201 X6000 Y6000 Z400 C600 E6000:6000:6000:6000 A1200 ; Max Accelerations (mm/s^2) M566 X400 Y400 Z60 C6 E60:60:60:60 A360 ; Max jerk (mm/min) M92 X100 Y100 Z800 E386:386:386:386 C91.022 A360 ; Steps/mm M574 X1 Y1 S3 ; X / Y Endstop M574 Z1 S1 P"nil" ; Z Endstop M574 C0 ; Z / C No Endstop M558 P5 C"!io0.in" H5 A5 T6000 S0.01 K0 G31 P200 X0 Y0 Z0 M557 X10:290 Y20:180 S40 ; Define mesh grid M915 X Y S3 F0 H400 R2 ; X / Y Axes M915 A S5 F0 H200 R2 ; A Stall Detection ; Temperature sensors M308 S0 P"0.temp0" Y"thermistor" T100000 B4138 C0 A"Bed" M308 S1 P"20.temp0" Y"thermistor" T100000 B4725 C7.06e-8 A"Ex0" M308 S2 P"21.temp0" Y"pt1000" T100000 B4725 C7.06e-8 A"Ex1" M308 S3 P"22.temp0" Y"pt1000" T100000 B4725 C7.06e-8 A"Ex2" M308 S4 P"23.temp0" Y"pt1000" T100000 B4725 C7.06e-8 A"Ex3" ; Heaters M950 H0 C"0.out1" T0 ; Bed M140 H0 ; Bed M950 H1 C"20.out0" T1 ; Heater for extruder out tool 0 M950 H2 C"21.out0" T2 ; Heater for extruder out tool 1 M950 H3 C"22.out0" T3 ; Heater for extruder out tool 2 M950 H4 C"23.out0" T4 ; Heater for extruder out tool 3 ; Heater PID Tuning M307 H0 R1.641 C353.300:353.300 D2.50 S1.00 V24.0 B0 M307 H1 R1.590 C336.700:89.600 D5.00 S1.00 V23.8 B0 M307 H2 R2.135 C314.200:86.000 D6.20 S1.00 V24.3 B0 M307 H3 R2.023 C364.200:86.200 D5.70 S1.00 V23.7 B0 M307 H4 R1.900 C383.000:383.000 D7.50 S1.00 V23.8 B0 ;M307 H1 A849.7 C225.4 D5.9 S1.00 V24.2 B0 ; From Railcore with similar setup running V2.xx ; Max Temps M143 H0 S225 M143 H1 S300 M143 H2 S300 M143 H3 S300 M143 H4 S300 ; Fans for hot end cooling M950 F10 C"20.out2" M106 P10 S255 H1 T70 M950 F11 C"21.out2" M106 P11 S255 H2 T70 M950 F12 C"22.out2" M106 P12 S255 H3 T70 M950 F13 C"23.out2" M106 P13 S255 H4 T70 ; Fans for part cooling M950 F0 C"20.out1" M950 F1 C"21.out1" M950 F2 C"22.out1" M950 F3 C"23.out1" M950 F7 C"^0.out9" Q600 ;Wipe Servo M106 P7 C"Wipe" ;Wipe Servo M302 S185 R185 M404 N1.75 D0.4 ; Tool definitions M563 P0 S"Tool0" D0 H1 F0 G10 P0 S220 R205 M563 P1 S"Tool1" D1 H2 F1 G10 P1 S220 R205 M563 P2 S"Tool2" D2 H3 F2 G10 P2 S220 R205 M563 P3 S"Tool3" D3 H4 F3 G10 P3 S220 R205 G29 S2 M98 P"/sys/Toffsets.g" ; Set tool offsets from the bed T-1 M501 ; Load config-override.g