How to make Prusa Slicer work

-

@gloomyandy said in How to make Prusa Slicer work:

@the_dragonlord How did you tune your extruder steps/mm set in config.g? If it involved something that used your slicer you may have in effect tuned for that. What value do you have set for steps/mm in your config.g file and what extruder are you using?

415 step/mm, original bondtech BMG

-

@the_dragonlord Assuming that has a standard 1.8 degree stepper (does it?), that sounds fine.

-

@gloomyandy said in How to make Prusa Slicer work:

@the_dragonlord Assuming that has a standard 1.8 degree stepper (does it?), that sounds fine.

it sound because it is fine

with other slicers I have no problems

with other slicers I have no problems -

Is the first layer height the same? Same width and flow rate?

-

@the_dragonlord I've used PS for years with issues so am slightly perplexed by your issue!

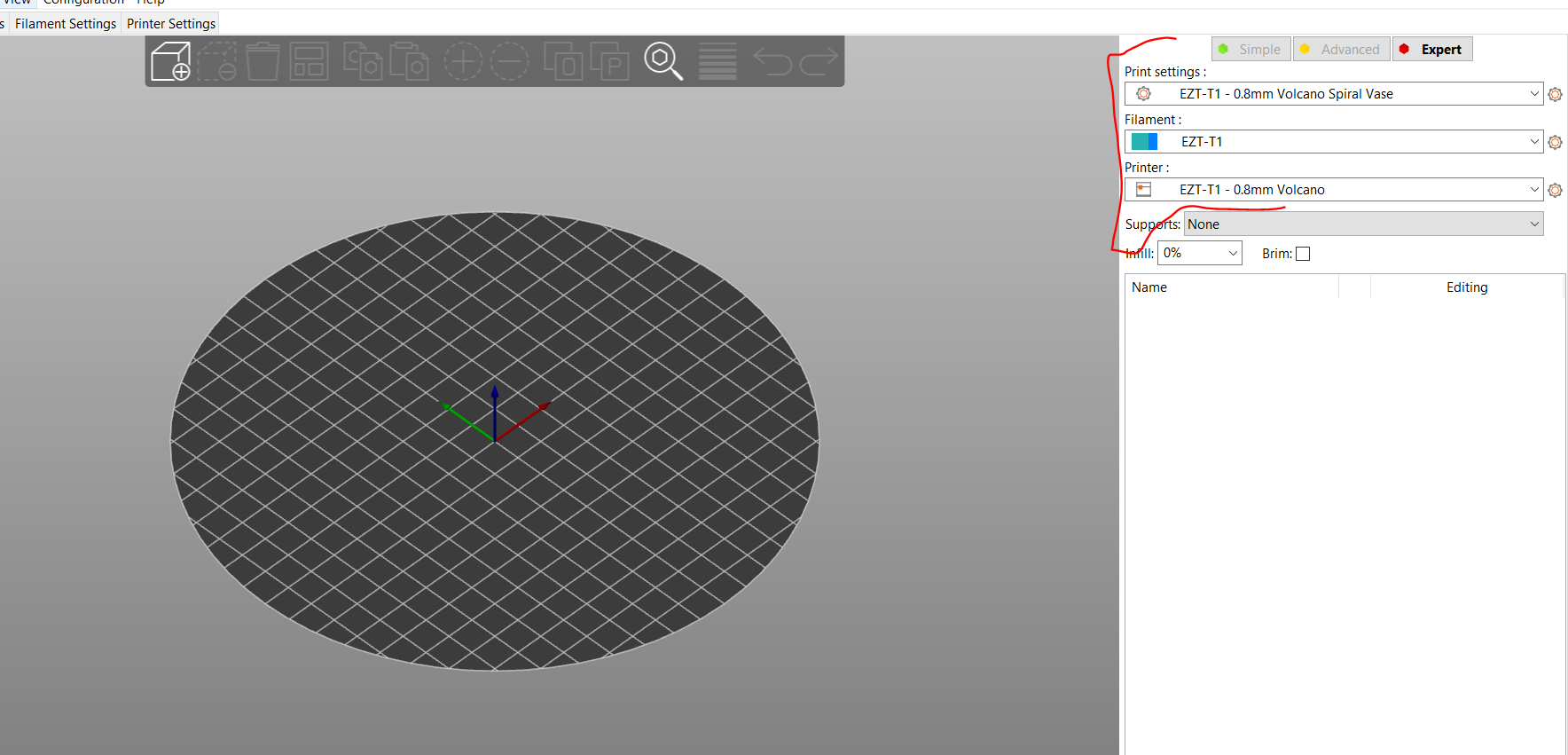

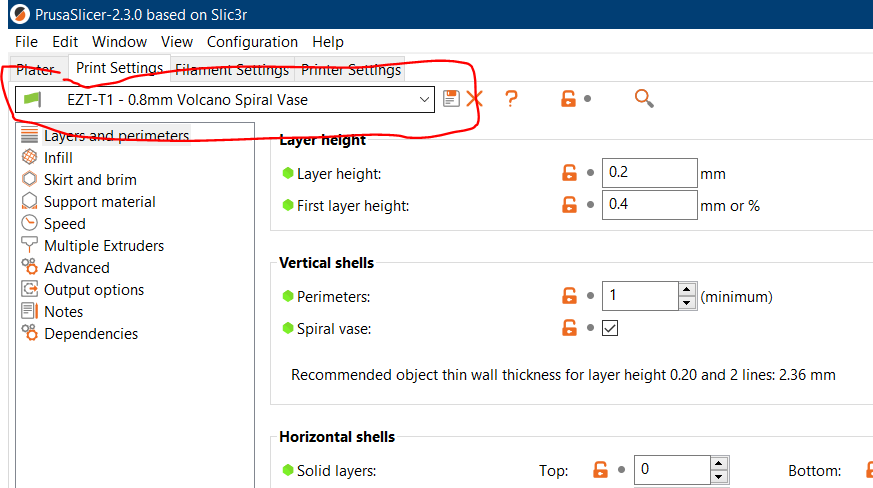

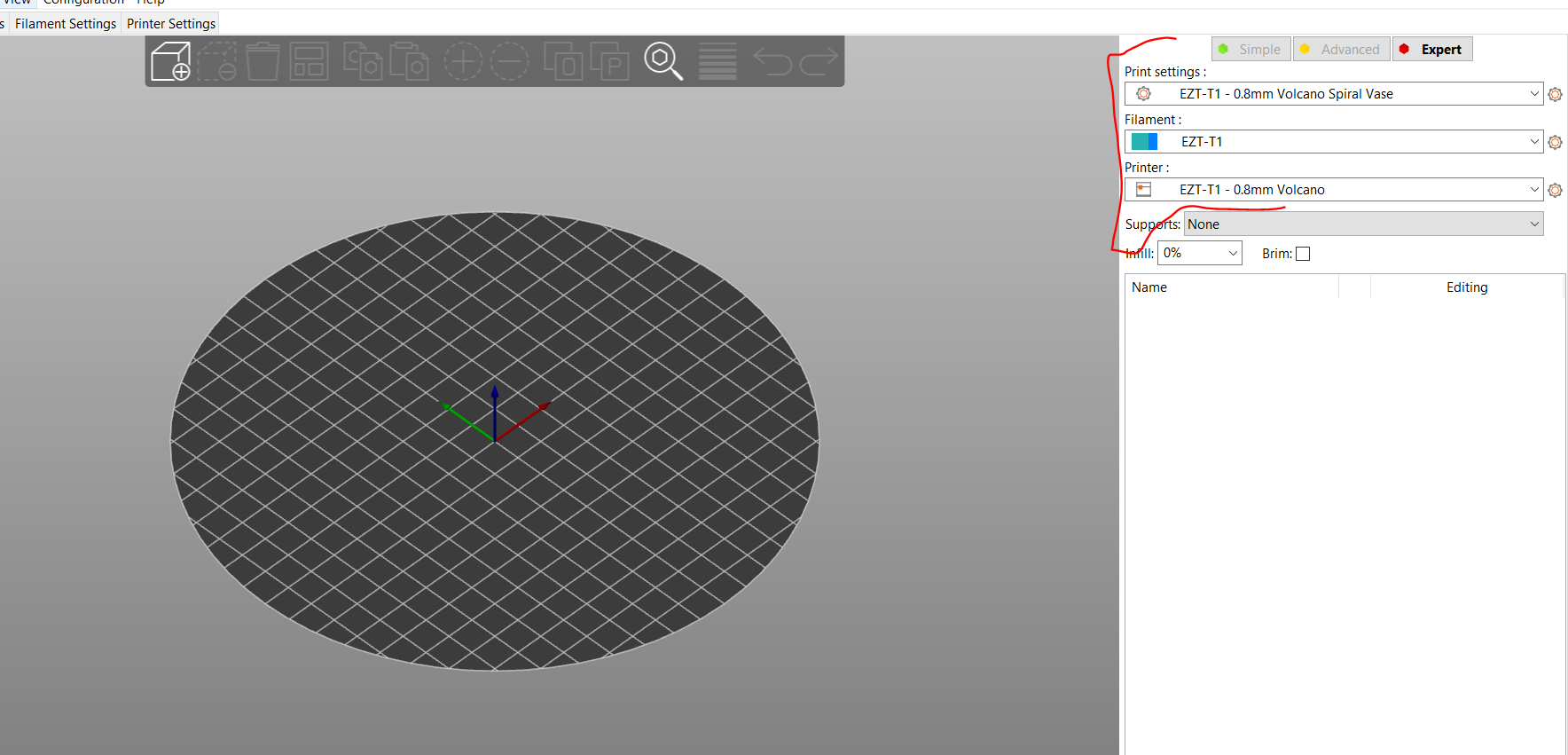

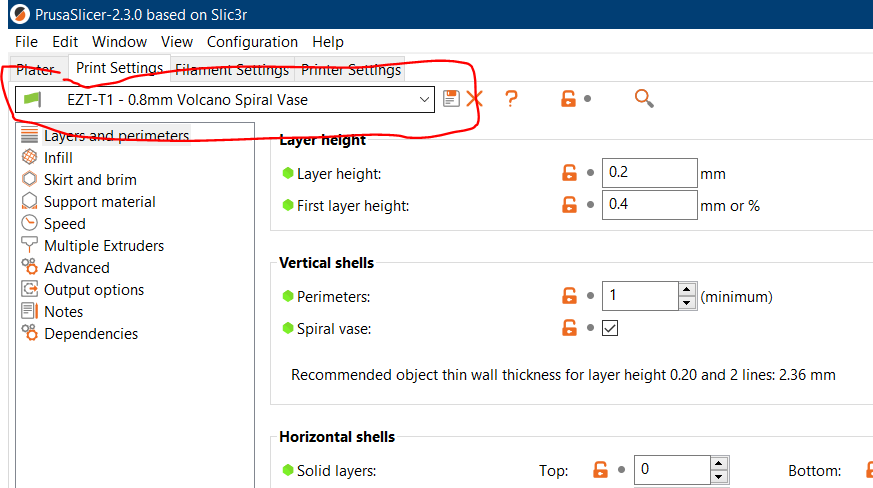

One thought - are the filament/printer/print profiles that you're editing the ones that PS is using to slice the file? I.E. Do these:

Match these:

Could simply be that you're actualy slicing with one of the default 2.85mm profiles?

Failing that, if you can export your config from PS (File, Export, Export config), post it here and I can try it on mine to see what's up. Might need to rename the filetype to .txt to upload it to the forum

-

@phaedrux said in How to make Prusa Slicer work:

Is the first layer height the same? Same width and flow rate?

yes

-

@engikeneer said in How to make Prusa Slicer work:

@the_dragonlord I've used PS for years with issues so am slightly perplexed by your issue!

One thought - are the filament/printer/print profiles that you're editing the ones that PS is using to slice the file? I.E. Do these:

Match these:

Could simply be that you're actualy slicing with one of the default 2.85mm profiles?

Failing that, if you can export your config from PS (File, Export, Export config), post it here and I can try it on mine to see what's up. Might need to rename the filetype to .txt to upload it to the forum

no, it's not my case, the profiles, unfortunately, are correct. Here's my config fileconfig.ini.txt

Thanks!

-

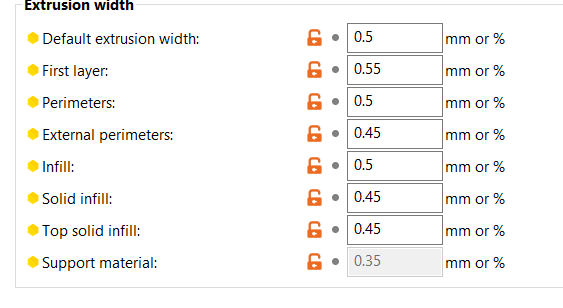

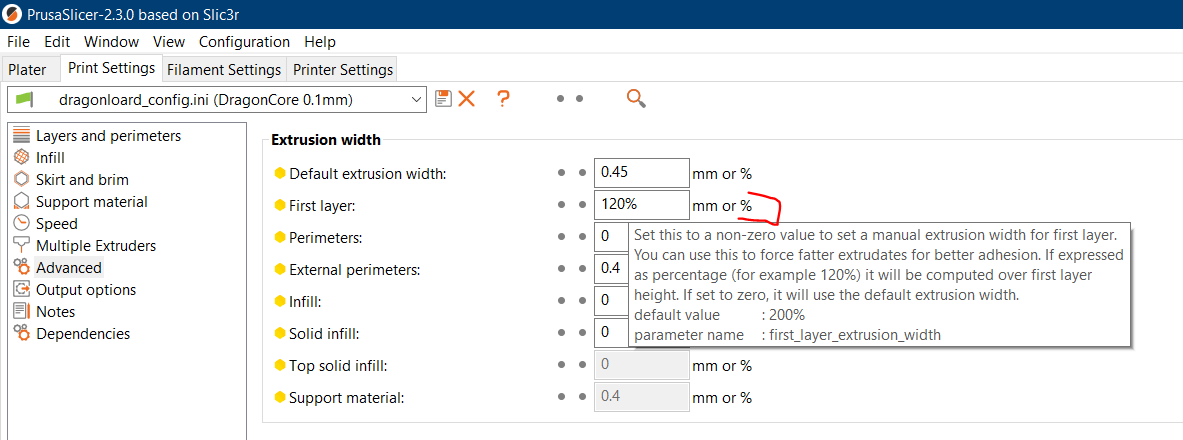

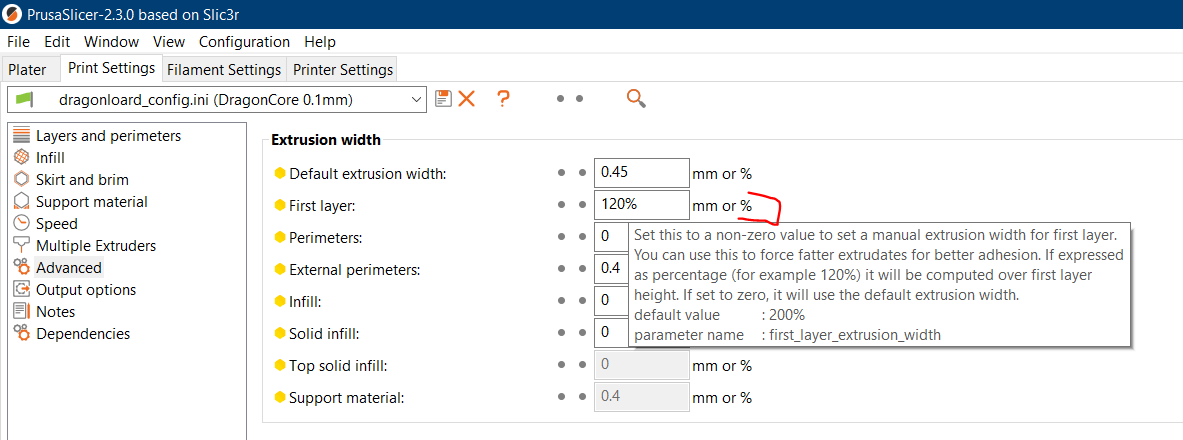

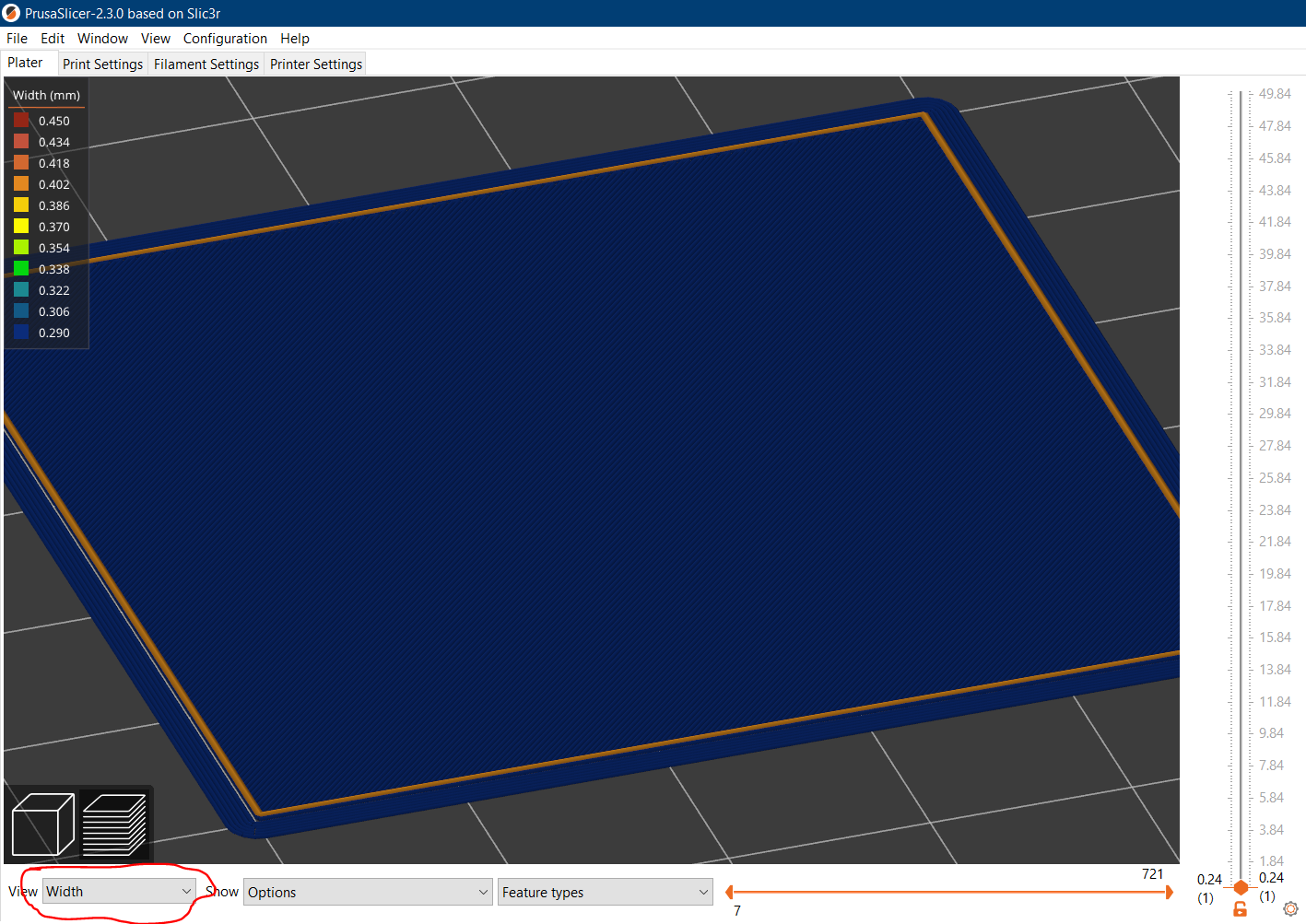

@the_dragonlord I think I've found some of your issue. Your first layer extrusion width is set to 120%, so over a 0.24mm first layer height, you only get 0.288mm width lines for your first layer. Personally, I set all these as widths in mm so I know what I'm getting even if I change the layer height.

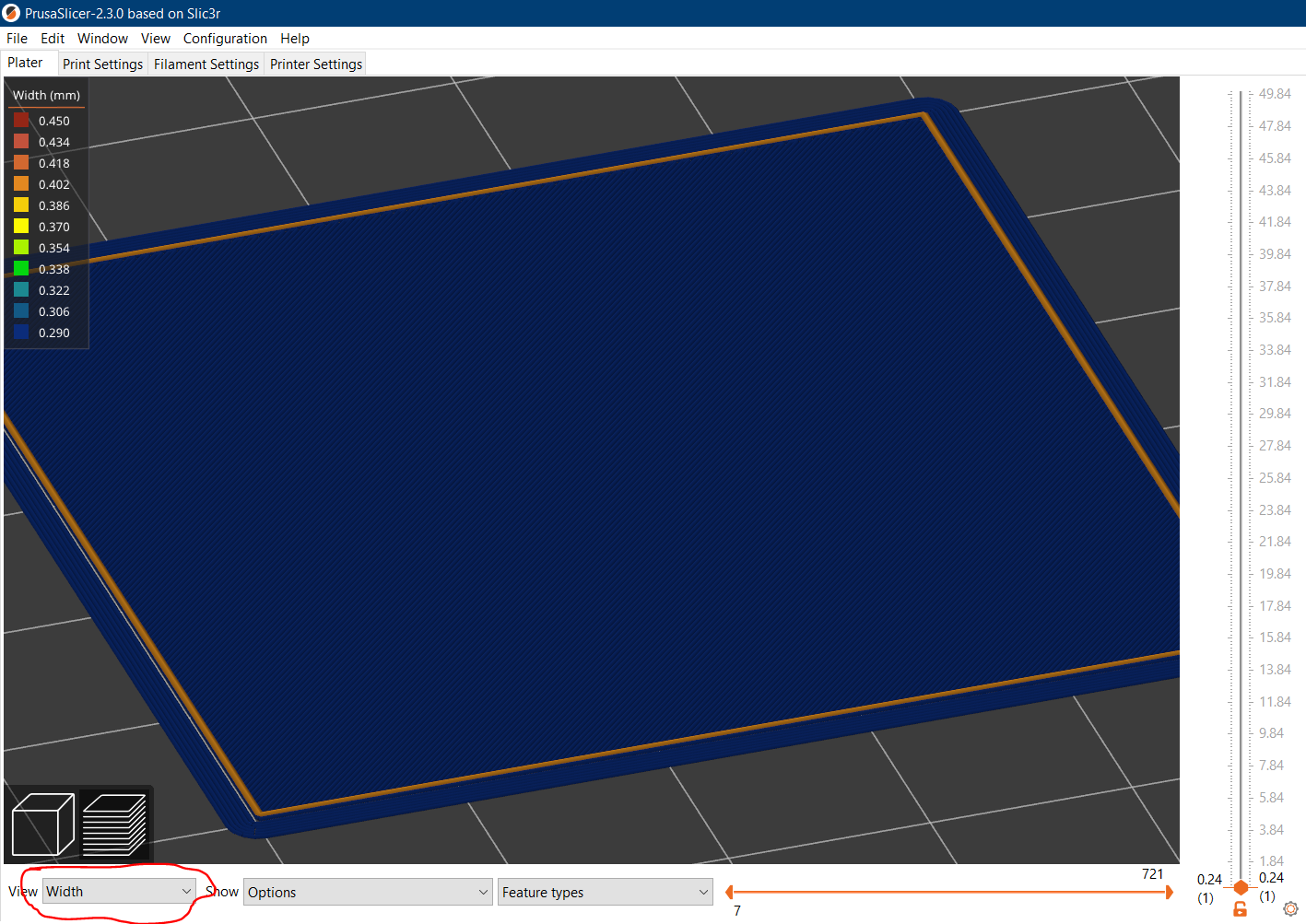

You can see this if you look at the sliced line widths on the plater. Looks like the brim and infil are affected, but the external perimeter is slicing at 0.4mm which you specified.

The other thing I noticed is that you are using absolute extrusion. General advice is to use relative extrusion because you may lose accuracy in long prints. Note that you've got M92 in your custom start code there too!

-

@engikeneer said in How to make Prusa Slicer work:

@the_dragonlord I think I've found some of your issue. Your first layer extrusion width is set to 120%, so over a 0.24mm first layer height, you only get 0.288mm width lines for your first layer. Personally, I set all these as widths in mm so I know what I'm getting even if I change the layer height.

You can see this if you look at the sliced line widths on the plater. Looks like the brim and infil are affected, but the external perimeter is slicing at 0.4mm which you specified.

The other thing I noticed is that you are using absolute extrusion. General advice is to use relative extrusion because you may lose accuracy in long prints. Note that you've got M92 in your custom start code there too!

excellent, thanks! i'll try your suggestions when I'll return home! what is your setting for the first layer extrusion width?

-

@engikeneer said in How to make Prusa Slicer work:

The other thing I noticed is that you are using absolute extrusion. General advice is to use relative extrusion because you may lose accuracy in long prints. Note that you've got M92 in your custom start code there too!

I thought that, and I would have sworn that's what at least one of the files extracts showed the first time I looked at them, but it's not what they show the second time I looked (and now). This is clearly not absolute extrusion:

;LAYER_CHANGE ;Z:0.44 ;HEIGHT:0.2 M98 P"Print_gcodes/pressure_advance_at_layer_change.g" G1 Z0.440 F7200.000 G10 S205 ; set temperature G1 X160.200 Y169.800 ;TYPE:External perimeter ;WIDTH:0.4 G1 F900.000 G1 X160.200 Y160.200 E0.28504 G1 X169.800 Y160.200 E0.28504 M73 P15 R2 G1 X169.800 Y169.800 E0.28504 G1 X160.260 Y169.800 E0.28325 G1 E-3.00000 F2400.000otherwise there's no extrusion on two of those sides, and retraction on the fourth.

So now I'm wondering if the forum is occasionally showing a differnet file to reasders!

-

@the_dragonlord I think 0.45mm for a 0.35mm nozzle, but I'm not 100% sure as I'm out today. Typically I'd do nozzle width +30-40% for first layer but I've never really played too much attention to it tbh...

Also @achrn makes a good point. In your first post you had relative extrusion selected but had an M82 in you custom start code which may have overridden things and caused your issue.

Edit: back home now and here are the setting I used to use for my 0.4mm nozzle (though I've been using a 0.35mm for a while now). They work okay for me, but not done any calibration etc - main thing is that the support material is less than nozzle dia so that it is weaker, all the others are larger