Smart Effector V3 an plastic nut

-

Where did you get the adapter? I have a Dragon hotend, but need an adapter.

-

@gurusmi i Had Problems with printed adapters... Even Out of Nylon CF. In the end i Machined one.

-

@velvia

I got a design from Thingiverse: https://www.thingiverse.com/thing:4818787 -

@PCR

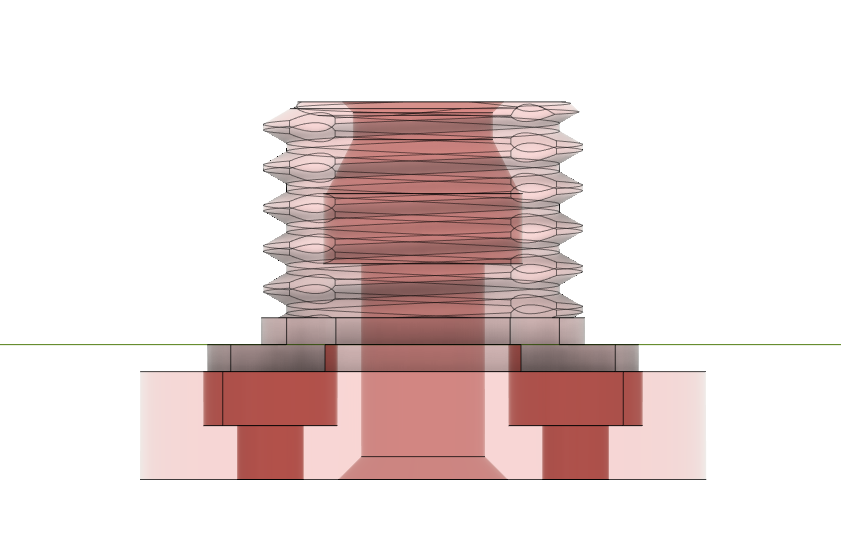

Also at my side. I printed it in NiceABS. A highly modified ABS by 3D Jake. The new tested Effector did not work that good especially when the nozzle is used as a z-Probe. The used filament seems to be much softer, than the Alloy used at the threaded heatsink. I used originally that design for the effector: https://www.thingiverse.com/thing:4603940 and changed it a bit. The holes for the screws are designed really fragile. I enlarged the material to a diameter of 11mm and everything worked out fine. I use for all three fans SuOns at 24v.A couple of weeks ago i changed from building up the printer to optimizing it. I got a quite good working effector with sliders utilizing a hell of original parts. And that i did want to simplify a bit.

-

@pcr CF Nylon is not good for parts that need to withstand heat. CNC Kitchen did a video on it: https://www.youtube.com/watch?v=4VSu_gG-nlk&t=364s

I'll try to print in CF-ABS or CF-PC. Tried to print in regular ABS and PC, but the threads don't print well, even with 0.05 layer height. Maybe 0.25 with CF filaments will work better? I don't have a resin printer to print ultra high detail parts.

Would love to have a machined part instead of 3D printed plastic.

-

@gurusmi Do you have the step files for this? I cannot get it to fit. The M3 screws are misaligned, and if I scale up the model, then the nylon nut won't fint. How is the bowden tube fastened?

-

- It isn't my thing. So i do not have any more stuff like you.

- There aren't M3 screws. There are holes for M2. They did fit very well for my dragonfly.

- For the Bowden i had a M6 Holder added to a original Capricorn Set. The thread i did cut myself.

- The nut wich did hold my full construction has been a M12 metal nut.

-

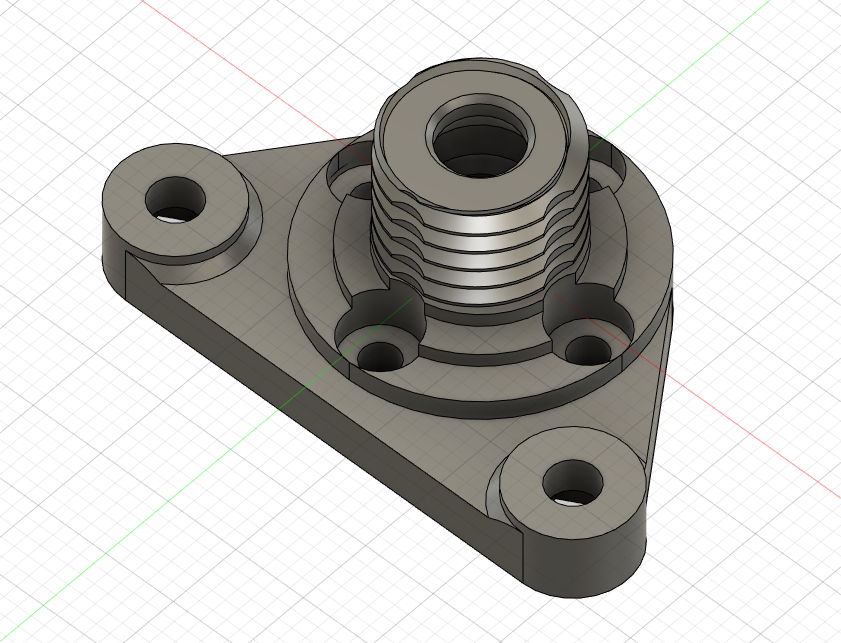

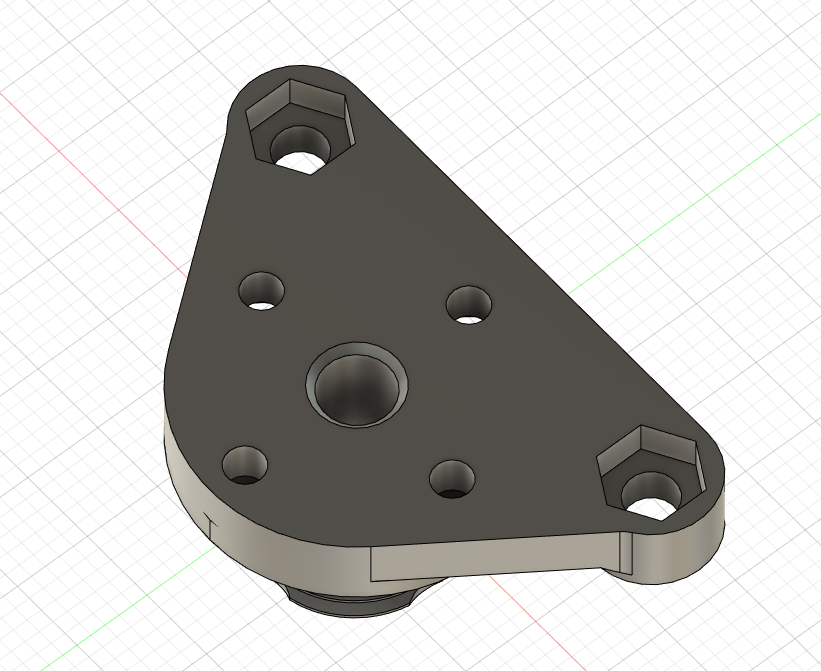

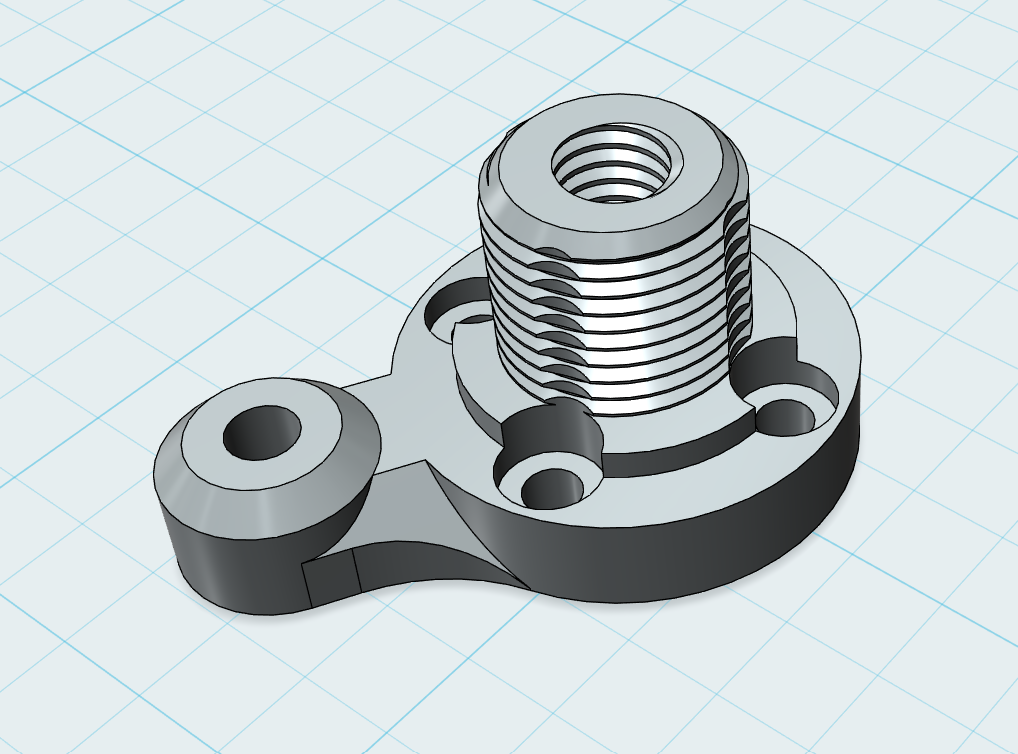

@velvia I'm actually working on something.

https://www.thingiverse.com/thing:4948025I have a Smart Effector v2, I'm not sure if it will fit on a v3.

I am also added a proper inside groove to clip the PTFE tube.

Initially I wanted to use a threaded connector but it is not possible, it would not be strong enough (wall too tin).

This the adapter in printed of PA-CF at .1mm later (I tried ABS+ but it just broke when I tightened the nut) and the nuts with eSun ABS+.

-

@fred-y This looks promising! Will try in CF-ABS or CF-PC. I also have a V2 for some reason. I thought V3 was latest, just got mine today from E3D.

edit: by the way, is that an accelerometer you have behind the bowden tube? What type is it? Would like to try to use one now that RRF is implementing input shaping. -

@velvia I haven't found the time to search details about the v3, I'm not even sure if it has been released to be honest.

I hope Duet3D will make a Smart Effector similar to the Tool Board v1.2 with integrated accelerometer - I designed a mount for it, you can see it on the picture, I will publish it shortly on Thingiverse as well.

A CANBus would be really nice but it won't be retro-compatible with the Duet 2.Anyway, let me know if it requires a few adjustments, the inside groove for the collet has been a little challenging to make, I can easily increase or decrease it.

-

@fred-y I printed on in CF-ABS and it looks to work well. I'm waiting for some M2.5 bolts to mount it to the Dragon. I have a suggestion however: add an "arm" with a hole, so that it can be rigid mounted to the smart effector. One is enough. The it would fit nicely with my 40mm fan shroud as well. Or would you be willing to share .step files?

-

@velvia I was actually thinking to do it after having mounted everything, the hotend turns as I try to tight the nozzle - the advantage for me to install it was actually to don't have to use another tool.

Check this one https://www.thingiverse.com/thing:4947898/files it has 3 arms.

I found it after I published mine, I think that's what you are looking for, I'm not sure this the 2 heatsinks (TriangleLab vs Phaetus) have the same bolt pattern.I might load it in fusion to check, hopefully it works and I can still use the accelerator mount I made

-

@fred-y I tried that one, but it's designed for a PC4 M6 bowden coupler. Yours worked great.

-

@velvia I'm working on it, I'm going to make a 2 and 3 arms version.

I'm pretty sire it can work with my accelerometer mount with no issue.

I will publish when I printed it, I need to check the tolerances for the nuts and make sure it's solid enough.

I hope it won't impact the sensibility of the effector.

-

@velvia I added the new version here: https://www.thingiverse.com/thing:4948025

I printed it but I haven't installed it so far, I will do it tomorrow it need to disassemble by Delta.

Support are not required not the nuts. -

@fred-y couls you share the .step ?

-

@fred-y I remixed that one to have one arm. Step file included: https://www.thingiverse.com/thing:4957839

It still uses M6 PC4 bowden connector though. Ordered one from aliexpress.

The reason I made it with only one arm is because of the 40mm fan shroud I made, which requires the other 2 holes. The model of it is a mess, but it prints without supports and seems to work.

-

@pcr STEP file has been added.

-

@gurusmi said in Smart Effector V3 an plastic nut:

the adapter i talked about ist that Thing. There i printed only the adapter named Dragon_Adapter_v3.stl, It is made for the full dragon hontend and also for the BMO. You will have to take off the BMO's groove adapter. One don't need the Groove Adapter any longer with this design.

I realize that this is an older post I'm replying to. However, this is the first I'm seeing it. As the author of that thing, I'm kind of amused that you are asking any questions about nuts. When I designed the adapter, I realized that there are two different threads being used for smart effectors, and to avoid any issues, I included a .STL file of a nut that works fine. I even mention it in the instructions:

After attaching the adapter to the hotend, simply put the M12 threads of the adapter through the 12mm hole in the smart effector, and attach the printed nut.

I'd suggest scaling the nut to 100.1% if printing at the original size doesn't work. The nut should be a tight fit (to prevent it loosening) but not impossible to thread on the adapter.

I actually prefer using the plastic printed nut to using a metal one for weight savings. I also feel that I can tweak the scaling of the nut in order to make a very tight fit on the threads (which avoids any issue of the nut loosening over time.)

I am happy to see remixes of the thing that add "arms" to prevent rotation of the hotend.

-

@garyd9 Thanks for making the original design and sharing the STEP file