3.4.0 b3 leaning prints

-

@adrian52 the theory I am working on would make it sensitive to the start and end points of the move, the acceleration, the requested top speed, and the input shaping. A cube with infill has a variety of moves with different start and end points, so would make leaning more likely. A hollow cube does the same XY moves over and over again, so you would be less likely to hit a problematic move, but you might hit one if you shift the cube.

Unfortunately, the rod length, delta radius and steps/mm are also likely to affect whether a move is problematic or not.

If you have a simple print that reproduces the problem readily, it would be helpful to me if you can test which of the following changes makes the problem occur or go away:

- Changing acceleration

- Changing requested speed

- If you are using input shaping, turn it off or change the frequency.

-

@adrian52 ok thanks. I will try and do the same. are your test cubes hollow or with infil? are you using input shaping?

-

@t3p3tony I used 10% gyroid infill, and ei3 input shaping

-

@dc42 I have some more to add to the theory

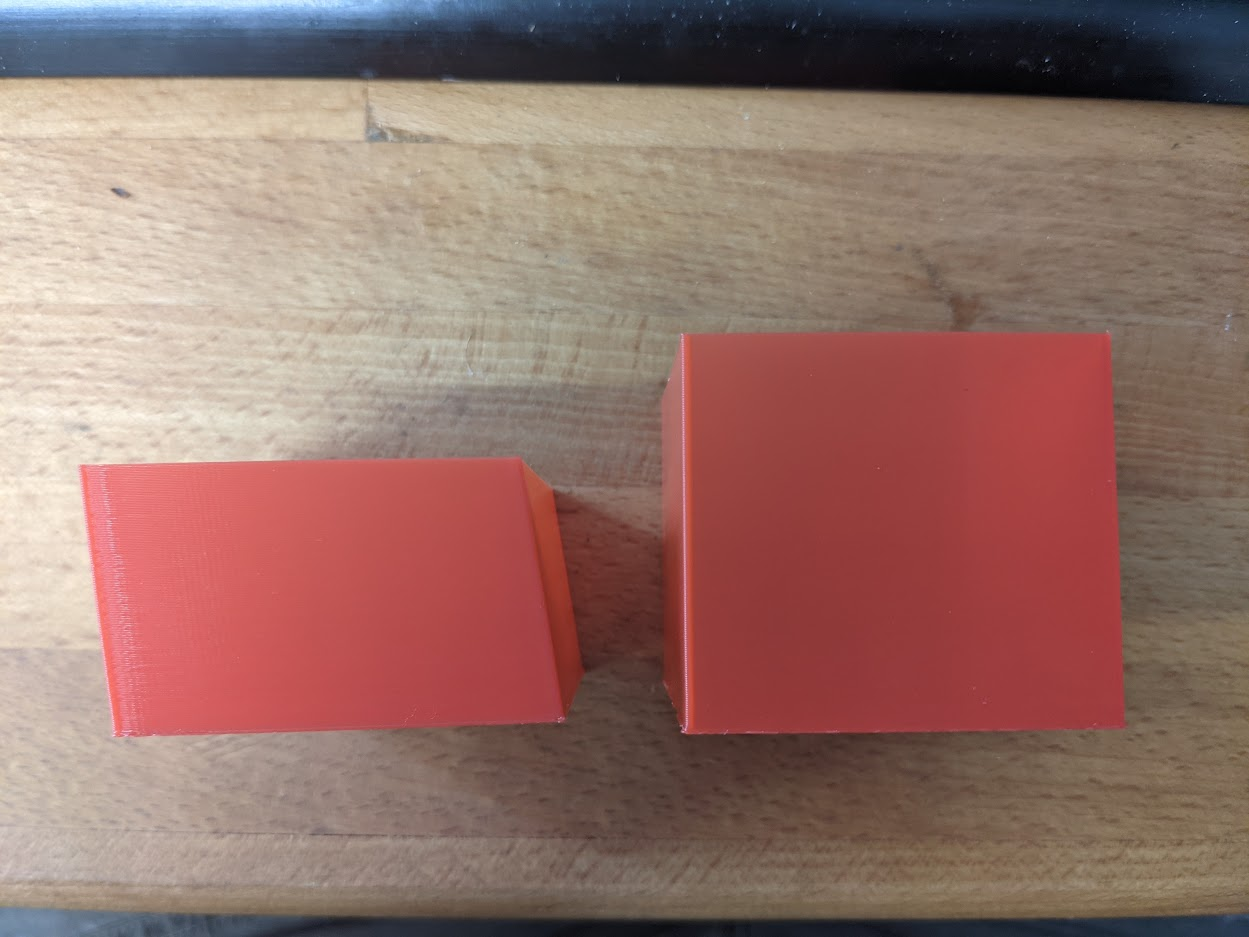

Both cubes are printed with 3.4b3.

The right hollow cube is printed in vase mode.

The left hollow cube was printed as a single wall. This one had a z hop setting of 1mm

I am currently printing the same gcode with no z hop and it is not exhibiting the same leaning in Y.

here is my config; Configuration file for Fly-E3-Pro (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.1-LPC+17 on Wed Jun 30 2021 09:24:28 GMT+0100 (British Summer Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Predator" ; set printer name M665 R227 L450 B185 H400 ; Set delta radius, diagonal rod length, printable radius and homed height M666 X0 Y0 Z0 ; put your endstop adjustments here, or let auto calibration find them ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards using TMC2209 driver timings M569 P1 S1 ; physical drive 1 goes forwards using TMC2209 driver timings M569 P2 S1 ; physical drive 2 goes forwards using TMC2209 driver timings M569 P3 S1 ; physical drive 3 goes forwards using TMC2209 driver timings M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z160.00 E415.00 ; set steps per mm M566 X500.00 Y500.00 Z500.00 E1000.00 ; set maximum instantaneous speed changes (mm/min) next try 3000 M203 X9000.00 Y9000.00 Z9000.00 E10000.00 ; set maximum speeds (mm/min) M201 X1000.00 Y1000.00 Z1000.00 E3000.00 ; set accelerations (mm/s^2) next try 6000 M906 X1344 Y1344 Z1344 E560 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z0 S1 ; set minimum Z ; Endstops M574 X2 S1 P"e1stop" ; configure active-high endstop for high end on X via pin e1stop M574 Y2 S1 P"pson" ; configure active-high endstop for high end on Y via pin pson M574 Z2 S1 P"e0stop" ; configure active-high endstop for high end on Z via pin e0stop ; Z-Probe M558 P8 C"probe" H5 R0.4 F1200 T6000 A9 ; set Z probe type to switch and the dive height + speeds G31 P100 X0 Y0 Z-0.1 ; set Z probe trigger value, offset and trigger height M557 R180 S20 ; define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"e1heat" T0 ; create bed heater output on e1heat and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C M308 S2 P"boardtemp" Y"thermistor" T100000 B4092 ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M207 S4.0 F2400 Z1 M572 D0 S0.4 M955 P0 C"B.1+E.8" I50 ; Miscellaneous M501 T0 ; select first toolI should add that I am using no form of input shaping but I am using PA

-

@jay_s_uk that's interesting! Is the Z hop configured using M207 and firmware retraction, or in the slicer?

-

@dc42 using M207.

The gcode files are the same.

I changed it to 0 using M207 from the console and checked it to ensure it had changed -

@jay_s_uk thanks. Please share the GCode, and I will try it on my delta with Z hop this afternoon.

-

-

@t3p3tony have now tried the two cubes without infill, without input shaping, with z hop=0, and with pa=0, and the slope in the - y direction is the same.

-

@adrian52 so its not z hop.

that just adds to the complexity then -

Here is my config and the example gcode. All my prints were printed in vase mode, no Z hop configured for PETG.

AAP_Dynamic_Acceleration_Adjustment.gcode

; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Delta Settings M665 L440.000:440.000:440.000 R227.102 H449.038 B185.0 X-0.233 Y0.113 Z0.000 M666 X-0.220 Y0.388 Z-0.169 A0.00 B0.00 ; Network M550 P"Apex Predator" ; Set machine name M552 S1 M586 P0 S1 ; Enable HTTP M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable Telnet ; Drives M569 P0 S1 ; Drive 0 goes forwards M569 P1 S1 ; Drive 1 goes forwards M569 P2 S1 ; Drive 2 goes forwards M569 P3 S0 ; Drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping ;Stepper Configuration M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation M92 X160 Y160 Z160 E679 ; Set steps per mm Orbiter greentec E689 @1mm 679 nonlinear M906 X1800 Y1800 Z1800 E550 I11 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ;Normal Speed M566 X900 Y900 Z900 E1200 ; Set JERK(mm/min) M201 X6000 Y6000 Z6000 E3600 ; Set accelerations (mm/s^2) M203 X30000 Y30000 Z30000 E15000 ; Set maximum speeds (mm/min) 18k is 300mm/s M204 P3000 T6000 ; set Print accel and travel accel ; Axis Limits M208 Z0 S1 ; Set minimum Z ; Endstops M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop M574 Z2 S1 P"zstop" ; configure active-high endstop for high end on Z via pin zstop ;Display M575 P1 S0 B57600 ; Z-Probe micro switch M558 P5 C"^e0stop" H2 F460 T12000 A6 ; Set Z probe type to switch and the dive height + speeds 3 Probe Iterations G31 P500 X0 Y0 Z20.567 ; Set Z probe M557 R175 S30 ; Define mesh grid ;Super PINDA ;M558 P5 C"^exp.e2stop" H2 F460 T9000 A3 ;G31 P500 X0 Y-32.750 Z1.775 ;M557 R165 S30 ;Dial Gauge ;M558 P0 ;G31 P500 X0 Y0 Z15 ;M557 R165 S30 ;Filament Sensor M591 D0 P2 C"e1_stop" S1 ;activate Filament Sensor S0 for deactivating ; Bed Heater M308 S0 A"Ultrabase Pro" P"bedtemp" Y"thermistor" T100000 B4300 C0 R4700 ; Set thermistor + ADC parameters for heater 0 M950 H0 C"bedheat" Q250 T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B0 R0.376 C428 D1.14 S1.00 V24.1 ; Disable bang-bang mode for the bed heater and set PWM limit M140 H0 P0 ; Create bed Heater M143 H0 S125 A0 C0 ; Extruder Heater M308 S1 A"Mosquito Hybrid" P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 H0 L0 ; Temperature Sensor ;M308 S1 A"Mosquito Hybrid" P"e0temp" Y"thermistor" T4606017 B5848 C5.548428e-8 R4700 H0 L0 ; blue sensor M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 A0 ; Set temperature limit for heater 1 to 280C M307 H1 B0 R3.324 C137.4 D5.67 S1.00 V24.3 ; Disable bang-bang mode for the Hotend and set PWM limit M570 H1 P15 T15 S120 ;Additional Sensors M308 S2 A"Chamber" P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 ; define Chmaber temperature sensor ;M308 S10 P"spi.cs6" Y"dht22" A"Filament Temperature" ; define DHT22 temperature sensor DATA Pin on E3_Stop ;M308 S11 P"S10.1" Y"dhthumidity" A"Filament Humidity[%]" ; Attach DHT22 humidity sensor to secondary output of temperature sensor M955 P0 S1000 C"spi.cs3+spi.cs4" ; Accelerometer ; Hotend Fan M950 F1 C"fan1" Q100 ;HOTEND FAN create fan 1 on pin fan1 and set its frequency M106 C"HotendFAN" P1 H1 L1 T45 ; set fan 1 value. Thermostatic control is turned on ;Part Cooling Fan M950 F0 C"!fan0+^exp.pb6" Q24000 ;CPAP create fan 0 on pin fan0 and set its frequency !fan2+exp.pb6 Q24000 M106 C"CPAP" P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off L0.3 X1 ; Tools M563 S"NF crazy" P0 D0 H1 ; Define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C T0 ; select Tool 0 ;Extrusion settings M207 S2.5 F3600 R0 T2800 Z0 ;Retraction M572 D0 S0.1 ;Pressure Advance ;standard settings M593 P"ei3" F41.4 ;F Resonance Frequency ;M593 P"daa" F41.5 M703 ;Load filament config M501 ;load config-override -

@cabalsoul thanks. so I have managed to get a lean on "simpler" boxes printed as @Adrian52 suggested, offset in the +/- Y direction. (using gyroid infil and el3 input shaping)

Has anyone observed sloping in any direction other than -Y ?

-

@t3p3tony In my case always -Y.

If i rotate the object it doesn't change anything. -

@t3p3tony in my case it is also always in -y and happens regardless of position on the build plate

-

@t3p3tony It seems that I got one of my prints leaning on both -X and +Y

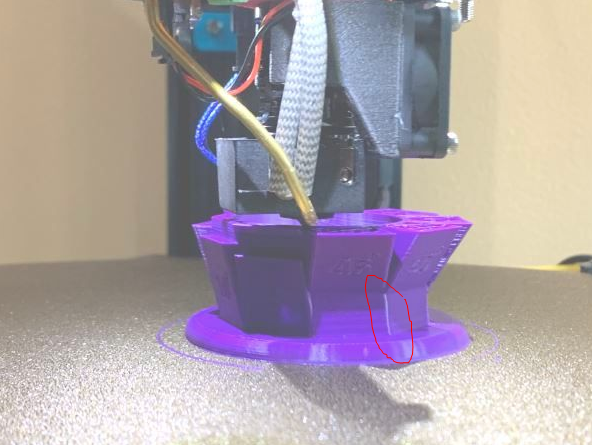

On this picture it is leaning on the left and also back.

I spent quite some time today trying to reproduce the issue on simple objects like basic cubes, calibration cubes, ringing test with and without infill (rectilinear, gyroid...) but all seems fine.

I guess I changed something on SuperSclicer ... I even checked I was still on the beta3.

... I even checked I was still on the beta3. -

@fred-y thanks for spending the time in testing this - it helps!

I will test to see if I can get a lean with the two box prints arranged in different orientations then looking for anything on +/-X

-

With a 20mm cube and a 20x20x10high cube offset in the y direction printed together, the 20mm cube (on the right) looks like this

The left cube for comparison printed with no y offset. You can see that the lean reduces after 10mm, but interestingly a smaller lean is still seen. Havent tried a 45deg rotated cube yet. -

Thanks to everyone who has helped us to try to track this down. @chrishamm has managed to reduce one of your leaning prints to a pair of 2 moves that leaves one of the carriages 2 microsteps away from the correct position. I expect to be able to track down the problem now.

-

@Adrian52 @CabalSoul @DaveA @Fred-Y @jay_s_uk @SIam I have put new firmware builds with a fix for the issue I was eventually able to reproduce at https://www.dropbox.com/sh/kgah0ylh2zu2f7w/AAD2vQOiTQrFly1p22sob6c7a?dl=0. As with all unofficial builds, use them with care.

-

@dc42 thank you exactly what I needed. I am going to test right away.

.

.

.I've tested it and it seems to work. Thanks again.