Bed leveling has lost its mind

-

I've got a big-ass delta that I built and have been running for a couple of years with no real issues.

Some vital stats - Duet 2 wifi controller, smart effector. 500mm diameter print surface. 700mm CF magball arms from Mr Huntley, etc

As I said, I've had very few problems out of this system, and nothing I wasn't able to figure out on my own, until now. Last week, this big bastard tore itself apart on an overnight print. No idea what caused it, but I came in to find several arms pulled loose and the hot end embedded in the print. Fortunately, enough wires got pulled loose for the heater to fault and shut down.

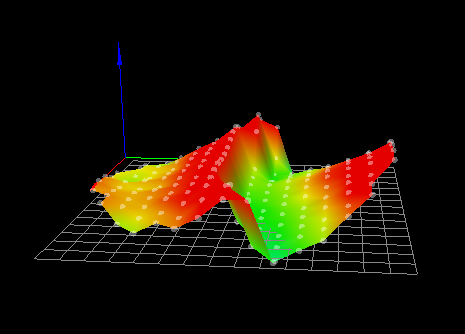

Prior to that, I was getting reasonable bed meshes when running the auto-leveling. Since then, the thing gives me meshes that look like this:

This is 100% repeatable too. (no, the bed isn't warped. At least, not like this)

The pattern here makes me think it's a mechanical issue with one axis but I've been through this thing with a fine toothed comb in the last couple of days and the mechanical aspects of the printer appear to check out fine. Nothing looks out of order.

If anyone has a suggestion, I'd love to hear it -

Boy, I don't have anything definitive to look at, but....

If you're up to it, try changing your config to rotate all the motors and endstops clockwise one position.

Then reprobe the bed.

If the map looks the same, it's probably some static mechanical issue like a carriage bent or an arm that's messed-up.

If it rotates with the new arrangement, it's probably something loose in the mechanical system.

I'm just completely guessing here, but you've got to try something right?

-

That's a really good idea.

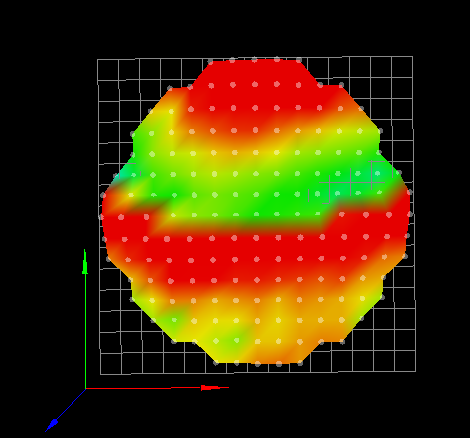

I rotated the motors and endstops per your suggestion and the ridge remained and did not rotate with the motors so it looks like I have a definite mechanical issue.

-

@frobean my initial thought looking at your heightmap is that the sudden jump part way through is due a missed step in one of the towers? If you discount the step, the profile overall looks smooth and reasonable. You also said its consistent with tower position

I wonder if the failure has put a bend in one of your rails/guides at one point that catches and causes a missed step when moving over a certain position on that tower? Might also have messed with any delta calibration you've done

-

Have you checked everything is still absolutely solid within the effector - nothing loose or cracked?

The heatsink nut came loose in my smart effector and caused weird problems until I found it; it's now locktited!

Also check all the magball attachments and rail / belt fittings, belt tension, motor pulley grubscrews etc.

I think a loose motor pulley or some other form of backlash / slop at the side where the high peak is could cause something like you are seeing?Something coming loose is the most likely cause of the initial problem.

If you cannot find anything obvious, I'd try cancelling the heightmap then manually jogging the head around in X and Y, while eg. 5mm above the bed - something easy to "eyaball" as a consistent gap.

Hopefully you should be able to see and track down any variations that could be messing up the height probing.

-

This post is deleted! -

That was actually my first thought. To eliminate the effector as a potential issue, I pulled out my spare smart effector and have been testing with nothing but the magballs and a spare hotend bolted on. It reads exactly the same though. Last night I calibrated it down to snugly hold a sheet of paper between the bed and the nozzle then ordered the effector to various spots around the bed to see where it snags and/or lets go. It quite plainly pinches the paper along that ridge and lets go in the valleys. Argh...

-

@engikeneer The linear rails and frame pieces are far too heavy for the printer to be able to bend them, but I think you have put me on the right track. I've been focusing on the rails, but when I ran the belt past the spot on the rail where any defect has to be, I noticed a slight increase in the drag on the belt. Looking closer at where the belt passes over the pully around that spot, I appear to have a small section where the belt has been stretched and the belt teeth don't mesh perfectly with the pully teeth. That's probably where the effector got stuck and the motor stretched the belt trying to keep going. That stretched spot (about 20-25mm worth of belt) could cause that effect similar to a missed step. Time to order some new belts and see if that fixes it.

-

@frobean that would make sense now I look at your heightmap again as the jump/ridge is arc shaped! I'll claim I was right (even though I was wrong

)

)

If you're feeling keen, you could even swap the damaged belt to be the other way round. You'll still have the stretched section somewherein the loop, but at least you'll be able to prove the ride has gone/moved/changed? -

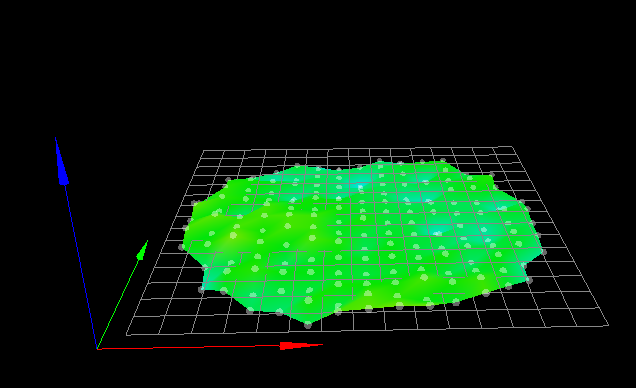

@engikeneer That did the trick!

You can even see the spot where I have a tiny piece of plastic debris stuck under the flex plate in the height map

I've got the stretched spot over where it won't cause any harm until my new roll of belt material gets here.Thanks for the insights!

-

-

@frobean said in Bed leveling has lost its mind:

@engikeneer That did the trick!

You can even see the spot where I have a tiny piece of plastic debris stuck under the flex plate in the height map

You should name your printer "Hubble"

-