ZERO KELVIN HOTEND TEMP

-

@jay_s_uk @chrishamm

made both changesM308 S1 P"temp0" Y"thermistor" A"Bed" T98801 B4185 ; configure sensor 0 as thermistor on pin temp0

M308 S1 P"temp1" Y"thermistor" A"HotEnd" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M950 H1 C"out1" T1 -

@adalton5683 said in ZERO KELVIN HOTEND TEMP:

M308 S1 P"temp0" Y"thermistor" A"Bed" T98801 B4185 ; configure sensor 0 as thermistor on pin temp0

this should be S0 not S1

The S value is the sensor number. You can't have 2 S1's!

https://duet3d.dozuki.com/Wiki/M308 -

@jay_s_uk seems like you just told me to change it to S1 lol

-

@adalton5683 the other one! you have 2 M308's and I highlighted the second one, but instead you changed them both

-

@jay_s_uk ok I made that change

I think I moved my config around after the original post and I think I made that change so it was the only one that was like that to change. anywhoo heres the current c.g

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Tue Jan 25 2022 20:05:51 GMT-0600 (Central Standard Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"bEnder vE3D" ; set printer name ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes backwards M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80 Y80 Z400 E397.5 ; Max Inst Speed Changes - Steps/mm - M566 X900 Y900 Z60 E300 ; Speed - mm/min M203 X9000 Y9000 Z600 E3000 ; Max Speed - mm/min M201 X500 Y500 Z100 E6000 ; Acceleration - mm/s^2 M906 X700 Y700 Z700 E1200 I30 ; Motor Current | mA - Idle | % M204 P800 T4000 ; Print/Travel Acceleration - mm/s^2 M84 S30 ; Idle timeout ; Axis Limits M208 X-117 Y-117 Z0 S1 ; set axis minima M208 X117 Y117 Z250 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io0.in M574 Y1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z M574 Z2 S1 P"io2.in" ; configure active-high endstop for high end on Z ; Z-Probe M950 S0 C"io3.out" ; create servo pin 0 for BLTouch M558 P9 C"io3.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-57 Y-7 Z2.5 ; set Z probe trigger value, offset and trigger height ; Heaters M308 S0 P"temp0" Y"thermistor" A"Bed" T98801 B4185 ; configure sensor 0 as thermistor on pin temp0 M308 S1 P"temp1" Y"thermistor" A"HotEnd" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M950 F0 C"out3" Q30 ; create fan 0 on pin out3 and set its frequency M950 F1 C"out4" Q30. ; create fan 1 on pin out4 and set its frequency M950 F2 C"out5" Q30 ; create fan 2 on pin out5 and set its frequency M307 H0 B0 S1 ; disable bang-bang mode for the bed heater and set PWM limit M307 H1 B0 S1 ; disable bang-bang mode for heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S30 ; set temperature limit for heater 0 to 120C M143 H1 S300 ; set temperature limit for Hot End to 300C ; Fans M106 P0 C"PartCool" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M106 P1 C"HotEnd" S1 H1 ; set fan 1 name and value. Thermostatic control is turned on M106 P2 C"CaseFan" S1 H-1 ; set fan 2 name and value. Thermostatic control is turned off ; Tools M563 P1 S"HotEnd" D0 H1 F0 ; define tool 0 G10 P0 X-25 Y-21 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ;M912 P0 S-13 ; CPU temperature calibration ;M280 P0 S160 ; Clear any alarms M402 ; retract pin just in case ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 ; select first tool ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet -

Does your hotend temp still show -273?

@adalton5683 said in ZERO KELVIN HOTEND TEMP:

M563 P1 S"HotEnd" D0 H1 F0

This should be P0 for tool0. P1 would be for tool1, which I assume you don't have two tools.

Are you assembling this by hand or are you starting with a config from the online generator? https://configtool.reprapfirmware.org/Start

Can you send M98 P"config.g" in the gcode console and report back what it returns? That will check the config for any syntax errors that may get missed during startup.

-

Ran M98 P"config.g:

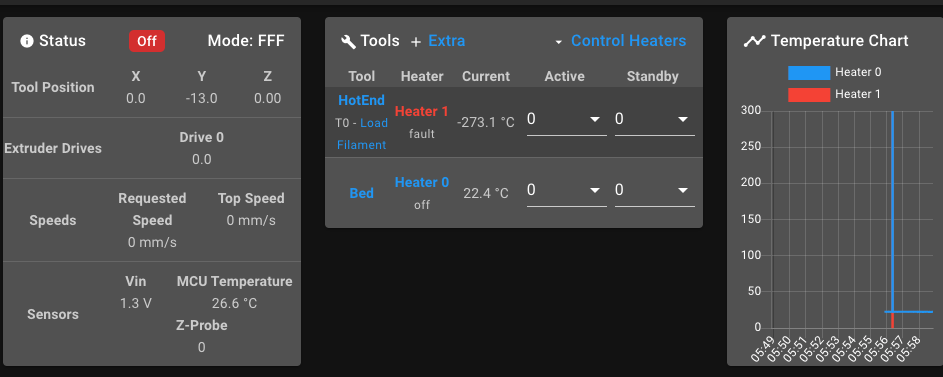

heres everything from the console and then a pic of what the status is still.1/28/2022, 5:56:23 AM Error: Temperature reading fault on heater 1: sensor open circuit 1/28/2022, 5:56:22 AM M98 P"config.g" HTTP is enabled on port 80 FTP is disabled TELNET is disabled Error: bad grid definition: Too many grid points; suggest increase spacing to 11.8mm 1/28/2022, 5:55:48 AM Connected to 192.168.0.27

Heres the config.g

ive even redone the config tool a couple times and since my paneldue arrived I now have that but hoopefully that shouldnt effect this already happening problem.; Configuration file for Duet 3 Mini 5+ (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Thu Jan 27 2022 23:10:21 GMT-0600 (Central Standard Time) ; General preferences M575 P1 S1 B115200 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Enduet 3VED" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes backwards M569 P0.1 S0 ; physical drive 0.1 goes backwards M569 P0.2 S1 ; physical drive 0.2 goes forwards M569 P0.3 S0 ; physical drive 0.3 goes backwards M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z397.50 E409.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z300.00 E6000.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E6000.00 ; set accelerations (mm/s^2) M906 X700 Y700 Z700 E1200 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-115:115 Y-115:115 ; set axis minima ;M208 X235 Y235 Z250 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io0.in M574 Y1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"io3.out" ; create servo pin 0 for BLTouch M558 P9 C"io3.in" H5 F600 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-64 Y-10 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X0:235 Y0:235 S5 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T98801 B4185 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S110 ; set temperature limit for heater 0 to 110C M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C ; Fans M950 F0 C"out3" Q50 ; create fan 0 on pin out3 and set its frequency M106 P0 C"PartCool" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 C"HotEnd" S1 H1 T60 ; set fan 1 name and value. Thermostatic control is turned on M950 F2 C"out5" Q500 ; create fan 2 on pin out5 and set its frequency M106 P2 C"CaseFan" S1 H1:0 T60 ; set fan 2 name and value. Thermostatic control is turned on ; Tools M563 P0 S"HotEnd" D0 H1 F0 ; define tool 0 G10 P0 X0 Y-13 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 ; select first tool -

@adalton5683 your heater and sensor config looks OK to me now. However, your bed heater has faulted. This is probably because it is a slow bed heater and you tried to heat it without tuning it first. I suggest you restart it and see whether the bed heater displays a valid current temperature before you try to heat it.

-

@dc42 so ive restated it many times and its not shown the correct temp. ive tried deleting everything in config-overrid.g and anything that has to do with tunig if it appeared in config.g

so essentially im starting with a fresh install and its showing -273 still

-

@adalton5683 If you are sure that everything is configured correctly but you are still seeing-273, then did you read my post above (27th Jan @ 07:41) ?

-

@deckingman I think our timezones are off so I cant find a post at that time. so can you specify what post.

-

@adalton5683 said in ZERO KELVIN HOTEND TEMP:

@deckingman I think our timezones are off so I cant find a post at that time. so can you specify what post.

The first post after your opening posts.

-

@deckingman

Ok yeah I’ve already check that. The meter is giving me correct resistances on the therm. I did however order a new thermistor anyway just incase. Also checked and rechecked the crimps even checking their resistance. -

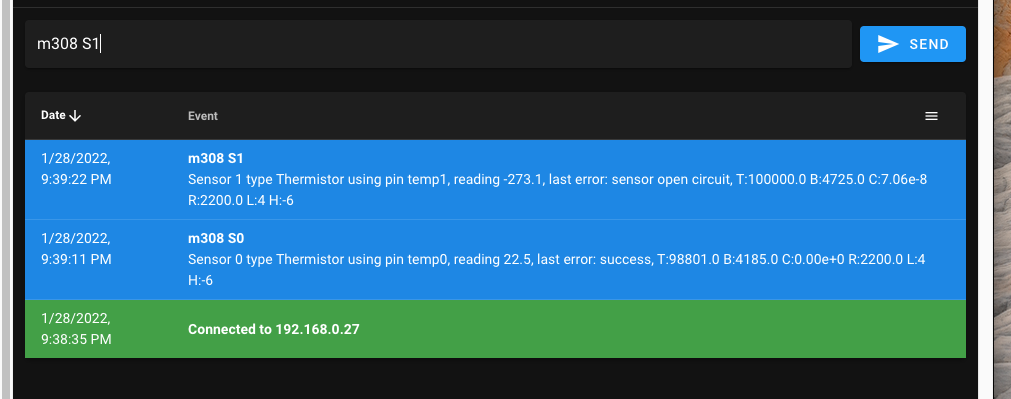

@adalton5683 try sending M308 S0 from the console with no other parameters. It will report the current parameters for sensor 0 and the last error recorded.

-

@dc42 I ran both S0 and S1

also my replacement thermistor arrived so I installed it, just the clipped end.

-

Can you switch from temp1 to temp2 connection on the board and update the M308 to reflect?

M308 S1 P"temp2" Y"thermistor" T100000 B4725 C7.06e-8

Does it still show -273?

Can you make up a much shorter lead for the thermistor to see if it's a break in the wiring?

-

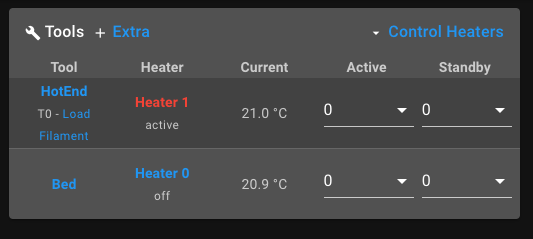

1000 Thanks to you my friend! Your fix did not work bc i didnt try it but it did lend itsself to me finding my hot end thermistor plugged into out6 like a fan when I went to try it. I have no clue how it got there.

looks like its always anoob mistake .

-

So to to the devs, how well does this board handel CNC? ive got a couple CNC builds going rightnow and I ended up buying another one of these boards since I thought I toasted the heater/driver. So I will probably use this second board for a smaller 3 axis NEMA 17 cnc machine. hoping to power mostly everything but the spindle from it if possible.

I heard there is a CNC firmware. whos the main guy on that project?

My other build is a 12Nm NERMA34 4 axis, w/5hp spindle running with 110V in planning on using a rotary phase converter to hopefully get all 3hp out of that spindle. Im assuming this board cannot supply 6A ish per stepper right?

-

@adalton5683 Probably best to ask your CNC question in a new thread in the CNC forum for some more visibility.

https://forum.duet3d.com/category/28/cnc

And you can see some more details here: https://duet3d.dozuki.com/Wiki/Configuring_RepRapFirmware_for_a_CNC_machine