@jay_s_uk ok I made that change

I think I moved my config around after the original post and I think I made that change so it was the only one that was like that to change. anywhoo heres the current c.g

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Tue Jan 25 2022 20:05:51 GMT-0600 (Central Standard Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"bEnder vE3D" ; set printer name

; Drives

M569 P0.0 S0 ; physical drive 0.0 goes backwards

M569 P0.1 S0 ; physical drive 0.1 goes backwards

M569 P0.2 S1 ; physical drive 0.2 goes forwards

M569 P0.3 S0 ; physical drive 0.3 goes backwards

M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80 Y80 Z400 E397.5 ; Max Inst Speed Changes - Steps/mm -

M566 X900 Y900 Z60 E300 ; Speed - mm/min

M203 X9000 Y9000 Z600 E3000 ; Max Speed - mm/min

M201 X500 Y500 Z100 E6000 ; Acceleration - mm/s^2

M906 X700 Y700 Z700 E1200 I30 ; Motor Current | mA - Idle | %

M204 P800 T4000 ; Print/Travel Acceleration - mm/s^2

M84 S30 ; Idle timeout

; Axis Limits

M208 X-117 Y-117 Z0 S1 ; set axis minima

M208 X117 Y117 Z250 S0 ; set axis maxima

; Endstops

M574 X1 S1 P"io0.in" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin io0.in

M574 Y1 S1 P"io1.in" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin io1.in

M574 Z1 S2 ; configure Z-probe endstop for low end on Z

M574 Z2 S1 P"io2.in" ; configure active-high endstop for high end on Z

; Z-Probe

M950 S0 C"io3.out" ; create servo pin 0 for BLTouch

M558 P9 C"io3.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds

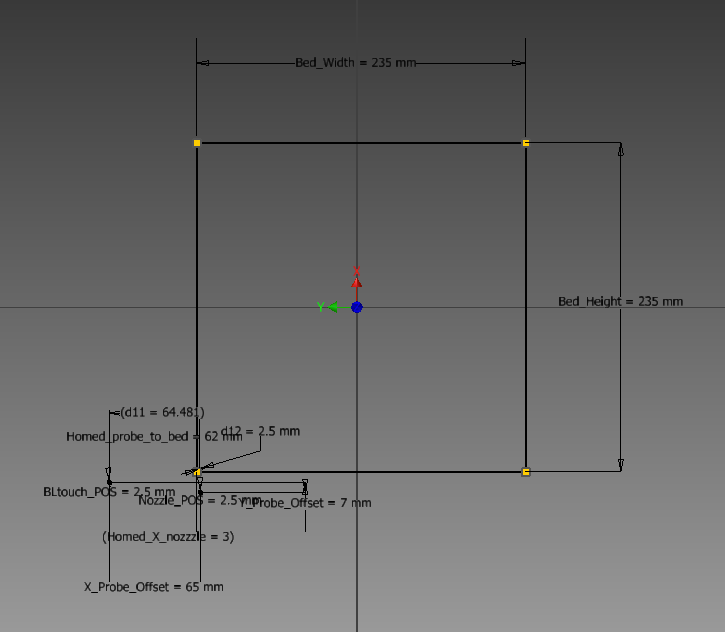

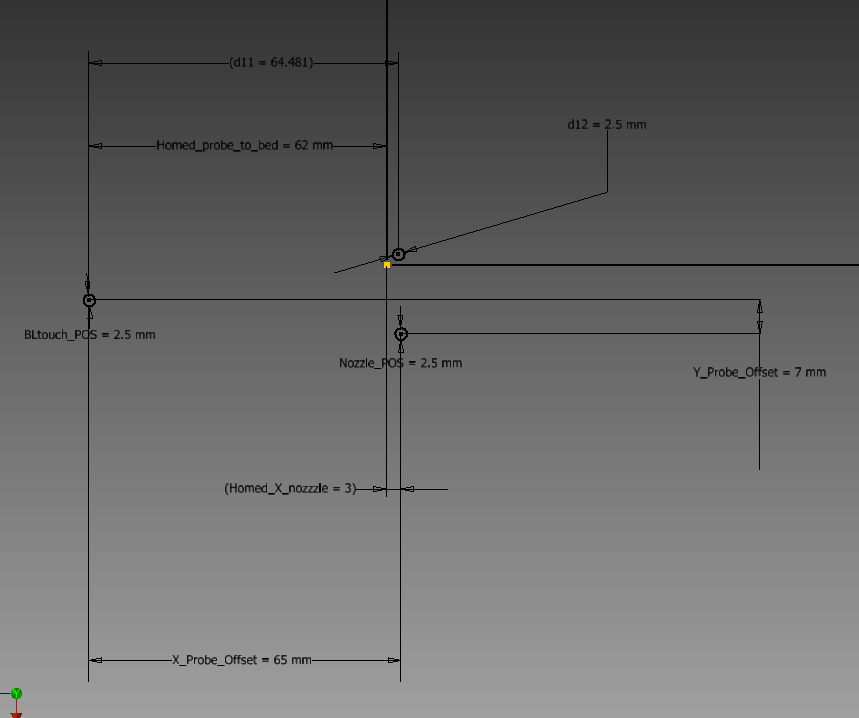

G31 P500 X-57 Y-7 Z2.5 ; set Z probe trigger value, offset and trigger height

; Heaters

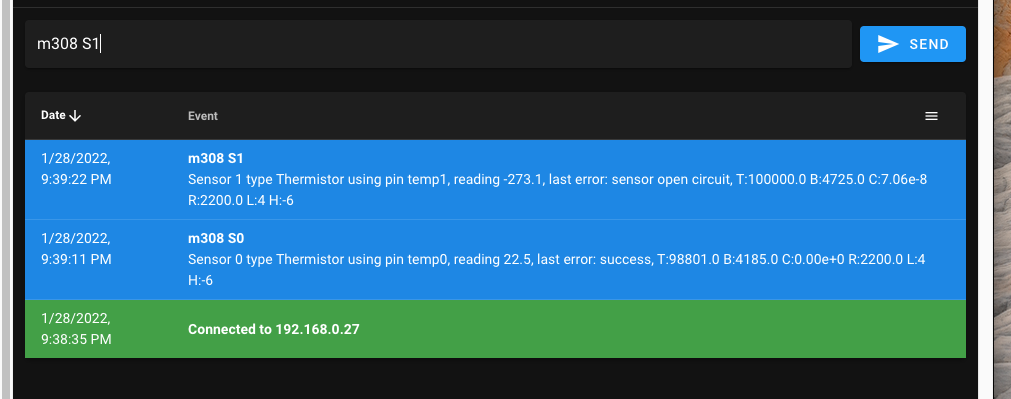

M308 S0 P"temp0" Y"thermistor" A"Bed" T98801 B4185 ; configure sensor 0 as thermistor on pin temp0

M308 S1 P"temp1" Y"thermistor" A"HotEnd" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp1

M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0

M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1

M950 F0 C"out3" Q30 ; create fan 0 on pin out3 and set its frequency

M950 F1 C"out4" Q30. ; create fan 1 on pin out4 and set its frequency

M950 F2 C"out5" Q30 ; create fan 2 on pin out5 and set its frequency

M307 H0 B0 S1 ; disable bang-bang mode for the bed heater and set PWM limit

M307 H1 B0 S1 ; disable bang-bang mode for heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S30 ; set temperature limit for heater 0 to 120C

M143 H1 S300 ; set temperature limit for Hot End to 300C

; Fans

M106 P0 C"PartCool" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M106 P1 C"HotEnd" S1 H1 ; set fan 1 name and value. Thermostatic control is turned on

M106 P2 C"CaseFan" S1 H-1 ; set fan 2 name and value. Thermostatic control is turned off

; Tools

M563 P1 S"HotEnd" D0 H1 F0 ; define tool 0

G10 P0 X-25 Y-21 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

;M912 P0 S-13 ; CPU temperature calibration

;M280 P0 S160 ; Clear any alarms

M402 ; retract pin just in case

; Miscellaneous

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first tool

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet