Random additional steps - interference?

-

@bubblevisor one other idea to throw into the mix is the heated bed. You can often get z banding like syptons from a bed who's temperature varies a bit. Could be down to using bang-bang, a poor PID, or just varying cooling on the bed/print (e.g. as it moves around on an i3).

To me it looks like the bands line up with the changes in the print (e.g. overhangs etc).

I'd also be re-looking at any x/y backlash for similar reasons. -

Is your filament feed smooth and steady?

PID tuned heaters?

Filament quality?

-

@bubblevisor said in Random additional steps - interference?:

I also feel it could be something relating to the duet 3 mini 5+ architecure as I believe I have this problem with another duet 3 mini machine but none of my duet 2 machines.

Possibly relevant is that before RRF 3.4 the drivers on the Duet 3 Mini defaulted to running in stealthChop mode. This can be problematic if the correct tuning move is not executed during homing.

-

I am comparing my good printer with 2 newly built bad printers. They are identical except for the board. The good printer has Duet 2 wifi and the bad printers have duet 3 mini5+ and the fystec big dipper board. Same filament same everything.

-

I am experiencing something similar with a Duet3 6HC .... since I am running very high speeds, my thought was an occasional loss or gain in the x or y direction that curiously seems to self correct. I am currently doing a print at substantially reduced speed to verify that theory.

I call my issue 'banding' because a whole bunch of layers (a band) can be displaced to one side before the system switches back to the right position. The band appears to be positive on one side of the model and negative on the other side which supports the theory of everything shifting over by a few micro steps. -

This is what my print looks like:

If you magnify the image, you also see random bumps in the layers which is probably an unrelated issue.

-

Doing a vase mode print of a flat walled cylinder could be useful here.

@jens55 Do those bands happen to correspond with direction changes? As in, those layers are going left to right, rather than right to left? Meaning perhaps backlash.

-

I have swapped out the extruder, the z motors/leadscrews - no change.

-

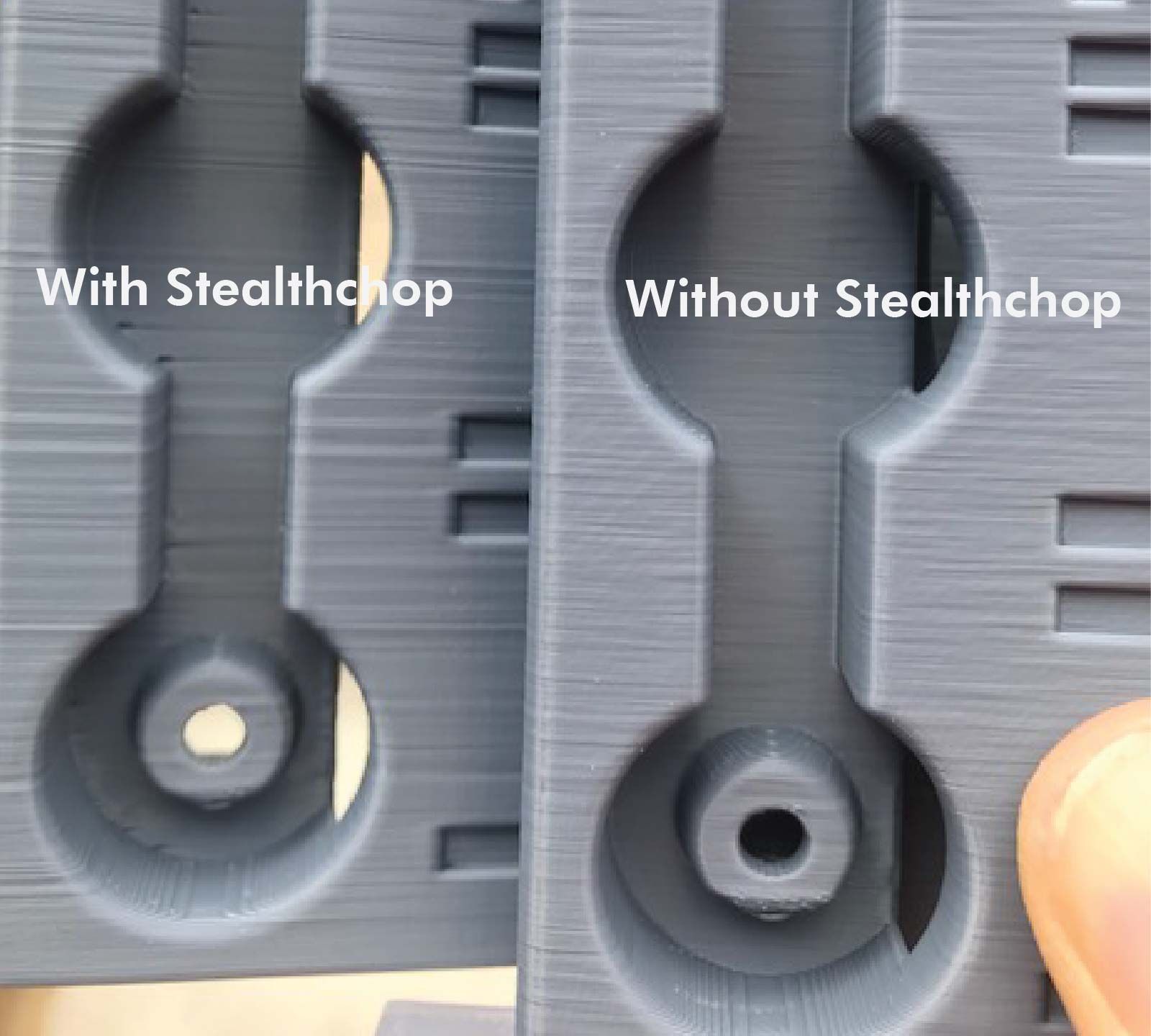

Photos showing my good printer vs bad

-

What layer height is that?

-

@bubblevisor said in Random additional steps - interference?:

Photos showing my good printer vs bad

What are the differences between the two machines?

-

0.2mm layer height ESUN ABS with enclosure at 60degrees C.

-

Only difference is the board. Good printer is Duet 2 wifi bad is duet 3 mini 5+ and other bad printer is big dipper. Both bad printers' prints look exactly the same.

-

@phaedrux The stealth chop point seems potentially likely as the good printer is running RRF3.3 on Duet 2 spreadcycle and bad printer is 3.4 on big dipper TMC2209 defaulting to stealthchop with a weird speed threshold that switches to spreadcycle. This sounds like it can give rise to inconsistencies.

I'll change the M569 to enforce spreadcycle and report back. Fingers crossed.

-

@phaedrux, I don't think direction of travel has any bearing here but I will check that motor pulleys are tight once the current print is finished (tonight). I am pretty sure I loctited them last time I had an issue .... which btw also was intermittent in a way as the pulley could move a bit but not easily so sometimes it moved and other times it didn't.

Great suggestion !!!

As far as 'normal' backlash, I would have expected the artifacts to be very repeatable as every layer in this model is identical to the previous layer ..... but as I said, a pulley has caused something like that before. -

I had a chance to check the motor pulley on x and y and they are tight. The same model as printed before but with considerable speed reduction (300 mm/s to 200 mm/s) produces a much better surface finish and only two small position shifts in only one axis. I left the acceleration at 15000 but am now printing again with a reduced acceleration of 10000. I still have infill and inner wall speed set at 300 mm/sec.

The only other issue I have are the zits that appear randomly. There are two kinds of zits - some are sitting on the outside of the wall and these can be scraped off with only a finger nail. There are however little bumps that are completely enclosed and I am thinking these might be caused by issues with the faster infill speed. These last bumps are not really a problem but more of an annoyance.

Anyway, I was just printing too fast. This is with a Jubilee printer and quite honestly it's a bit disappointing that I can't go faster. -

BINGO! I turned off the default stealthchop and enabled spreadcycle via M569. Completeley solved the problem.

Default Stealthchop switches back and forth between spreadcycle and stealthchop when the speed is low. This seems to create a print blemish when this happens. My advice is STICK TO SPREADCYCLE!

-

@dc42 THanks for your help. You were spot on!

-

undefined dc42 marked this topic as a question

undefined dc42 marked this topic as a question

-

undefined dc42 has marked this topic as solved

undefined dc42 has marked this topic as solved

-

Glad to help.

-

@bubblevisor if you set the changeover speed to below the jerk value, then at least you get quiet motors at standstill.

Ian