LIS3DH adafruit and duet3 mini5 not working

-

Can´t get connection to adafruit LIS3DH, and my duet3 mini5+

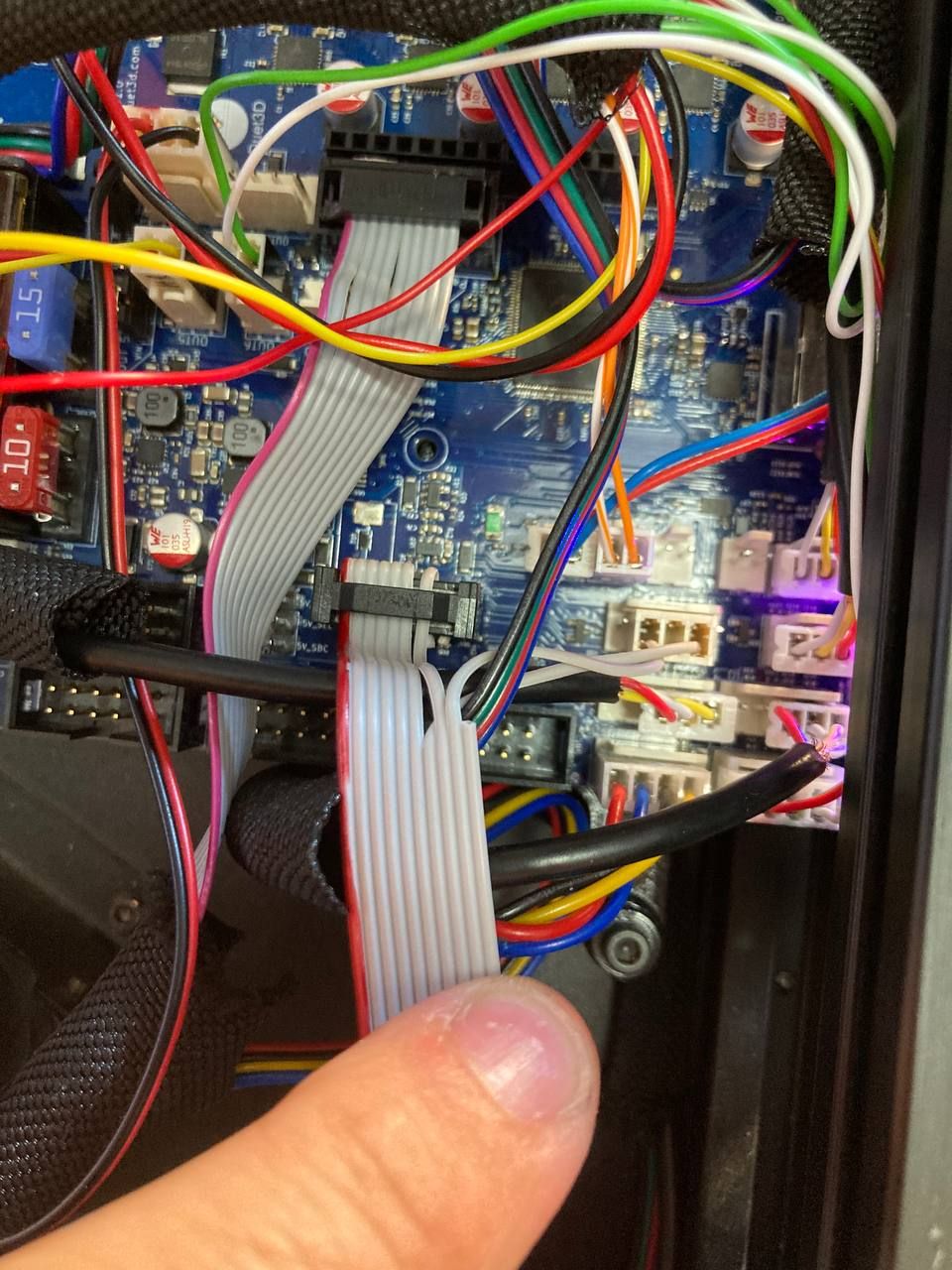

; config.g ; Called on power-up of the Duet Electronics ; General preferences G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves ; Network M550 P"KaPredator" ; Set machine name M552 S1 P192.168.0.53 ; Set IP M553 P255.255.255.0 ; Set subnetwork mask M554 P192.168.0.1 ; Set gateway M586 P0 S1 ; Enable HTTP M586 P1 S0 ;C"*" ; Allow FTP and Cross Origin Resource Sharing (CORS)for DueUI M586 P2 S0 ; Disable Telnet ; Delta Settings volcano M665 L440.833:440.833:440.833 R235.101 H411.820 B190.0 X0.142 Y0.077 Z0.000 M666 X-0.080 Y-0.073 Z0.153 A0.00 B0.00 ; Drives direction M569 P0.0 S0 D3 ; Drive 0 @X M569 P0.1 S0 D3 ; Drive 1 @Y M569 P0.2 S0 D3 ; Drive 2 @Z M569 P0.3 S0 D3 ; Drive 3 @E M584 X0.0 Y0.1 Z0.2 E0.3 ; Map drivers ; Steps M350 X16 Y16 Z16 I1 ; Configure micro-stepping with interpolation for X, Y, Z M350 E16 I1 ; Configure micro-stepping with interpolation for E M92 X80 Y80 Z80 E691 ; Set steps per mm ; Speed, Acc and Jerks M203 X36000 Y36000 Z36000 E4200 ; Set maximum speeds (mm/min) M201 X4000 Y4000 Z4000 E3000 ; Set accelerations (mm/s^2) M204 P1000 T4000 ; Set printing and travel accelerations M566 E600 ;600 ; Set maximum instantaneous speed changes (JERKS) (mm/min) ONLY EXTRUDER M205 X8 Y8 Z8 ; Set maximum instantaneous speed changes (JERKS) (mm/seg) XYZ . USE this for Marlin COMPATIBILITY ; Stepper Current M906 X1250 Y1250 Z1250 E350 I30 ; Set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 Z-1 S1 ; Set minimum Z ; Endstops M574 X2 S1 P"io2.in" ; Set active high endstop on X on pin xstop M574 Y2 S1 P"io3.in" ; Set active high endstop on Y on pin ystop M574 Z2 S1 P"io5.in" ; Set active high endstop on Z on pin zstop ;Accelerometro M955 P0 C"io4.out+io4.in" I50 ; Set Accelerometro on IO4 ; ========================================================================================================= ; filament handling ; ========================================================================================================= ; ; execute macros that has the status of the filament sensor ; M98 P"0:/sys/00-Functions/FilamentsensorStatus" ; ; ========================================================================================================= ; ; ZProbe M558 P8 R0.4 C"io1.in+io1.out" H5 F1200 T9000 ;A3 S0.03 ; set Z probe type to effector and the dive height + speeds G31 K0 P100 X0.0 Y0.0 Z-0.18 ; set Z probe trigger value, offset and trigger M557 R170 S25 ; Define mesh grid ; ; Heaters ; Heated Bed M308 S0 P"temp0" Y"thermistor" T100000 B3950 C0 A"Bed" ; Define Sensor0 as the heated bed temperature TRY B4300 M950 H0 C"out0" T0 ; Define Heater0 as the heated bed, bind to Sensor0 ; PID M950 H0 C"bedheat" T0 ; Define Heater0 as the heated bed, bind to Sensor0 ; PID M140 H0 ; map heated bed to heater 0 M143 H0 P0 S120 A2 ; disable temporarily H0 if temp exceeds 120C M143 H0 P0 S130 A0 ; heater fault H0 if temp exceeds 130C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M570 H0 P60 T15 S0 ; heater fault for 60seg of 15ºC excursion ; ; Hotend1 M308 S1 P"temp1" Y"thermistor" T100000 B4725 C7.06e-8 A"Hotend" ; Define Sensor1 as Extruder0 temperature M950 H1 C"out1" T1 ; Define Heater1 as Extruder0 heater, bind to Sensor1 M143 H1 S275 A2 ; disable temporarily H1 if temp exceeds 275C M143 H1 S285 A0 ; heater fault H1 if temp exceeds 280C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M570 H1 P10 T30 S0 ; heater fault for 10 seg of 30ºC excursion ; ; Heater model parameters M307 H0 R0.408 C457.073:457.073 D1.85 S1.00 V24.5 B0 M307 H1 R2.080 C254.185:184.546 D10.06 S1.00 V24.5 B0 ; ; Fan0 = Part Coooling M950 F0 C"out6" Q160 ; Define Fan0 for Part Cooling (2x Delta BFB0412HHA-A), 500Hz PWM M106 P0 S0 H-1 B0.4 ; Set Fan0 to default off, manual control ; ; Fan1 = Hotend M950 F1 C"out5" Q500 ; Define Fan1 for Hotend cooling, 500Hz PWM M106 P1 S1 H1 T45 ; Set Fan1 to Thermostatic control, max RPM at 45C ; ; Fan2 = MotherBoard Cooling ;----MCU & DRIVERS sensors------ M308 S3 Y"mcu-temp" A"MCU" ; create sensor for MCU temp M308 S3 Y"mcutemp" M308 S4 Y"drivers" A"Drivers" ; create sensor for drivers temp M308 S4 Y"drivers" ;M912 P0 S-0.8 ; Calibrate MCU temp M950 F2 C"out3" Q500 ; create fan 2 on pin out4 - alternative with tacho M950 F2 C"!fan2+^pb6" M106 P2 H3:4 L.3 B.5 X1 T40:65 ; Set fan 2 PWR fan. Turns on when MCU temperature, hits 45C and full when the MCU temperature reaches 65C or any TMC2660 alarms ; ; Tools M200 D1.75 M563 P0 S"T0" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets G10 P0 S-274 R-274 ; Set initial tool 0 active and standby temperatures to 0C M302 S180 R180 ; allow extrusion starting from 180°C and retractions already from 180°C ; ; Additional Settings M404 N1.75 ; Define filament diameter for print monitor M207 S0.85 R0 F2400 Z0 ; Firmware retraction ; ; LCD M575 P1 S0 B57600 ; Set Baudrate to 57600 ; ; LEDS M950 P0 C"out4" Q1000 ; Leds life ; ; Miscellaneous ;G29 S1 ; Load bed mesh ;M376 H10 ; Mesh bed compensation. Height must be set to at least 20x the maximum error in the height map (max 5%) M911 S23 R24 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss T0 ; Select first tool (Extruder 0) M501 M302 S180 R180 ; allow extrusion starting from 180°C and retractions already from 180°C

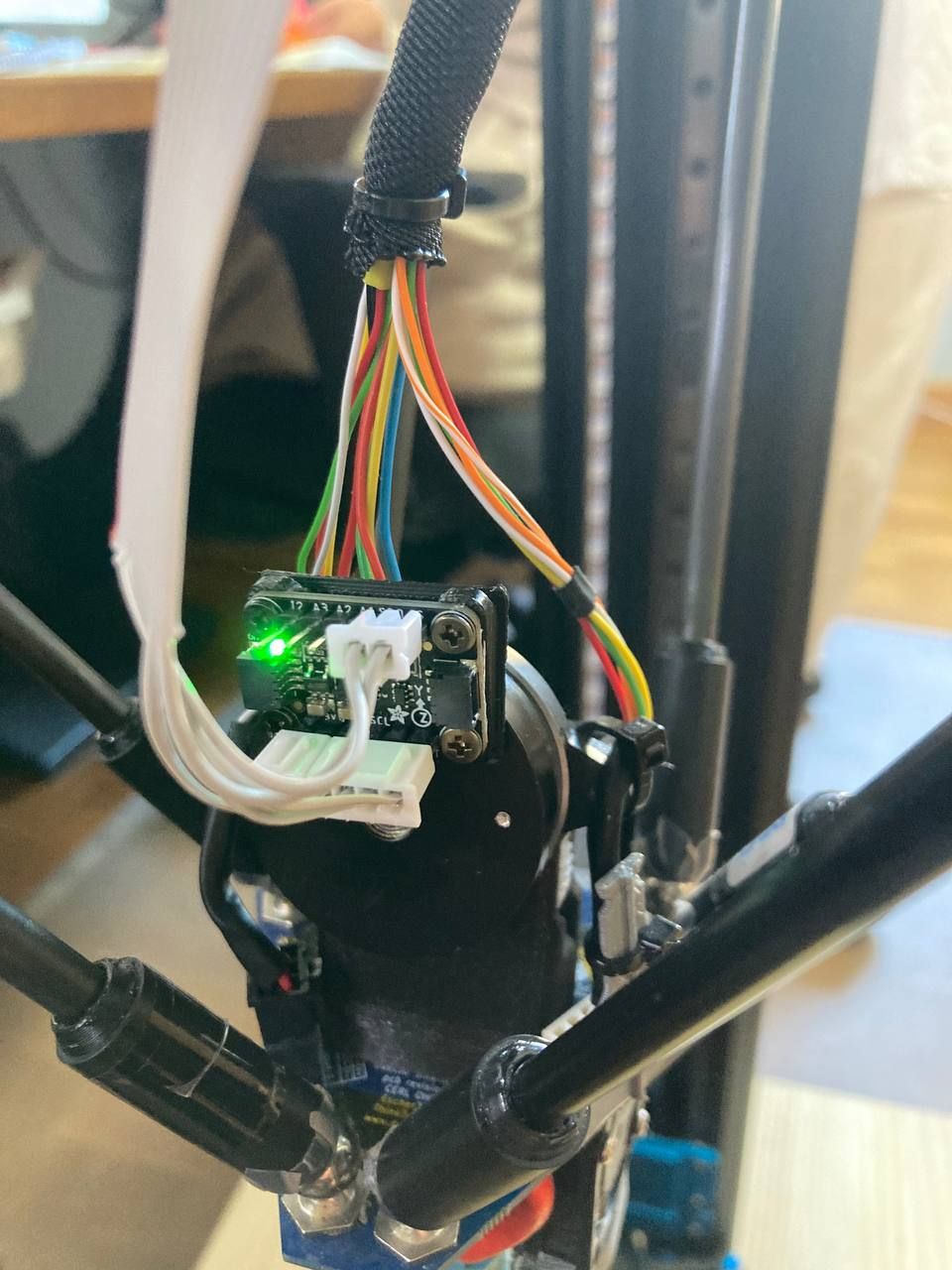

Error like this....I followed the wiring from https://docs.duet3d.com/User_manual/Connecting_hardware/Sensors_Accelerometer

M955 P0 Error: M955: Accelerometer not found -

@apak how long is that cabling?

ideally you should go for screened wiring and not flat ribbon cable. I run an accelerometer with a 2.7m USB3 cable -

@jay_s_uk 1m or so

How do you do it with usb3 cables. You need 8 wires. Could you share your setup?

-

@apak Luckily a USB3 cable has 8 connectors (plus some screening), see: https://forum.duet3d.com/topic/22878/software-package-3-3beta3-released/68?_=1624809172098

-

@gloomyandy

@jay_s_uk

got it working,

now I need to now what should I do with it.It´s a delta printer