e3d TC coupler motor is not moving and homing C has no errors?

-

I'd firstly for ease of use move your M584 to after you drive definitions.

And I can't see any axis limits for the coupler?

-

@voodoobane The normal setup on an e3d toolchanger is not to have any sort of endstop for the C axis. Instead the motor is just driven until it hits the physical stop (the homec.g file will normally reduce the motor current during this process). It looks like you have a stall detection endstop defined. Perhaps that is causing problems. DC42 published his toolchanger configuration here: https://github.com/Duet3D/RRF-machine-config-files/tree/master/E3D_Tool_Changer/dc42-duet3-centreZero-2Titan-2Hemera/sys

I have something very similar setup on my TC and it seems to work fine...

-

Stall detection does not work for the coupler stepper.

Here are the relevant bits from my code:

; from config.g file ; C (tool coupler) (M92 is set so G1 commands are in degrees) M92 C182.044 ; ( 32 steps-per-rev (stepper) * 64 (gearbox) * 2 (gears) * 16 (microsteps) ) / 360 M203 C5000 ; max speed (mm/min) (default 300) (suggested 5000) M201 C500 ; acceleration (mm/s^2) (default 20) (suggested 500) M566 C2 ; max instant speed change (jerk) (mm/min) (default 12) (suggested 2) M906 C500 ; motor current (mA) (stepper rating 400mA RMS per phase) (suggested 500) M350 C16 I1 ; 16x microstepping with interpolation M208 C-41:225 ; set axis min/max values (determined by testing); --- homeC.g --- ; --- compute max C rotation --- var cmin = move.axes[3].min var cmax = move.axes[3].max var ctot = {var.cmax} - {var.cmin} ; --- home C --- M400 ; wait for any moves to finish M913 C50 ; insure "normal" stepper current G91 ; relative moves G1 H2 C{-var.ctot} F5000 ; turn CCW to limit of rotation G92 C-41 ; set logical position (determined by testing so unlocked is 90, locked is 180) M98 P"tool_unlock.g" ; turns to 90; --- tool_lock.g --- M400 ; wait for moves to finish M913 C100 ; increase current to improve locking G90 ; absolute moves G1 C180 F5000 ; turn to locked position M400 ; wait for moves to finish M913 C50 ; restore current to normal; --- tool_unlock.g --- M400 ; wait for moves to finish M913 C100 ; increase current to improve unlocking G90 ; absolute moves G1 C90 F5000 ; turn to unlocked position M400 ; wait for moves to finish M913 C50 ; restore current to normalFrederick

-

I agree with Rushmere3d, you need to add some limits for C.

I have 0 and 500 on mine.

; Axis Limits NEED CHANGING FOR TC. CONSERVATIVE GUESS NOW for XY M208 X-14 Y0 Z0 C0 S1 ; set axis minima M208 X330 Y265 Z350 C500 S0And this is my home C file:

; homec.g ; called to home the C axis (coupler) ; ;G91 M400 G92 C499 M400 M913 C60 ; MOTOR TO 60% CURRENT G1 H1 C0 F2000 ; M400 G92 C0 ;G90 M913 C100 ; MOTOR TO 100% CURRENT G1 C0 F10000 ;Open Coupler M98 P"/macros/Coupler - Unlock"I have the lock position as C33 and unlock as C125

-

I will try this guys!

-

All I see is the homeC.

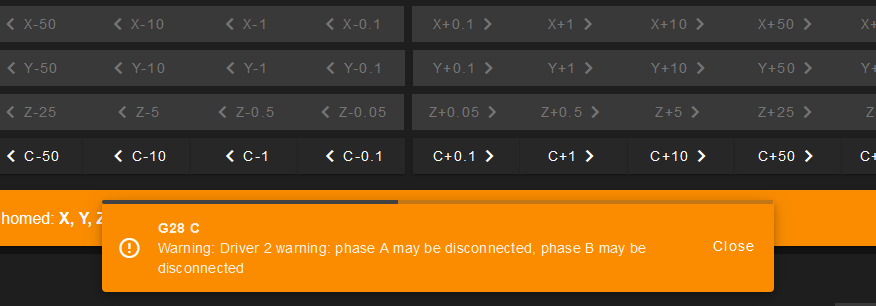

But no I have another problemIs it normal if this isn't all set to have the Home C tell me the wiring is wrong? I have a 2nd motor just in case. and it gives me the same error. I double-checked my wiring and everything. I do not understand it is saying my wiring is bad. could s0 and s1 be a factor? I have little information about this tool changer motor.

-

@voodoobane I checked the A and B poles and they are correct.

-

@voodoobane said in e3d TC coupler motor is not moving and homing C has no errors?:

Is it normal if this isn't all set to have the Home C tell me the wiring is wrong?

What message are you seeing, and what firmware version are you using?

-

@dc42 I using Version 3.4

-

@dc42 I figured it out... Driver 2 is bad...

-

How did you determine that?