weird signal from duet to motor

-

@payton The commented out steps/mm you have for extruders will probably have been causing issues. for example 24186 steps/mm with with a feedrate of 6000mm/min would be a step rate of 24.1186Mhz The 6HC can support approx 300Khz on multiple concurrent axis.

In the current configuration for M350 you have E1:1 so full stepping. In general that's not a good way to control stepper motors Try E16:16. I commented out Lines of M350 you have 128 microstepping, this is supported however if you want to move at high step rates we advise you use 16 microstepping with interpolation.

So i would try M350 E16:16, adjust M92 as needed to get the correct steps/mm (probably 3312). that should allow feedrate up to approx 900mm/s or F54000 (it may be a bit lower than this in reality depending on what else the processor is dealing with it.

I would say that a an extruder feedrate of F10000 (as opposed to a movement feedrate) is really high. Is this for filament load and unload?

-

@t3p3tony we are using servos as i have been told, would that have the same problems of running in full step?

as to the feedrate this is a 2 in 1 out extruder, so F16000 for the extruder as a whole should be F8000 per motor.

-

@payton ahh ok, so how are you getting the step/direction signals out of the 6HC?

But yes if you are using servos then the distinction between steps and microsteps does not matter as such you just sent the servo a certain number of step pulses and it moves the amount it is configured to move.

So you have the correct pulse timing set for the connections to the servos?

-

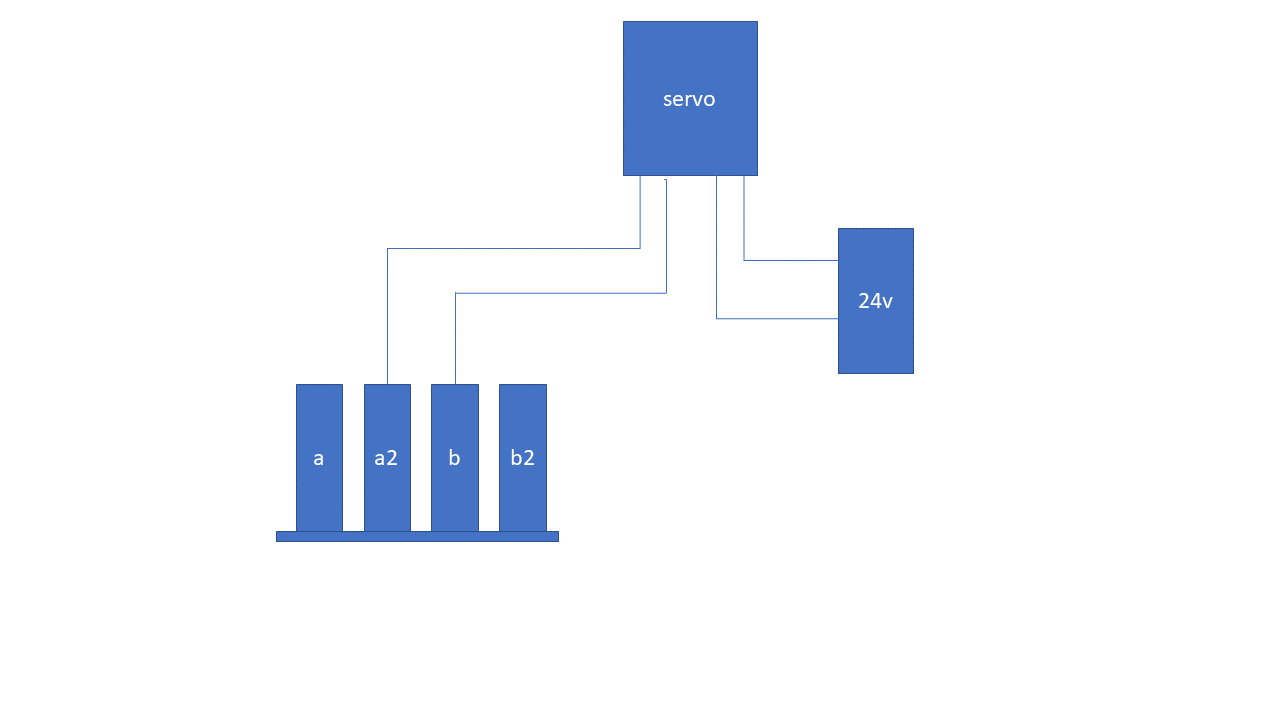

@t3p3tony to get signals out of the 6HC we wire two of the four leads to the A2 and B1 sides of the servo pins (middle 2) on the board. then we wire the other two to power and neutral 24v. this is the same setup as the duex5 I believe.

i do not know what the pulse timing is supposed to be, but here is the M569 of the servo pin

m569 p0.5

Drive 5 runs forwards, active low enable, timing fast, mode spreadCycle, ccr 0x08053, toff 3, tblank 1, thigh 200 (1.1 mm/sec), hstart/hend/hdec 5/0/0, pos 896 -

@payton can you provide a schematic of how you are connecting the 6HC to the servo and the servo datasheet please. I have not seen this method of controlling a servo controller before.

-

@t3p3tony here is the schematic of the servo. this is servo pin 0 and a power in parallel to the board power, let me know if this is to simple.

-

@payton what's the servo part number?

-

@jay_s_uk I have been made aware that they are indeed stepper motors and not servos. and my supervisor is contacting the company we got them from to find the part number.

-

@payton that clears a lot up then.

the part number should be printed on them, but if not, that information would definitely help -

@payton that is a very odd way to drive a stepper motor. the driver on the 6HC is designed to drive a bi polar stepper motor up to 6.3A. would be interesting to understand why this connection scheme is used and not connect both coils to the drivers (assuming it is a bi polar stepper)

-

@t3p3tony

so when we asked for the motor specs it was revealed it is a servo with an internal driver that reads a stepper driver input. in the instructional video they plug it into a duet the same way, so it comes back to the weird signal from the board.looking back at the scope it doesn't look like noise per say, but more like signals combineing/ cutting out at weird times.

-

Do they also provide settings for the Duet?

-

@payton please post the data sheet.

-

@phaedrux so I think I have solved the problem

I looked at the motor config recommendations, and found that we had interpolation on for the M350 command. I turned it off and I could spin the motor at 13000 with the full 8.25 expected rotations.

now I want to verify I am understanding the problem fully and why this worked. because the duex still works and still has interpolation on. how could this be?

-

@t3p3tony said in weird signal from duet to motor:

@payton please post the data sheet.

-

@t3p3tony I am having trouble finding the datasheet, it is a different company that makes it so it may not be available.

-

I'm using a 6HC with Tecnik Clearpath SDSK stepper/servos and ended up tapping the step and direction signals from test points on the backside of the 6HC and running them through a Duet2 BoB to get them to the 5V levels inputs the Clearpath wants. It was a bunch of tedious hand work but the result has been rock solid. I agree with T3P3Tony that tapping one end of each motor coil is a weird setup.

-

@t3p3tony Thank you for all your help, I do not think I can get the datasheet, if I ever do I will post it here.

to summarize the problem and solution for future readers:

I had an extruder motor for the printers at work that did not spin the correct amount at high speeds on all printers but one. it was a servo that took stepper motor signals from the servo pins to command the driver. it needs a full step signal to work.

although in the config we had turned micro stepping to full step, we had interpolation on, witch does a minor bit of micro stepping even if that motor is set to full step. the reason the one printer did not have this issue was because it was the only one running with the duet 2, which does not support interpolation unless the drive is set to x16 micro stepping. so with the same config it would run the motor properly

thanks for all the help everyone

-

undefined Payton has marked this topic as solved

undefined Payton has marked this topic as solved

-

@payton thanks for the explanation. I am still intrigued to see this method of driving a servo from the full step output of a stepper driver.

-

@coseng I am using a 6HC with duet 3 Expansion 1XD board for step and direction connected with the Can Connectors. Originally to steppers but now to (2) ClearPath SD driving the X axis. When the motors are running at high speeds, they will appear to loose steps. Could you give more detail on how you are getting your step and direction signals? I saw other posts have had this issue but I haven't found anyone with a solution.