Lopsided thread

-

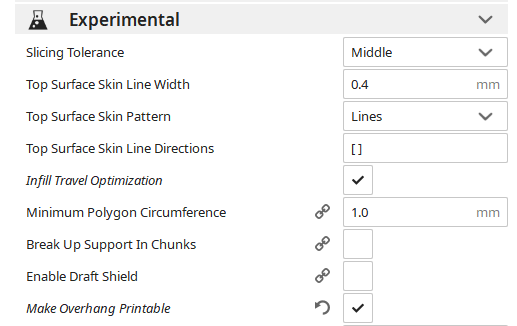

Maybe you have activated "make overhangs printable"?

-

@diy-o-sphere, checked ... not enabled. Thanks for the comment!

I am printing the thing again on the hope that the printer had a case of temporary insanity.

I looked through the preview layer by layer and the thread is formed exactly as it should with symmetrical upper and lower thread faces. The matching nut 'seems' to have symmetrical threads although it's kinda hard to see. Of course the nut doesn't fit the thread because of tolerances and possibly because of the distorted thread. On the nut, each side of the thread has been offset by -0.3 mm for clearance but that isn't enough clearance yet. -

Second print came out exactly as first print ... now trying a third print but this time with a 0.1 mm layer height .....

-

This is getting really weird .... when I print with a 0.1 mm layer height, around half the thread (as I go around the circumference once) prints ok (symmetrical) and the other half is flat(ish).

I am now resorting to more clearance in the matching nut because I have run out of ideas of what else I could try to print this properly. -

@jens55 Maybe the overhangs are lifting because extrusion temperature is too high, or cooling is insufficient on one side?

Ian

-

@droftarts said in Lopsided thread:

@jens55 Maybe the overhangs are lifting because extrusion temperature is too high, or cooling is insufficient on one side?

Ian

I second that. It looks to me like it's curling upwards on one side (the left in the image) so maybe the part cooling air is only hitting the right hand side?

-

My money is also on uneven cooling. With threads / steep overhangs like this, it also helps to print the walls inside-out.

-

Thanks guys, I will try printing inside out and increasing cooling air.

-

WoooHooooo ..... we have a winner !

I was at 30% cooling, tried 60% with only a tiny difference and then went to 90% when I got a perfect thread form!

The walls were always set to normal sequence (inside-out)

I did notice the slight curling as well but I would never have thought that my issue would be caused by insufficient cooling.

I was printing in PLA so I guess in retrospect it wasn't totally unexpected.THANKS !!!!

-

After the problem is solved, but thought I'd pass this on. "Normal" machine threads are cut at an angle of 60 degrees, so when you print, you've got a lot of overhanging perimeter. Also as the thread prints, each layer shape in the threaded area is exaggerated at the farthest overhang (look at a layer in the slicer). The result is a risky edge that often curls up (at least mine do). One answer is more cooling. Another is to lower the filament temperature as much as possible, because it improves cooling.

If I am3D printing both the male and female threads, I modify the thread profile to eliminate the 60degree bit. The easiest way (for me) in Fusion 360 is to make a male "tool" body to cut female threads, and a male "tool" body to cut the female threads and use those tools to subtract out the material I don't want. Tweaking the threads is the "big trick", easiest explained by an example of making a threaded hole. I make the tool by creating a cylinder that fills the hole that will be threaded this is a new body in F360 lingo. Then I scale that body to 66.666% along the axis (make the plug shorter). Then I use F360 to apply standard threads to this body. Then I scale it again in along the axis, this time by 150%. Now it's the length of the original plug and the threads have been stretched so their thread angle is close to 45 degrees, an easy overhang. Last step is to do an F360 "combine", but cutting, not joining. Also, don't delete the tool bodies. The female threads in the hole are done. Now take the tool and scale it again, this time in the X and Y dimension. The scale factor depends on the the diameter of the plug. I shoot for a reduction of about .2mm per side, so maybe 98% might be typical. This scaling makes the male threads slightly smaller so they'll fit better. Now do another f360 combine, but joining to a stub on the male part. Done. I think it takes longer to write how to do it than doing it.