Axles move differently on a job

-

I adjusted my axles properly, but have now sent my first job.... here, with a square of 100 x 100 mm, only 40mm is driven, why is that?

-

At a guess, steps per mm is wrong.

-

@phaedrux but if I enter a movement via the dashboard, the dimensions are correct... only when I had a job printed was it wrong

-

@axiom said in Axles move differently on a job:

@phaedrux but if I enter a movement via the dashboard, the dimensions are correct... only when I had a job printed was it wrong

Then it's most likely something wrong with your slicer settings. Maybe the axis limits don't match the physical build area, maybe there is a scaling factor being applied, maybe a few hundred other possibilities but without more information, it's impossible to say.

-

@deckingman what information is interesting

-

@axiom said in Axles move differently on a job:

@deckingman what information is interesting

Everything that is in this thread https://forum.duet3d.com/topic/5909/guide-for-posting-requests-for-help

Plus what slicer you are using and all the slicer settings, including the machine configuration.

-

@deckingman

I tested the distance of movements of all axes with different G1 H2 commands via the console and also via the dashboard "buttons". Everything was correct.

However, if I send a file to be printed, the distance in the x-axis is only printed in 60mm instead of 100mm, but the y-distance is printed correctly.

I have the Ultimaker Cura as a slicer: Here is the G-codeFLAVOR:RepRap ;TIME:1078 ;Filament used: 0m, 0.809064m ;Layer height: 0.4 ;MINX:128.363 ;MINY:522.24 ;MINZ:0.6 ;MAXX:232.963 ;MAXY:626.84 ;MAXZ:5 ;Generated with Cura_SteamEngine 4.12.1 T1 M190 S120 M104 S230 M109 S230 M82 ;absolute extrusion mode G28 ;Home G1 Z15.0 F6000 ;Move the platform down 15mm ;Prime the extruder G92 E0 G1 F200 E3 G92 E0 M83 ;relative extrusion mode G1 F1500 E-6.5 ;LAYER_COUNT:12 ;LAYER:0 M107 G0 F3600 X129.622 Y522.323 Z0.6 ;TYPE:SKIRT G1 F1500 E6.5 G1 F600 X130.163 Y522.24 E0.06177 G1 X231.163 Y522.24 E11.3992 G1 X231.54 Y522.28 E0.04279 G1 X231.9 Y522.398 E0.04276 G1 X232.227 Y522.588 E0.04268 G1 X232.508 Y522.843 E0.04283 G1 X232.728 Y523.152 E0.04281 G1 X232.88 Y523.499 E0.04276 G1 X232.963 Y524.04 E0.06177 G1 X232.963 Y625.04 E11.3992 G1 X232.923 Y625.417 E0.04279 G1 X232.805 Y625.777 E0.04276 G1 X232.615 Y626.104 E0.04268 G1 X232.36 Y626.385 E0.04283 G1 X232.051 Y626.605 E0.04281 G1 X231.704 Y626.757 E0.04276 G1 X231.163 Y626.84 E0.06177 G1 X130.163 Y626.84 E11.3992 G1 X129.786 Y626.8 E0.04279 G1 X129.426 Y626.682 E0.04276 G1 X129.099 Y626.492 E0.04268 G1 X128.818 Y626.237 E0.04283 G1 X128.598 Y625.928 E0.04281 G1 X128.446 Y625.581 E0.04276 G1 X128.363 Y625.04 E0.06177 G1 X128.363 Y524.04 E11.3992 G1 X128.403 Y523.663 E0.04279 G1 X128.521 Y523.303 E0.04276 G1 X128.711 Y522.976 E0.04268 G1 X128.966 Y522.695 E0.04283 G1 X129.275 Y522.475 E0.04281 G1 X129.622 Y522.323 E0.04276 G0 F3600 X129.889 Y523.506 G1 F600 X130.163 Y523.44 E0.03181 G1 X231.163 Y523.44 E11.3992 G1 X231.378 Y523.48 E0.02468 G1 X231.564 Y523.593 E0.02456 G1 X231.697 Y523.766 E0.02463 G1 X231.763 Y524.04 E0.03181 G1 X231.763 Y625.04 E11.3992 G1 X231.723 Y625.255 E0.02468 G1 X231.61 Y625.441 E0.02456 G1 X231.437 Y625.574 E0.02463 G1 X231.163 Y625.64 E0.03181 G1 X130.163 Y625.64 E11.3992 G1 X129.948 Y625.6 E0.02468 G1 X129.762 Y625.487 E0.02456 G1 X129.629 Y625.314 E0.02463 G1 X129.563 Y625.04 E0.03181 G1 X129.563 Y524.04 E11.3992 G1 X129.603 Y523.825 E0.02468 G1 X129.716 Y523.639 E0.02456 G1 X129.889 Y523.506 E0.02463 G1 F1500 E-6.5 ;MESH:Quadrat_Test.stl G0 F3600 X131.993 Y525.87 G1 F1500 E6.5 G0 F3600 X132.063 Y525.94 ;TYPE:WALL-OUTER G1 F600 X132.063 Y623.14 E10.97032 G1 X229.263 Y623.14 E10.97032 G1 X229.263 Y525.94 E10.97032 G1 X132.063 Y525.94 E10.97032 G0 F3600 X132.063 Y526.54 G0 X131.963 Y526.54 G0 X132.035 Y623.168 G0 X229.993 Y623.87 G0 X230.063 Y623.94 G1 F600 X131.263 Y623.94 E10.51491 G1 X131.263 Y525.14 E10.51491 G1 X230.063 Y525.14 E10.51491 G1 X230.063 Y623.94 E10.51491 G0 F3600 X229.463 Y623.94 ;MESH:NONMESH G0 F600 X229.463 Y623.94 Z1 G0 F3600 X229.463 Y623.84 G0 X132.035 Y623.168 G0 X131.993 Y525.87 G0 X132.063 Y525.94 ;TIME_ELAPSED:178.853758 ;LAYER:1 M106 S255 ;TYPE:WALL-OUTER ;MESH:Quadrat_Test.stl G1 F600 X132.063 Y623.14 E7.31354 G1 X229.263 Y623.14 E7.31354 G1 X229.263 Y525.94 E7.31354 G1 X132.063 Y525.94 E7.31354 G0 F5400 X132.063 Y526.54 G0 X131.963 Y526.54 G0 X132.035 Y623.168 G0 X229.993 Y623.87 G0 X230.063 Y623.94 G1 F600 X131.263 Y623.94 E7.00994 G1 X131.263 Y525.14 E7.00994 G1 X230.063 Y525.14 E7.00994 G1 X230.063 Y623.94 E7.00994 G0 F5400 X229.463 Y623.94 ;MESH:NONMESH G0 F600 X229.463 Y623.94 Z1.4 G0 F5400 X229.463 Y623.84 G0 X132.035 Y623.168 G0 X131.993 Y525.87 G0 X132.063 Y525.94 ;TIME_ELAPSED:261.806833 ;LAYER:2 ;TYPE:WALL-OUTER ;MESH:Quadrat_Test.stl G1 F600 X132.063 Y623.14 E7.31354 G1 X229.263 Y623.14 E7.31354 G1 X229.263 Y525.94 E7.31354 G1 X132.063 Y525.94 E7.31354 G0 F7200 X132.063 Y526.54 G0 X131.963 Y526.54 G0 X132.035 Y623.168 G0 X229.993 Y623.87 G0 X230.063 Y623.94 G1 F600 X131.263 Y623.94 E7.00994 G1 X131.263 Y525.14 E7.00994 G1 X230.063 Y525.14 E7.00994 G1 X230.063 Y623.94 E7.00994 G0 F7200 X229.463 Y623.94 ;MESH:NONMESH G0 F600 X229.463 Y623.94 Z1.8 G0 F7200 X229.463 Y623.84 G0 X132.035 Y623.168 G0 X131.993 Y525.87 G0 X132.063 Y525.94 ;TIME_ELAPSED:343.702935 ;LAYER:3 ;TYPE:WALL-OUTER ;MESH:Quadrat_Test.stl G1 F600 X132.063 Y623.14 E7.31354 G1 X229.263 Y623.14 E7.31354 G1 X229.263 Y525.94 E7.31354 G1 X132.063 Y525.94 E7.31354 G0 F7200 X132.063 Y526.54 G0 X131.963 Y526.54 G0 X132.035 Y623.168 G0 X229.993 Y623.87 G0 X230.063 Y623.94 G1 F600 X131.263 Y623.94 E7.00994 G1 X131.263 Y525.14 E7.00994 G1 X230.063 Y525.14 E7.00994 G1 X230.063 Y623.94 E7.00994 G0 F7200 X229.463 Y623.94 ;MESH:NONMESH G0 F600 X229.463 Y623.94 Z2.2 G0 F7200 X229.463 Y623.84 G0 X132.035 Y623.168 G0 X131.993 Y525.87 G0 X132.063 Y525.94 ;TIME_ELAPSED:425.599036 ;LAYER:4 ;TYPE:WALL-OUTER ;MESH:Quadrat_Test.stl G1 F600 X132.063 Y623.14 E7.31354 G1 X229.263 Y623.14 E7.31354 G1 X229.263 Y525.94 E7.31354 G1 X132.063 Y525.94 E7.31354 G0 F7200 X132.063 Y526.54 G0 X131.963 Y526.54 G0 X132.035 Y623.168 G0 X229.993 Y623.87 G0 X230.063 Y623.94 G1 F600 X131.263 Y623.94 E7.00994 G1 X131.263 Y525.14 E7.00994 G1 X230.063 Y525.14 E7.00994 G1 X230.063 Y623.94 E7.00994 G0 F7200 X229.463 Y623.94 ;MESH:NONMESH G0 F600 X229.463 Y623.94 Z2.6 G0 F7200 X229.463 Y623.84 G0 X132.035 Y623.168 G0 X131.993 Y525.87 G0 X132.063 Y525.94 ;TIME_ELAPSED:507.495138 ;LAYER:5 ;TYPE:WALL-OUTER ;MESH:Quadrat_Test.stl G1 F600 X132.063 Y623.14 E7.31354 G1 X229.263 Y623.14 E7.31354 G1 X229.263 Y525.94 E7.31354 G1 X132.063 Y525.94 E7.31354 G0 F7200 X132.063 Y526.54 G0 X131.963 Y526.54 G0 X132.035 Y623.168 G0 X229.993 Y623.87 G0 X230.063 Y623.94 G1 F600 X131.263 Y623.94 E7.00994 G1 X131.263 Y525.14 E7.00994 G1 X230.063 Y525.14 E7.00994 G1 X230.063 Y623.94 E7.00994 G0 F7200 X229.463 Y623.94 ;MESH:NONMESH G0 F600 X229.463 Y623.94 Z3 G0 F7200 X229.463 Y623.84 G0 X132.035 Y623.168 G0 X131.993 Y525.87 G0 X132.063 Y525.94 ;TIME_ELAPSED:589.391240 ;LAYER:6 ;TYPE:WALL-OUTER ;MESH:Quadrat_Test.stl G1 F600 X132.063 Y623.14 E7.31354 G1 X229.263 Y623.14 E7.31354 G1 X229.263 Y525.94 E7.31354 G1 X132.063 Y525.94 E7.31354 G0 F7200 X132.063 Y526.54 G0 X131.963 Y526.54 G0 X132.035 Y623.168 G0 X229.993 Y623.87 G0 X230.063 Y623.94 G1 F600 X131.263 Y623.94 E7.00994 G1 X131.263 Y525.14 E7.00994 G1 X230.063 Y525.14 E7.00994 G1 X230.063 Y623.94 E7.00994 G0 F7200 X229.463 Y623.94 ;MESH:NONMESH G0 F600 X229.463 Y623.94 Z3.4 G0 F7200 X229.463 Y623.84 G0 X132.035 Y623.168 G0 X131.993 Y525.87 G0 X132.063 Y525.94 ;TIME_ELAPSED:671.287341 ;LAYER:7 ;TYPE:WALL-OUTER ;MESH:Quadrat_Test.stl G1 F600 X132.063 Y623.14 E7.31354 G1 X229.263 Y623.14 E7.31354 G1 X229.263 Y525.94 E7.31354 G1 X132.063 Y525.94 E7.31354 G0 F7200 X132.063 Y526.54 G0 X131.963 Y526.54 G0 X132.035 Y623.168 G0 X229.993 Y623.87 G0 X230.063 Y623.94 G1 F600 X131.263 Y623.94 E7.00994 G1 X131.263 Y525.14 E7.00994 G1 X230.063 Y525.14 E7.00994 G1 X230.063 Y623.94 E7.00994 G0 F7200 X229.463 Y623.94 ;MESH:NONMESH G0 F600 X229.463 Y623.94 Z3.8 G0 F7200 X229.463 Y623.84 G0 X132.035 Y623.168 G0 X131.993 Y525.87 G0 X132.063 Y525.94 ;TIME_ELAPSED:753.183443 ;LAYER:8 ;TYPE:WALL-OUTER ;MESH:Quadrat_Test.stl G1 F600 X132.063 Y623.14 E7.31354 G1 X229.263 Y623.14 E7.31354 G1 X229.263 Y525.94 E7.31354 G1 X132.063 Y525.94 E7.31354 G0 F7200 X132.063 Y526.54 G0 X131.963 Y526.54 G0 X132.035 Y623.168 G0 X229.993 Y623.87 G0 X230.063 Y623.94 G1 F600 X131.263 Y623.94 E7.00994 G1 X131.263 Y525.14 E7.00994 G1 X230.063 Y525.14 E7.00994 G1 X230.063 Y623.94 E7.00994 G0 F7200 X229.463 Y623.94 ;MESH:NONMESH G0 F600 X229.463 Y623.94 Z4.2 G0 F7200 X229.463 Y623.84 G0 X132.035 Y623.168 G0 X131.993 Y525.87 G0 X132.063 Y525.94 ;TIME_ELAPSED:835.079545 ;LAYER:9 ;TYPE:WALL-OUTER ;MESH:Quadrat_Test.stl G1 F600 X132.063 Y623.14 E7.31354 G1 X229.263 Y623.14 E7.31354 G1 X229.263 Y525.94 E7.31354 G1 X132.063 Y525.94 E7.31354 G0 F7200 X132.063 Y526.54 G0 X131.963 Y526.54 G0 X132.035 Y623.168 G0 X229.993 Y623.87 G0 X230.063 Y623.94 G1 F600 X131.263 Y623.94 E7.00994 G1 X131.263 Y525.14 E7.00994 G1 X230.063 Y525.14 E7.00994 G1 X230.063 Y623.94 E7.00994 G0 F7200 X229.463 Y623.94 ;MESH:NONMESH G0 F600 X229.463 Y623.94 Z4.6 G0 F7200 X229.463 Y623.84 G0 X132.035 Y623.168 G0 X131.993 Y525.87 G0 X132.063 Y525.94 ;TIME_ELAPSED:916.975647 ;LAYER:10 ;TYPE:WALL-OUTER ;MESH:Quadrat_Test.stl G1 F600 X132.063 Y623.14 E7.31354 G1 X229.263 Y623.14 E7.31354 G1 X229.263 Y525.94 E7.31354 G1 X132.063 Y525.94 E7.31354 G0 F7200 X132.063 Y526.54 G0 X131.963 Y526.54 G0 X132.035 Y623.168 G0 X229.993 Y623.87 G0 X230.063 Y623.94 G1 F600 X131.263 Y623.94 E7.00994 G1 X131.263 Y525.14 E7.00994 G1 X230.063 Y525.14 E7.00994 G1 X230.063 Y623.94 E7.00994 G0 F7200 X229.463 Y623.94 ;MESH:NONMESH G0 F600 X229.463 Y623.94 Z5 G0 F7200 X229.463 Y623.84 G0 X132.035 Y623.168 G0 X131.993 Y525.87 G0 X132.063 Y525.94 ;TIME_ELAPSED:998.871748 ;LAYER:11 ;TYPE:WALL-OUTER ;MESH:Quadrat_Test.stl G1 F600 X132.063 Y623.14 E7.31354 G1 X229.263 Y623.14 E7.31354 G1 X229.263 Y525.94 E7.31354 G1 X132.063 Y525.94 E7.31354 G0 F7200 X132.063 Y526.54 G0 X131.963 Y526.54 G0 X132.035 Y623.168 G0 X229.993 Y623.87 G0 X230.063 Y623.94 G1 F600 X131.263 Y623.94 E7.00994 G1 X131.263 Y525.14 E7.00994 G1 X230.063 Y525.14 E7.00994 G1 X230.063 Y623.94 E7.00994 G0 F7200 X229.463 Y623.94 ;TIME_ELAPSED:1078.991624 G1 F1500 E-6.5 M140 S0 M82 ;absolute extrusion mode M107 M104 S0 M140 S0 ;Retract the filament G92 E1 G1 E-1 F300 G28 X0 Y0 M84 M83 ;relative extrusion mode M104 S0 ;End of Gcode ;SETTING_3 {"global_quality": "[general]\\nversion = 4\\nname = PLA 1.2\\ndefini ;SETTING_3 tion = custom\\n\\n[metadata]\\ntype = quality_changes\\nquality_type ;SETTING_3 = coarse\\nsetting_version = 19\\n\\n[values]\\nadhesion_type = brim ;SETTING_3 \\nlayer_height_0 = 0.6\\nmaterial_bed_temperature = 120\\nsupport_en ;SETTING_3 able = False\\n\\n", "extruder_quality": ["[general]\\nversion = 4\\n ;SETTING_3 name = PLA 1.2\\ndefinition = custom\\n\\n[metadata]\\ntype = quality ;SETTING_3 _changes\\nquality_type = not_supported\\nintent_category = default\\ ;SETTING_3 nposition = 0\\nsetting_version = 19\\n\\n[values]\\ninfill_pattern = ;SETTING_3 trihexagon\\ninfill_sparse_density = 60\\nmaterial_final_print_tempe ;SETTING_3 rature = 215\\nmaterial_initial_print_temperature = 215\\nmaterial_pr ;SETTING_3 int_temperature = 220\\nspeed_print = 40\\ntop_bottom_thickness = 1.2 ;SETTING_3 \\nwall_thickness = 1.2\\n\\n", "[general]\\nversion = 4\\nname = PLA ;SETTING_3 1.2\\ndefinition = custom\\n\\n[metadata]\\ntype = quality_changes\\ ;SETTING_3 nquality_type = coarse\\nintent_category = default\\nposition = 1\\ns ;SETTING_3 etting_version = 19\\n\\n[values]\\nbrim_gap = 0.5\\nbrim_width = 2\\ ;SETTING_3 ninfill_sparse_density = 60\\nmaterial_final_print_temperature = 230\ ;SETTING_3 \nmaterial_initial_print_temperature = 230\\nmaterial_print_temperatu ;SETTING_3 re = 230\\nspeed_print = 20\\nwall_thickness = 1.2\\n\\n"]}And Here my config.g

; Configuration file for Duet WiFi (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.12 on Wed Aug 24 2022 12:56:11 GMT+0200 (Mitteleuropäische Sommerzeit) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"DUKA1300" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P1 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S0 ; physical drive 2 goes forwards M569 P3 S0 ; physical drive 3 goes forwards extruder1 M569 P4 S1 ; physical drive 4 goes forwards M584 X0 Y1 Z2 E3:4 ; set drive mapping M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation ;M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm M92 X80.00 Y80.00 Z640.00 E320.20:320.51 ; set steps per mm M566 X900.00 Y900.00 Z120.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z1200.00 E1200.00:1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z40.00 E250.00:250.00 ; set accelerations (mm/s^2) M906 X1800 Y1800 Z2000 E1800:1800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X125 Y45 Z0 S1 ; set axis minima M208 X715 Y815 Z1200 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop ;M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop ;M574 Z2 S2 ; configure Z-probe endstop for high end on Z ; Z-Probe M558 P1 C"!zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds G31 P1000 X-20 Y80 Z1.788 ; set Z probe trigger value, offset and trigger height M557 X125:710Y45:810S100 ; define mesh grid ; Heaters M308 S0 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin e1temp M950 H0 C"e1heat" T0 ; create nozzle heater output on e1heat and map it to sensor 0 M307 H0 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit M143 H0 S250 ; set temperature limit for heater 0 to 250C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit M143 H1 S250 ; set temperature limit for heater 1 to 250C M308 S2 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin bedtemp M950 H2 C"bedheat" T2 ; create bed heater output on bedheat and map it to sensor 2 M307 H2 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit M140 H2 ; map heated bed to heater 2 M143 H2 S280 ; set temperature limit for heater 2 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency ;M106 P0 S1 H0 T45 ; set fan 0 value. Thermostatic control is turned on M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency ;M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H0 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M563 P1 D1 H1 F1 ; define tool 1 G10 P1 X45 Y45 Z0 ; set tool 1 axis offsets G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@axiom said in Axles move differently on a job:

What happens if you send........(Make sure the printer is homed first).

G1 X231

Then send

G1 X130

Those are two X axis moves from your gcode file rounded down. What should happen is that the print head should move to a position 231mm in the X direction from your origin after the first move, then it should move to a position 130mm in the X direction from your origin. The distance between the 2 positions should be 101mm.

-

What does your machine setup look like in Cura?

Your T1 definition has some offsets. Is the tool unable to reach all printable areas on the bed?

-

-

the bed is huge (this is also visible in my config.g). what surprises me about cura's gcode is that it enters the min and max values of the axes incorrectly, even though i specified this in cura in the machine configuration. I also set REPRAP in cura. Are there any conversion problems known? Is there better experience with Prusa Slicer or other slicers?

-

@axiom said in Axles move differently on a job:

cura's gcode is that it enters the min and max values of the axes incorrectly

You mean this?

;MINX:128.363 ;MINY:522.24 ;MINZ:0.6 ;MAXX:232.963 ;MAXY:626.84 ;MAXZ:5I think that's just the area of the sliced object, no? At any rate those aren't actual commands for the Duet so will have no effect.

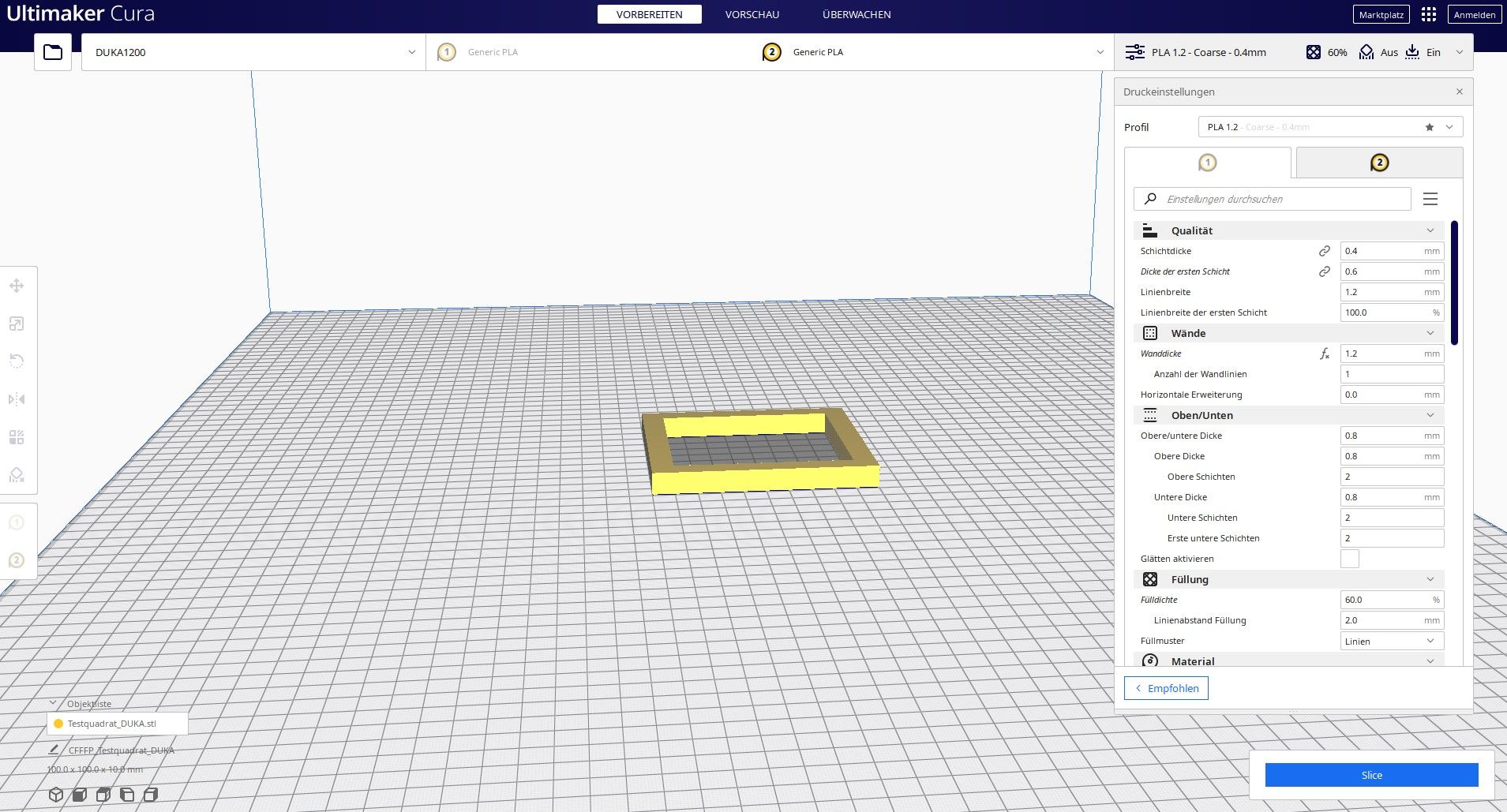

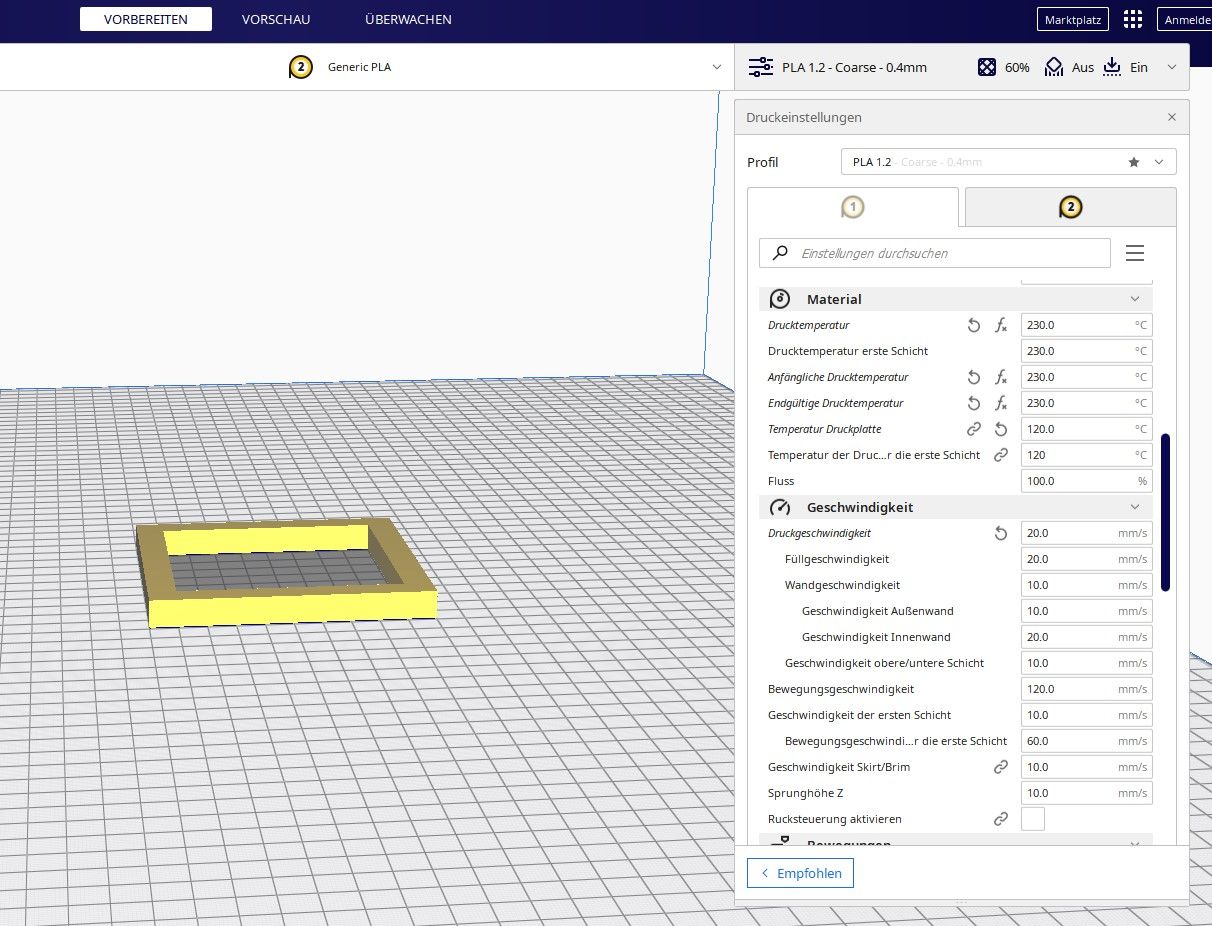

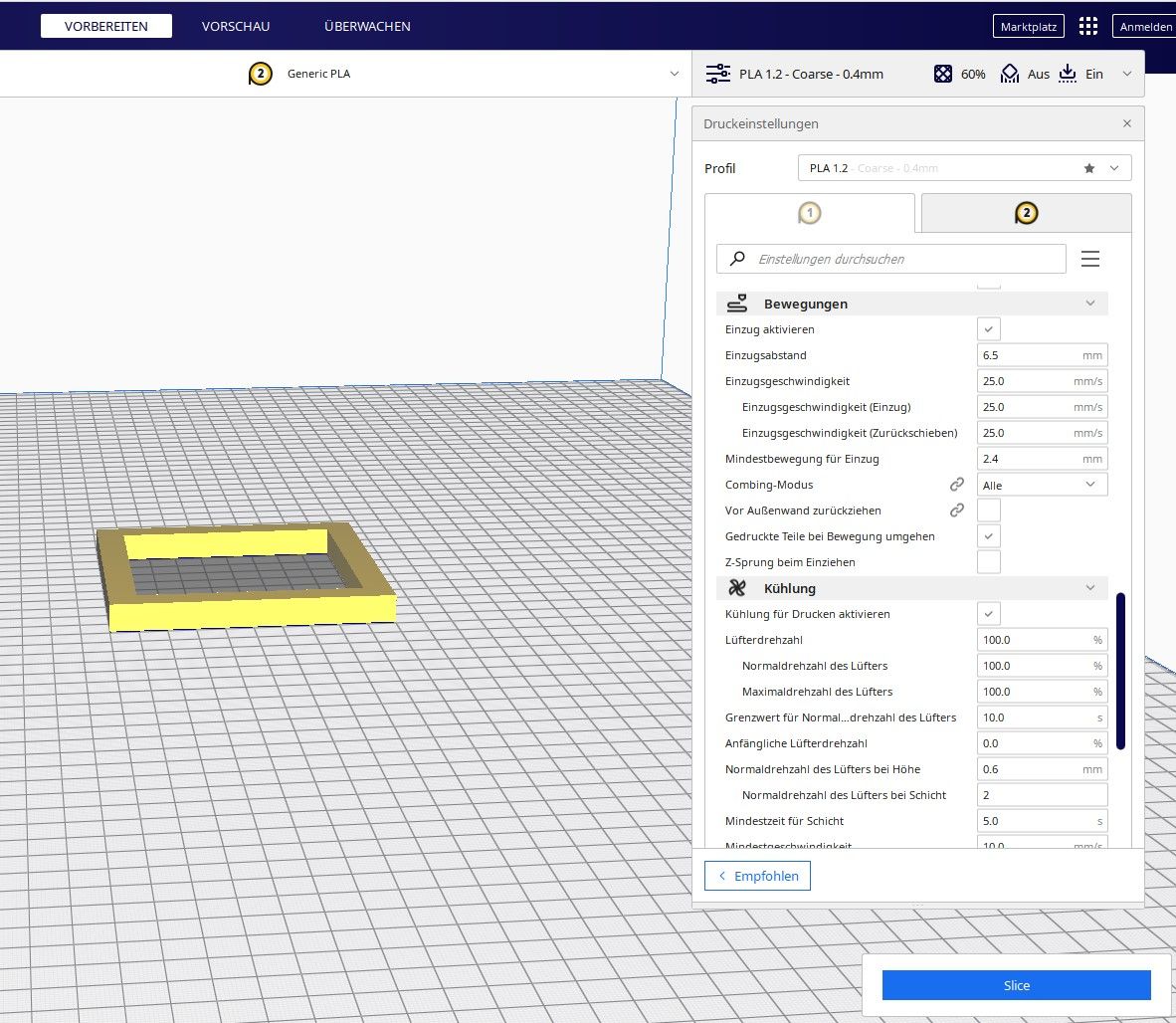

Can you share some screen shots of your Cura machine settings?

-

@axiom said in Axles move differently on a job:

@deckingman said in Axles move differently on a job:

G1 X130

he passes this test exactly

So you can send the exact same X axis travel commands that are in your sliced gcode and the movement is as expected at 100mm. But you claim that when you print that gcode file, containing the same commands, the X axis only moves 60mm. I have no idea what could cause that.

-

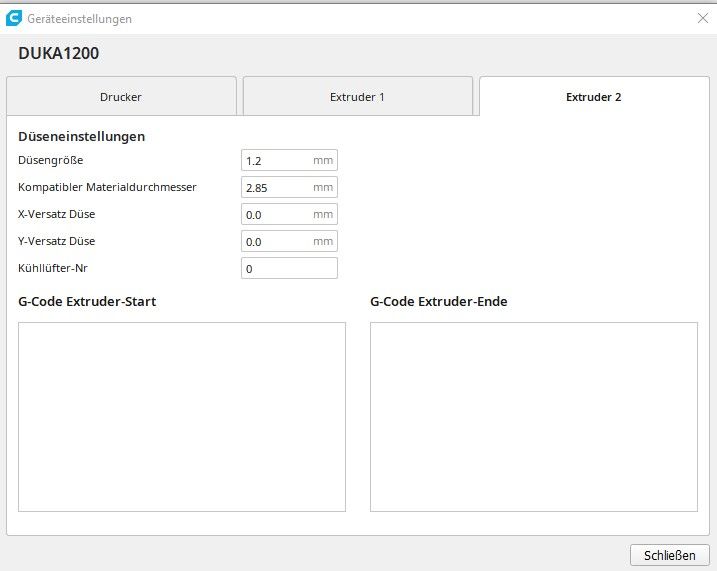

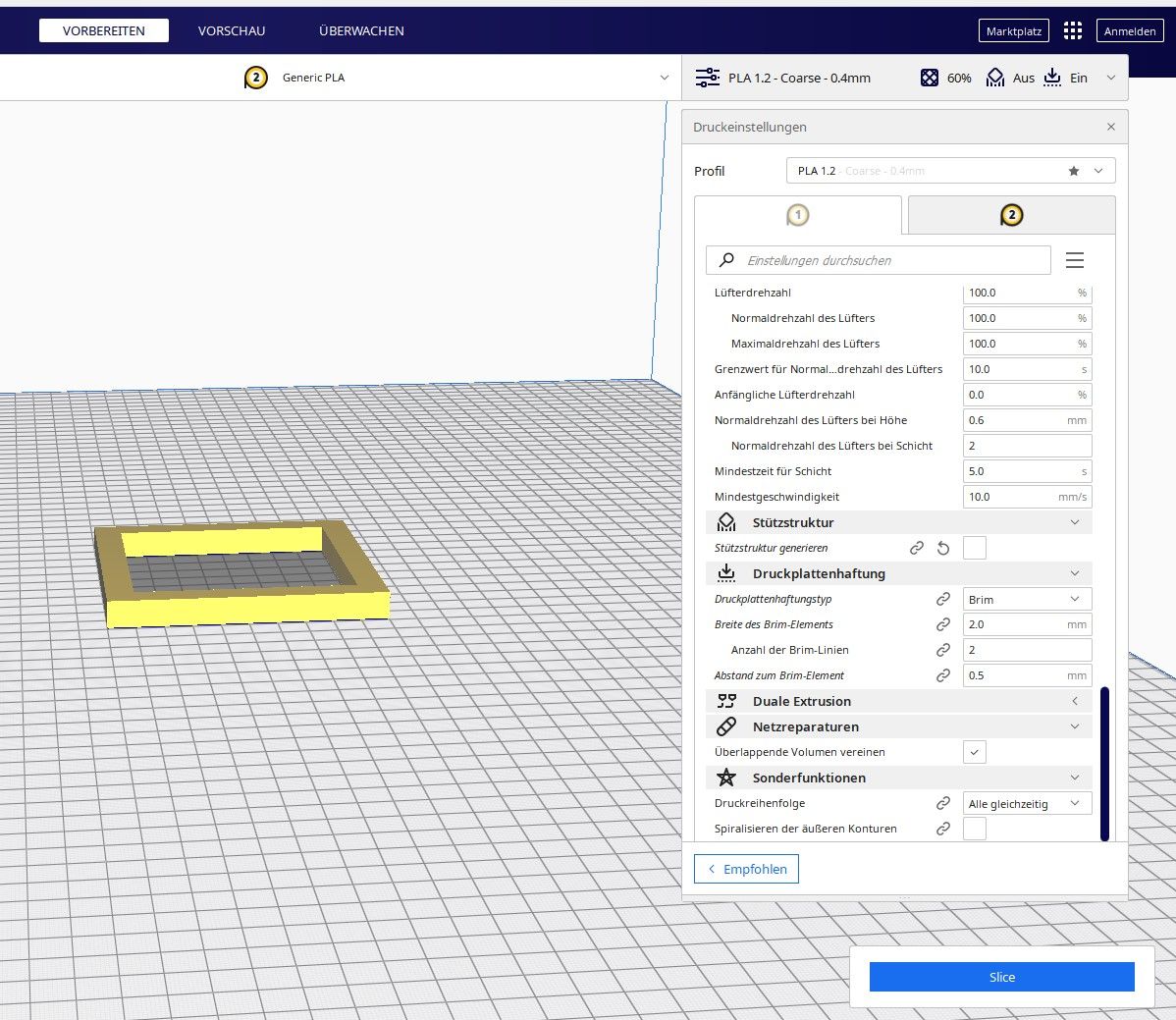

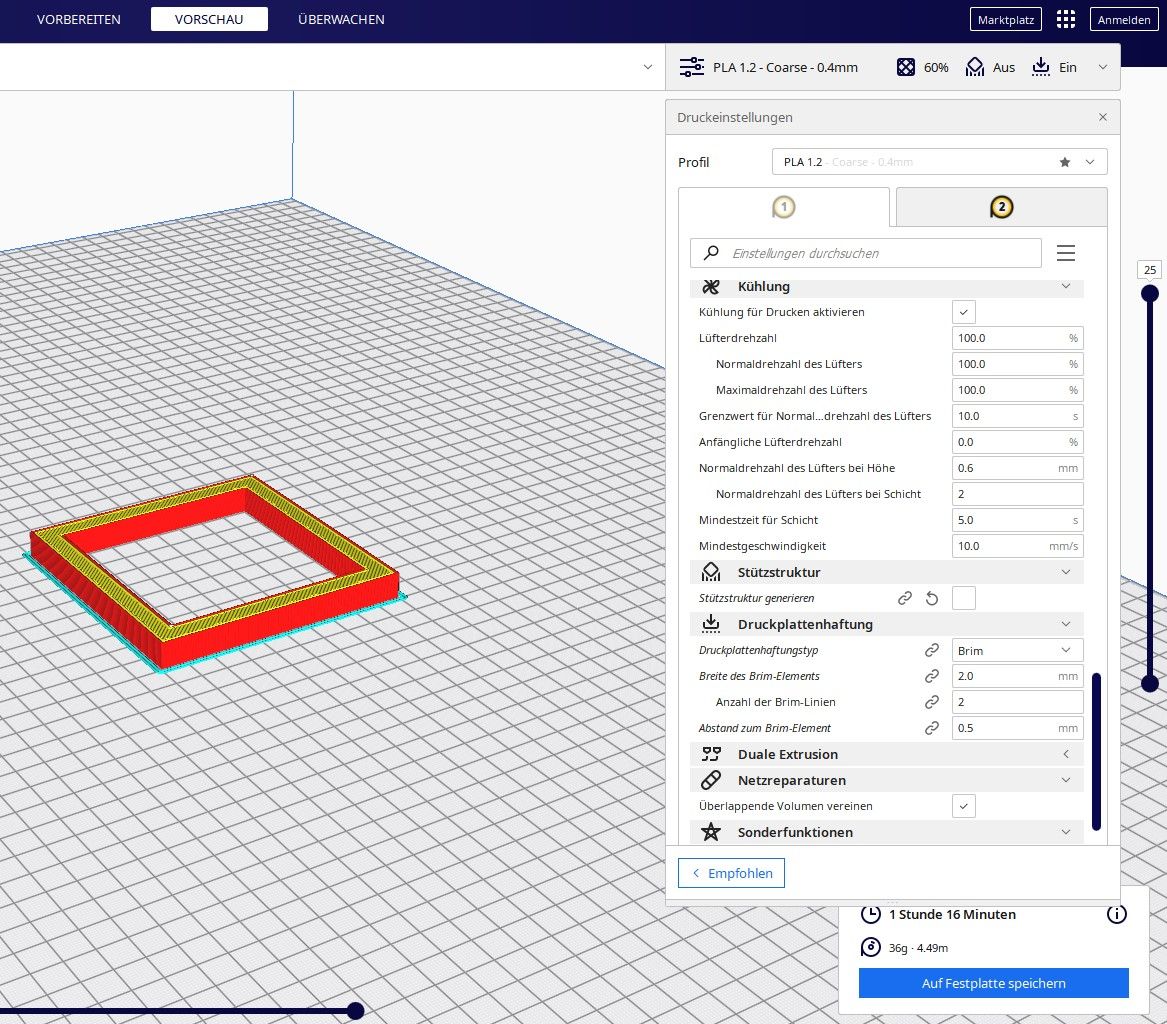

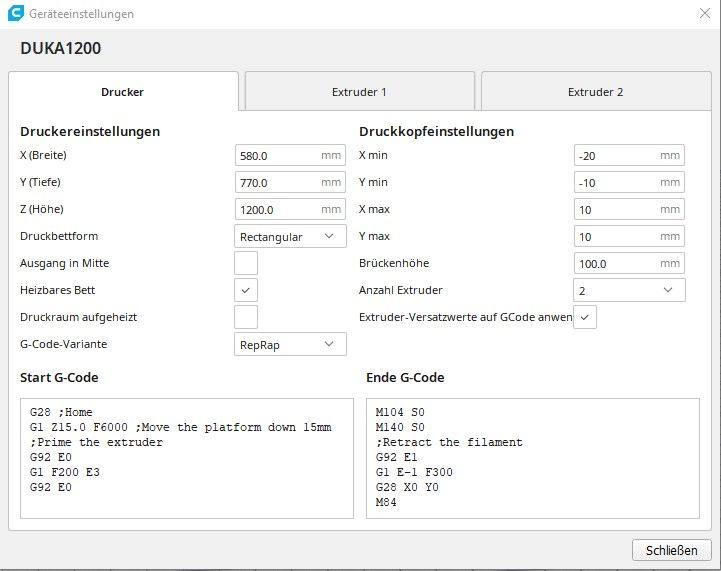

@phaedrux !

the settings are not very spectacular. I created a custom printer with the fantasy name DUKA1200. I deactivated extruder 1 because I only want to work with one extruder for the time being. The second extruder does exist on the machine, but I won't test it until next year at the earliest. -

-

Can you post your homing files?

Have you tried another slicer yet? PrusaSlicer perhaps? -

@phaedrux Sorry, i don´t understand "homing files". I didnt try another slicer yet...but i will try

-

Homing files are the homex.g homey.g homez.g homeall.g files located in the system tab in DWC. They are the macros executed when you home an axis. They dictate how the homing will proceed.