Are these parts suitable for this 3D printer design?

-

@deckingman

Hi sir. thank you.

I think I have to read all the messages again. Since English is not my native language, I am translating my questions and answers with the help of Google. And because in some places Google does not do this translation well, I may not understand some sentences well. -

@deckingman

hello. sir i have a few more questions.

if we use BLTouch and connect it to Zmin, There is no need to use mechanical endstops for the zmin axix?

And usually 3 end-stops ( 2 mechanical for x and y and one bltouch for z min) are enough for xycore pritners?I saw a video on YouTube saying that "Power less Recovery feature" in Marlin program may not work well for xycore printers. Thanks to your advice, I realized that if I use a 2 mm lead screw, the bed will not fall. The point is that if the bed does not fall, it is easy to use the power less recovery function in the Marlin program without any problem?

thanks.

-

@mahmoudz Yes to all of that.

-

@deckingman

Thanks alot sir.

You have taught me many things during this time.

Thank you very much.. -

@deckingman

Hi sir. I saw on the internet that some people use a system called V-slot wheels instead of using rails and wagons in 3D printers.

Is it worth using this system in the axes of the 3D printer, or will the wheels break down and wear out very quickly? Can you please guide me regarding the friction and life of these wheels and if these wheels are good, which model should I get? (because I realized that these wheels have different materials)

Thanks alot

-

Anybody using successfully resume after power cut?

Never tried it and am not sure how that work, considering the model cooling/heating cycle, and the lack of rehoming.

I wonder if a UPS would be a more effective solution, to avoid the power cut in the first place, even if just to the steppers if not to the heaters.

-

@mahmoudz said in Are these parts suitable for this 3D printer design?:

@deckingman

Hi sir. I saw on the internet that some people use a system called V-slot wheels instead of using rails and wagons in 3D printers.

Is it worth using this system in the axes of the 3D printer, or will the wheels break down and wear out very quickly? Can you please guide me regarding the friction and life of these wheels and if these wheels are good, which model should I get? (because I realized that these wheels have different materials)

Thanks alot

I built my printer entirely from Open Builds V-slot rails and wheels about 6years ago. Since then, it has run for thousands of hours without any problems related to the wheels and guides. I use a heavy mulit-input hot ends so have a moving mass in the Y direction of up to 3Kgs which is very high by most peoples standards, and my default travel speed is 350mm/sec which is also high by many peoples standards. Here is a video of how it looked 3 years ago with a 5 input Diamond hot end. Much has changed since then but the basic rails and wheels remain the same. https://www.youtube.com/watch?v=IG3AGKDzdH4

There are many more videos on my YouTube channel and writes ups in my blog - both of which are linked to in my signature below.

As you'll see from the video, I made many of my own aluminium parts for things like motor mounts but you can buy kits from the likes of RatRig and others - e.g. https://ratrig.com/3d-printing-cnc/3d-printer-kits/all-3d-printer-kits/v-core3configurable.html

My advice would be to use Open Builds solid or Delrin Wheels - not the Mini or Extreme versions. https://openbuildspartstore.com/wheels/

Pay particular attention to how you assemble them - use the Open Builds guides. e.g. https://www.youtube.com/watch?v=pMtHy7sDNG4. Most problems that people have had is because they haven't assembled the wheels correctly. The most common mistake is setting the eccentric spacer too tight. The next most common problem is forgetting to fit the precision spacer between the two bearings or over-tightening the lock nut. Any of these mistakes will prevent the wheel from rotating freely causing excessive wear.

-

@zapta said in Are these parts suitable for this 3D printer design?:

Anybody using successfully resume after power cut?

Never tried it and am not sure how that work, considering the model cooling/heating cycle, and the lack of rehoming.

I wonder if a UPS would be a more effective solution, to avoid the power cut in the first place, even if just to the steppers if not to the heaters.

I did exactly that (fit a UPS). In my case, I chose to use a 24V DC UPS mostly because it seemed a bit daft to convert from a DC battery to AC mains then have the power supply convert the AC mains back down to 24V DC. Doing it that way loses some run time capacity because the conversion process is not 100% efficient. I have two 12V batteries in series giving me 24V. They are only about 20Ahr IIRC, but they will run the printer for many hours. Having said that, the mains powered bed does not get power when running off the batteries. But it's a big 400mm x 400mm x 12mm aluminium plate with 12mm of semi-rigid insulation underneath, so it take a very long time to cool sufficiently for the part to become detached.

Here is more detailed explanation that I wrote up on my blog which has a link to video showing it in action. https://somei3deas.wordpress.com/2019/10/22/fitting-a-dc-uninterruptible-power-supply-ups-and-separate-5v-supply/

-

@deckingman

Thank you very much. That’s very kind.

-

here a few time for you as some have say , ive designed and built my printer it used 8mm screw for the bed first , but the screww what bending under the weight of heated bed , replaced it by belt than had the problem of bed goign down on power off , i fixed that problem by changing a few pulley , i have 20>60-20>60-20 for reduction , even when power is off bed stay were it is , it doesnt drop . it is powered in my vace by 2 60mm nema 17,

like many said , it is better to have a light head that move in the X-Y axis than having a heavy bed that move on y or X , bed should only go up or down . think about your design maybe a bit more . other things you should look into is to use 12mm belt for axis not 6mm , 6mm will act like spring in those dimension , my printer started with 6mm belt now it all 12mm and it fixed many of the issue i had with 6mm

-

@Dad003

Thank you -

@mahmoudz

Hello Sir. How are you?

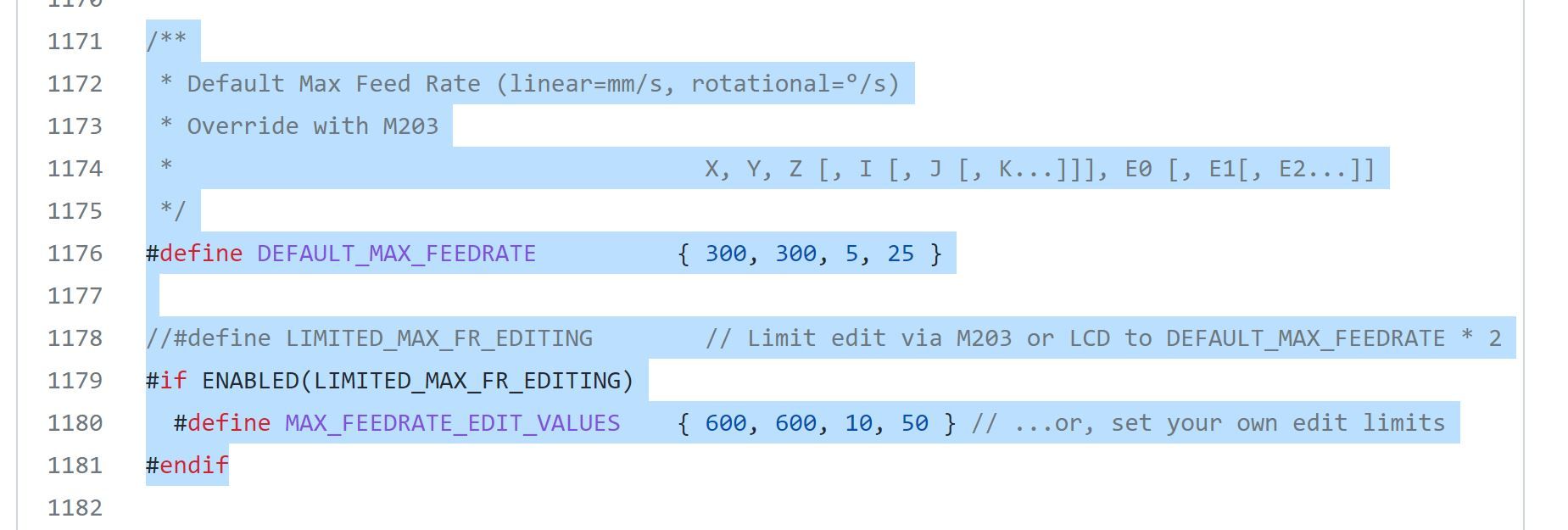

Sir do you know what is "max feedrate" in marlin? how these “max federate” numbers are calculated?I checked the Marlin examples folder and checked different models of printers and each of them included unique settings for “.And because of the uniqueness of these numbers in different printers, I guessed that this section must be very important because different printers use unique numbers.

I did a lot of searching on a topic in Hypercube printers and I couldn't find the answer for how to calculate max feedrate. I even asked this question in Facebook groups and I still haven't found the answer. also, On Marlin's website, there is not much information about this issue.

And forgive me for asking you so many questions during this time. I really search for topics first, and if the topic is unclear, I come and ask questions in forums and groups. thanks a lot for your help.

Unfortunately, malin website does not explain how the numbers should be calculated.

(And even the numbers in the Marlin firmware are not the same as the numbers in the Marlin manual.).

-

@mahmoudz max_ feed_ rate is just another way of saying "maximum speed". "Feedrate", "feed rate", "speed", and "velocity" are all the same thing - hence the units are distance per unit time - i.e. mm/sec, or mm/minute, if you are in a car, the kph (kilometres per hour).

Think of it as a speed limit. The firmware will limit the speed of any axis to whatever you set the maximum feed rate to. So if you tried to move an axis at a crazy high speed, the maximum feed rate would prevent that. You would normally set it to correspond to the speed where the stepper motor torque started to drop significantly. For "normal" printing, you are unlikely to reach those sort of speeds. If you set it too low, it will limit the maximum speed that you can print at. To give you rough idea, I do non-print moves at 350mm/sec ad don't want my 3kgs of moving mass to go any faster than that, so I set my maximum feed rate to 21,000 mm/minute which equates to 350mm/sec.

The RepRap equivalent of the Marlin command is is M203. https://docs.duet3d.com/User_manual/Reference/Gcodes#m203-set-maximum-feedrate

-

@deckingman

Thanks alot.

I understand it. Basically, the actual speed is set by the slicer and we include a limit for that speed so that the speed does not exceed that value. it's true?

And the following 4 numbers (300,300,5,25) mean for X, Y, Z and extruder?

And in addition to the extruder, this maximum speed should be defined for other triple axes (X,Y,Z) as well (Basically, here it is meant to limit the speed of the motors for the other three axes)?

Thank you very much for your help. That’s very kind.

-

@mahmoudz said in Are these parts suitable for this 3D printer design?:

Basically, the actual speed is set by the slicer and we include a limit for that speed so that the speed does not exceed that value. it's true?

Yes. That's correct.

-

@cosmowave

thanks alot.

-

@mahmoudz Yes to all of that. Also, bear in mind that a normal print move would be in the form G1 Xn Yn En and that for this purpose, the extruder (E) is treated just like an axis. For that G1 move, each axis move (including the extruder) must start and end at the same time. So if any one of those axes reached the maximum feed rate threshold, then all the other axes will also be limited, even though they might be running slower than their individual maximum feed rate values.

-

@deckingman

Thank you very much for your help. Actually, I learned a lot of good

Thanks alot

-

@mahmoudz For future reference, the Duet range of products run RepRap firmware and not Marlin. The two are very similar to each other but there are differences. You'll find that the documentation for RepRap firmware often has better descriptions of what each command does and how best to implement them.