Are these parts suitable for this 3D printer design?

-

@mahmoudz There is no negative mass alloy (upsidaisium?) that can make a 500x500 mm bed light enough to not be a problem when the machine is throwing it back and forth at print speed. If you must use that type of architecture, plan on keeping acceleration, jerk, and speed low, which is very undesirable when you're printing large objects because low speed greatly increases print time.

There are ways to prevent bed drop upon power loss in machine with a heavy Z axis. I previously linked a geared motor that I used in my printer that completely stops the bed from moving when motor power is cut. It can resume prints after power loss with minimal print defects (the bed may move slightly in Z- maybe 10-20 microns- when power is reapplied because the motor may jump). Other people use fine pitch screws to lift the bed which will often prevent the bed from dropping. Others use electrical brakes fitted to the Z axis motor(s). Some opt for counterweights or springs. I have not used those methods so I can't say how well they work.

There are other considerations when you want to resume a print after power loss. In most printers the bed is heated to help ensure that the print remains stuck to the bed throughout the print time. When power is lost for a long time, the bed may cool off and the print may let go of the bed. In that case, resuming the print may not be possible. Also, the bed expands when heated. You need to use a kinematic mount that will ensure that the bed/print returns to the correct XY position when the bed heats back up. A 500 mm aluminum bed will expand about 12 um per degree C. If you heat it to 70C (45C above an ambient 25C) for printing PETG, for example, it will expand by over 0.5 mm.

A NEMA-17 motor will not be able to drive a heavy Y axis at any reasonable speed. You will need a larger, higher torque motor (and maybe a driver to go with it). You can get 10mm wide belts that will stretch less than 6 mm wide belts, and you can get steel core belts that stretch less than glass core belts. If you use steel core belts you need to use large pulleys or the steel wires in the belt will break and cause all sorts of mysterious print quality problems. You can reduce belt springiness, but that won't eliminate the problem because the motor acts like a spring, too.

"Footprint" is the space the printer takes up on the floor. A machine with the bed moving in Y has to have a footprint at least 2x the size of the bed. Besides the space required, it adds a lot to the cost of the frame and enclosure (if you use one). That is why you don't see many large format printers with the bed moving in Y.

If you use two motors to lift the Z axis you will need to use some auto leveling because when the motors are powered up they will jump, and not necessarily by the same amount and same direction. That will tilt the X axis (or bed if you move the bed in Z). You can add a bed sensor and do some active autoleveling to prevent problems, or use a simpler approach by driving all Z axis screws/belts with a single motor which will prevent the X axis/bed from tilting when power is cycled.

It will be hard to get a 500x500 mm bed that is flat enough to print on without some active unflatness compensation, so you're going to need that bed sensor to be mounted on the extruder carriage anyway, so it can be used for leveling and unflatness compensation.

-

@mahmoudz In addition to what @mrehorstdmd has said, I must agree that having bed moving in the X or Y direction is a very bad idea - and with a bed as large as yours, it's a very bad idea for all the reasons that Mark said. Even if you did manage to overcome those obstacles and have a rigid enough frame that will keep the bed level as it moves, and a powerful enough motor or motors, you run the risk of the entire machine walking across the room like an out of balance washing machine.

I can only urge you to reconsider and move the print head in X and Y and limit the bed to moving in Z only. Alternatively, you could move the print head in X, Y and Z although that is more complicated to do, but it would still be preferable. -

@mahmoudz have a look at Ivan Miranda on YouTube. He has built large printers that move the bed in Y, but is currently building an even larger printer that has bed moving in Z.

There is always one axis moving in Z, so some drop on power loss is always expected. Usually the recovery is homing the axes, which you can do for Z at the maximum end of the axis, to avoid hitting the print on the other axes. If power loss is an issue, get an Uninterruptible Power Supply. Recovering from power loss on any machine is never completely straightforward, and usually causes a seam on the printed part, so avoiding it in the first place is the best option.

Ian

-

@droftarts

Thanks alot

-

@deckingman

Thanks

-

@mrehorstdmd

Despite these many problems, I was convinced to change the architecture of the device to the Hypercube model.

The point is, if I use anti backlash for Z lead screws , will we be sure that the device will not fall after the power cut? This issue of continuing to print after a power cut is very important to me.

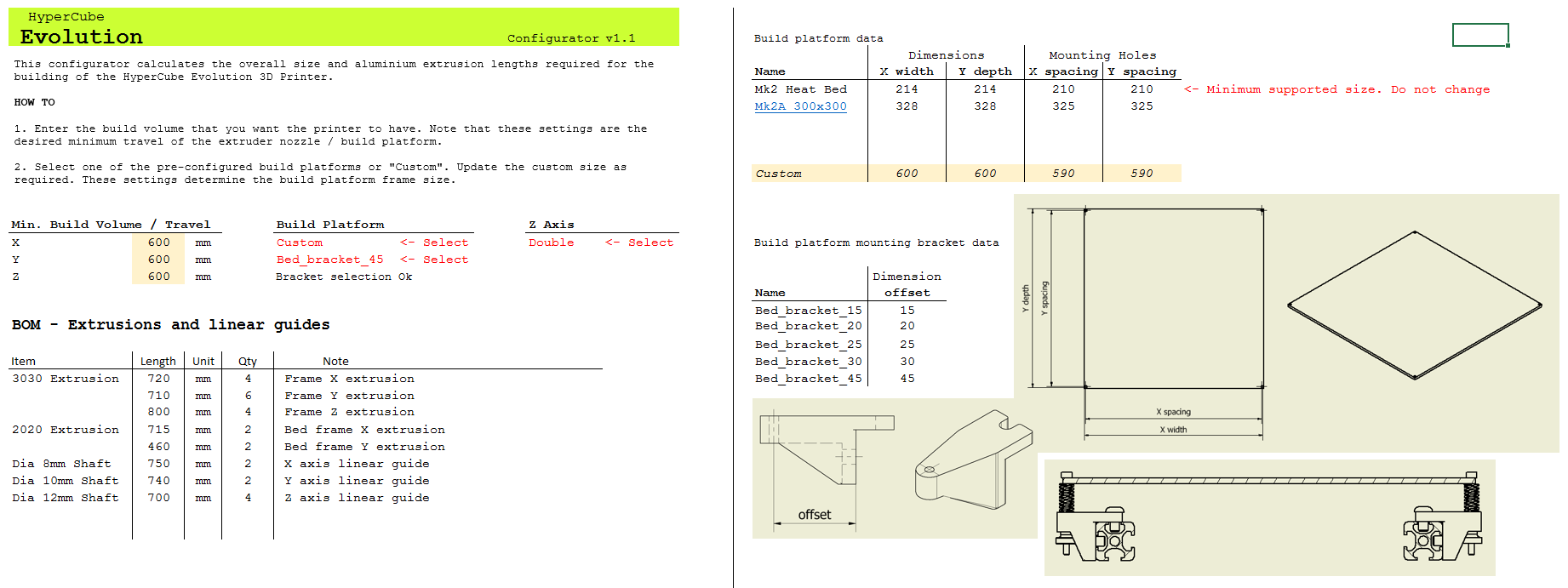

i see some 3030cm hypercube on "thingiverse" that the manufacturer had used 2 nema 17 to move bed in the Z direction. if i change the bed to 5050cm still can use 2 nema 17 to lift the z axis?This is the 30*30cm printer that caught my attention. Do you think I can convert this device to 50x50cm without changing Nima 17 motors, power, board, etc.

https://www.thingiverse.com/thing:2254103And this is the first time I see the printer datasheet.

In the table on the right side of the picture below, where it says 60x60, does it mean that it is easy to make this device with these specifications up to 60x60 dimensions without changing the parts?

Or for 60x60, electronic or mechanical parts must be changedand this is the datasheet of it:

And another question that I did not find the answer to is this. How should we know which engine to choose for the bad size we want?

Sometimes it is light and sometimes it is heavy.

Do you know the mathematical calculation of this case, how to find out which engine is suitable for our designed printer?Thanks alot

-

@mahmoudz Anti backlash nuts have nothing to do with whether the bed will drop on power loss. As I said in your other thread, gravity will ensure that the same flanks of the thread are always in contact, regardless off the direction of rotation so your Z axis will not suffer from backlash (assuming you use lead screws without and additional gearing. Also, as I've explained before, auto-rotation on power loss can happen if the lead of the screws is too big, giving a steep helix angle. You've already said that you intend to use 1mm lead screws (although the optimum is 2mm as I explained in the video link I sent you), so the bed will not drop on power loss.

As for sizing motors and the necessary calculations, I've already sent you links to the appropriate part of the documentation and I've even uploaded the spreadsheet that you'll need to my google drive, for which I gave you gave access link.

-

@mahmoudz There is a lead screw torque/force calculator here: https://www.daycounter.com/Calculators/Lead-Screw-Force-Torque-Calculator.phtml

Anti backlash nuts on the Z axis screws might keep the bed from dropping when power is cut, but it really hard to predict. It will depend on the mass of the bed, the pitch of the screws, the number of screws, and the friction of the anti backlash nuts. You also need to account for the mass of a large print on the bed, since you're building a big printer.

It looks like the plan you linked is based on 20 and 30 mm t-slot. That seems a little small for size the printer you want to build. Everything flexes. Small cross section things flex more than large cross section things. Again, it is hard to predict, so better to overbuild than underbuild.

The large bed plate will need a large heater. This calculator will help you calculate the power required to get the bed up to the desired print temperature in a reasonable amount of time: https://jscalc.io/calc/uS8JYjYISgIvzJ1x

I can't recommend the Arduino/RAMPS controller for any printer. Any board that uses tiny motor driver modules is going to be unreliable, as many of us found out years ago. Those motor driver modules can't dissipate enough heat, among their other problems.

No one can design this machine for you. You're going to have to invest some time and money in trying things until you find what works for you. Be prepared to make mistakes and changes as you go along. You'd really be better off starting with a small printer, that will teach you about the problems involved. It might save you a lot of money in the long run.

-

I have built a 60cm x 30cm printer about 8 yrs ago and have gone through all the trials and errors in order for it to be successful.

I started with a large cast aluminum build plate.(cast aluminum is known for dimensional stability and is used in precision fixturing.) While heating this plate it would deform and i had a huge problem keeping it level. The next phase was to use borosilicate glass. This solved the problem of deformation during heating and the plate stayed level. I use 2 lead screws for the Z axis and i do a bed level before every print. Keep the x y as light as possible as this is where the effects of weight will slow down the printing. I use a direct drive extruder and my print speed is restricted to around 60mm second. Travel speed is around 90mm sec. Although it is not a speed demon it works for me. I have explored the use of closed loop steppers and have found out that i can increase the speed slightly but in the long run it is not work the complexity at this time. I have performed prints that have duration of mor than 4 days printing time without issues. -

@percar said in Are these parts suitable for this 3D printer design?:

.............Keep the x y as light as possible as this is where the effects of weight will slow down the printing. I use a direct drive extruder and my print speed is restricted to around 60mm second. Travel speed is around 90mm sec.....................

If you are only printing at 60mm sec with 90mm/sec, why do you think that keeping X and Y as light as possible will affect the attainable speed?

I know the theory behind it that force = mass x acceleration so the lower the mass, the higher the acceleration that can be achieved for a given force (motor torque). But with FDM printing, the speed is limited by how fast the filament can be melted and extruded - the moving mass is not the limiting factor in this case. My own printer is a case in point. My 6 input hot end is heavy so it needs two parallel X rails which adds even more weight. The moving mass in the Y direction is about 2Kgs, yet I have demonstrated printing at 300mm/sec using all 6 inputs to achieve extremely high melt rates and with 1000mm/sec^2 acceleration. My default travel speed is always 350mm/sec - that's with 2Kgs of moving mass. So the concept that reducing mass will allow one to achieve higher print speed is a common misconception (i.e. why reduce mass if the mass itself is already below what would be a limiting factor?).

-

@deckingman

Hi sir. thank you. Yes, I downloaded it. Thank you very much again for your advice. -

@mrehorstdmd

Hello. Thank you very much for the tips and links you sent me. Yes, you are right that it is better to start with smaller sizes and after I have mastered it, proceed to make bigger printers. -

@percar

Hello. Thank you very much for the tips -

@deckingman

Hi sir. thank you.

I think I have to read all the messages again. Since English is not my native language, I am translating my questions and answers with the help of Google. And because in some places Google does not do this translation well, I may not understand some sentences well. -

@deckingman

hello. sir i have a few more questions.

if we use BLTouch and connect it to Zmin, There is no need to use mechanical endstops for the zmin axix?

And usually 3 end-stops ( 2 mechanical for x and y and one bltouch for z min) are enough for xycore pritners?I saw a video on YouTube saying that "Power less Recovery feature" in Marlin program may not work well for xycore printers. Thanks to your advice, I realized that if I use a 2 mm lead screw, the bed will not fall. The point is that if the bed does not fall, it is easy to use the power less recovery function in the Marlin program without any problem?

thanks.

-

@mahmoudz Yes to all of that.

-

@deckingman

Thanks alot sir.

You have taught me many things during this time.

Thank you very much.. -

@deckingman

Hi sir. I saw on the internet that some people use a system called V-slot wheels instead of using rails and wagons in 3D printers.

Is it worth using this system in the axes of the 3D printer, or will the wheels break down and wear out very quickly? Can you please guide me regarding the friction and life of these wheels and if these wheels are good, which model should I get? (because I realized that these wheels have different materials)

Thanks alot

-

Anybody using successfully resume after power cut?

Never tried it and am not sure how that work, considering the model cooling/heating cycle, and the lack of rehoming.

I wonder if a UPS would be a more effective solution, to avoid the power cut in the first place, even if just to the steppers if not to the heaters.

-

@mahmoudz said in Are these parts suitable for this 3D printer design?:

@deckingman

Hi sir. I saw on the internet that some people use a system called V-slot wheels instead of using rails and wagons in 3D printers.

Is it worth using this system in the axes of the 3D printer, or will the wheels break down and wear out very quickly? Can you please guide me regarding the friction and life of these wheels and if these wheels are good, which model should I get? (because I realized that these wheels have different materials)

Thanks alot

I built my printer entirely from Open Builds V-slot rails and wheels about 6years ago. Since then, it has run for thousands of hours without any problems related to the wheels and guides. I use a heavy mulit-input hot ends so have a moving mass in the Y direction of up to 3Kgs which is very high by most peoples standards, and my default travel speed is 350mm/sec which is also high by many peoples standards. Here is a video of how it looked 3 years ago with a 5 input Diamond hot end. Much has changed since then but the basic rails and wheels remain the same. https://www.youtube.com/watch?v=IG3AGKDzdH4

There are many more videos on my YouTube channel and writes ups in my blog - both of which are linked to in my signature below.

As you'll see from the video, I made many of my own aluminium parts for things like motor mounts but you can buy kits from the likes of RatRig and others - e.g. https://ratrig.com/3d-printing-cnc/3d-printer-kits/all-3d-printer-kits/v-core3configurable.html

My advice would be to use Open Builds solid or Delrin Wheels - not the Mini or Extreme versions. https://openbuildspartstore.com/wheels/

Pay particular attention to how you assemble them - use the Open Builds guides. e.g. https://www.youtube.com/watch?v=pMtHy7sDNG4. Most problems that people have had is because they haven't assembled the wheels correctly. The most common mistake is setting the eccentric spacer too tight. The next most common problem is forgetting to fit the precision spacer between the two bearings or over-tightening the lock nut. Any of these mistakes will prevent the wheel from rotating freely causing excessive wear.