Pattern Pressure Advance Calibration

-

@CCS86 It's still there! Tick "expert mode" up top

I will reduce glyph speed to first layer speed and see how they print for me -

@Ellis said in Pattern Pressure Advance Calibration:

@CCS86 It's still there! Tick "expert mode" up top

I will reduce glyph speed to first layer speed and see how they print for meAhh, missed that! Didn't notice it added settings to the other categories. Thanks.

Interestingly, testing at 70mm/s I see the sweet spot around 0.037

But at 120mm/s, the best value actually drops to around 0.028

-

@CCS86 PA seems to change at different speeds, same story with Klipper - unfortunately nothing can ever be simple, hah.

That's why I usually recommend to tune at your perim speeds, as that's where you will see it most

-

Ok, added firmware retracts and slowed the numbering down to first layer speed. They are looking cleaner for me now without having to bump flow

-

@Ellis

Ran it a couple times after those changes and it works sweet👌EDIT:

Based on the results it looks like 0.08-0.09 is where i should be, isn't that on the higher side for a direct drive setup(Voron Stealthburner loaded with a Revo Micro and a LGX Lite) ?🤔 -

@Exerqtor that does seem very high. With my LGX lite and Revo on a v0.1 I'm looking around 0.05

-

@Exerqtor PETG by chance? If so I've found it to need around double that of ABS/PLA. Abnormally high also can point to a sneaky partial clogs, even though it's still printing

-

@Ellis

ABS Pluss (Fiberlogy) actually @255c i haven't done a coldpull in a while so i could try that and run a new test ofc.

@255c i haven't done a coldpull in a while so i could try that and run a new test ofc. -

@jay_s_uk I made a few runs, tweaking some of the printing parameters and settled at 50mm/sec, 1.2 mm line width, accel 1000, PETG, 130C nozzle, 70C bed, 0.5 layer thickness, retraction, and z hop.

I shot some pictures of the result with PA stepped from 0.05 to 0.15 by 0.005 steps.

I don't really see much in the way of blobbing at the corners at the low value settings, but there are definite gaps that get bigger as PA increases.

After the first two steps, I don't see much change at the ends of the lines throughout the rest of the range. -

@mrehorstdmd The blobbing gets worse at higher speeds or lower accels, 50mm/s may just be a bit harder to read - though I imagine flow rate is a limitation here

This was with a 1mm nozzle? I'm also curious if the numbering printed okay, if you had that enabled. The preview freaks out a bit at such line widths since it renders the extrusions as cylinders instead of flattened ones.

My best real world results have been to pick the higher value a little before gapping, inversely to the usual recommendation of erring lower.

Looking at your results, it's certainly subtle. I'd hazard to guess around 0.055-0.06.

-

@Ellis Yes, 1mm nozzle. I didn't print the numbering- previous attempts resulted in illegible blobs- now that PA is "tuned" I need to check retraction- that may be why the text came out so poorly. I have struggled to get retraction tuned well with the 1 mm nozzle- you tune it up using test "posts" and get it working, but then you run a print and it doesn't look right, and after messing around, realize that the tuning worked because of the spacing of the test posts, and when the spacing changes, retraction gets ugly again.

A few years back someone wrote an add-on for Cura (IRIC) that varied retraction based on travel distance. I never got it working well, but maybe it needed PA, too. I'll be tweaking retraction later today.

-

@mrehorstdmd Currently the numbers are a static size, so the illegible blobs doesn't surprise me. I would need to figure out how to make them scale, I think.

Maybe I will disable numbering for >0.8mm nozzles for now.

Was hoping it would surprise me, but I'm not surprised

The retraction is an interesting idea. You could theoretically do that in a macro - in Klipper, at least, but I believe RRF3 macros aren't too far removed -

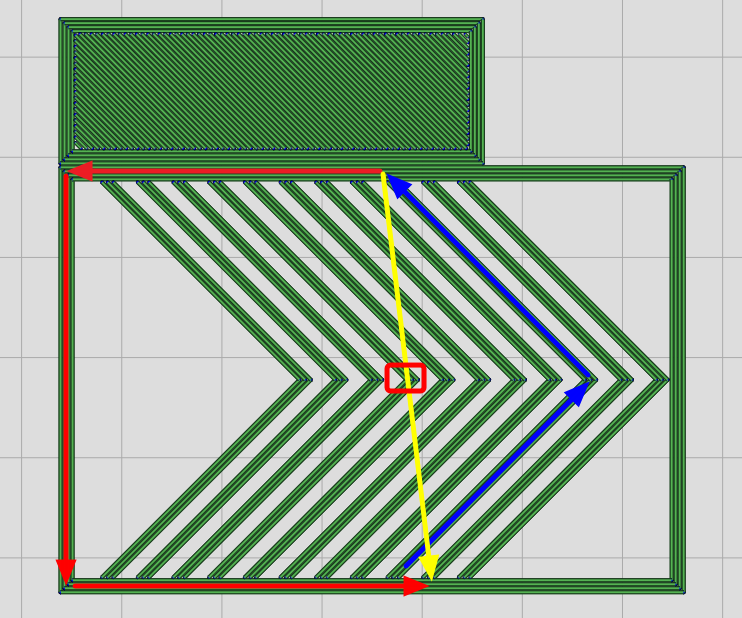

One though I had is on the travel moves between test lines:

To avoid test line damage from a travel move across the lines, and potential stringing deposition when using Z-hop, the travel could be re-routed like this:

I am looking at my test prints under a microscope and can see the nozzle strike marks and stringy depositions.

-

@CCS86 Interesting idea, but I don't think it's necessary, the part goes straight into the trash afterwards, a bit of stringing doesn't matter as long as its prints and is readable

-

@Ellis said in Pattern Pressure Advance Calibration:

@CCS86 Interesting idea, but I don't think it's necessary, the part goes straight into the trash afterwards, a bit of stringing doesn't matter as long as its prints and is readable

I'd argue that the stringing makes the print less readable, and without Z hop the nozzle strikes even more so.

-

@CCS86 nozzle strikes yes, stringing no

-

It's probably just me being dense, but what's the "correct" speed to use when your slicer is setup to have dramatically different internal(100mms) and external(40mms) perimeter speeds?

-

@Exerqtor Generally I try external speed first, and if it's not fast enough to show differences, I will fall back to internal speed.

-

Slightly off topic, I tried some retraction tuning using the "standard" two-towers type structure. The problem with all of them that I have seen is the towers are too small (typically 5 mm dia) and the plastic blobs a few layers into the print. Maybe my cooling is inadequate, but I think a larger tower size (maybe 20mm dia) that takes a little longer to print and allows a little more cooling to occur is probably a good idea, at least for a large nozzle. More experiments to follow.

-

@Ellis Would you be open to me using your script on my website to replace the current one ? www.advanced3dprinting.com is my site . Or i would love to have you post a blog article and you could put a tip link in it since i do get about 700-900 unique visitors a day so it should get you something in return .