CAN bus and Toolboard 1LC Connection Issues

-

@RogerPodacter more info, it doesnt seem to be the wiring, but something between the 2 toolboards. if i directly connect each board to the mainboard, each works normally. but only when i wire the toolboards in CAN series is when only 1 works but not the other. i'm very confused.

-

@RogerPodacter A couple of possibilities...

- Does the power supply you are using have the capacity for two boards with active heaters?

- Perhaps the wiring setup you are using (https://forum.duet3d.com/topic/30919/duet-3-mini-5-with-multiple-toolboards-1lc/3?_=1671973616337) is causing some sort of problem.

-

@gloomyandy I considered my power supply which is a Meanwell 200 Watt 24V. but i dont suspect it is the cause, but i dont know how to determine that. the PSU is still working normally.

if i starved the system of power, would that fry a board component? visually looking at the boards they are all fine.

i suspect its related to the termination resistor, and which connector i am using. is there a different between CANBUS 1 and 3, or 2 and 4, as long as i pair L to L and H to H?

-

@RogerPodacter to add more details, if i simplify everything and simply take my new toolboard connected to the mainboard, i get no connection if i use the 3 and 4 CAN, but connecting to 1 and 2 gives a solid connection.

on the ending toolboard, i have the pads soldered which incorporates the 120 ohm resistor. so i am using 3 and 4 connectors.

-

@RogerPodacter said in CAN bus and Toolboard 1LC Connection Issues:

if i directly connect each board to the mainboard, each works normally

Are you able to get the toolboard firmwares updated to match the mainboard when directly connected?

-

@Phaedrux yes i did upgrade so now both toolboards are on 3.4.2 firmware.

all i can think is i somehow damaged one of the boards. under the microscope i see no damage anywhere, specifically the CAN bus and controller chip. BUT, the original toolboard has some minor black charred on the metal power connector when i remove the power connector. its been in use for months so perhaps its from prolonged use.

so right now it looks like only one side of the CAN bus seems to work. both toolboards work if i plug directly into the mainboard, using CAN 3 and 4. but putting any of them in series using CAN 1 and 2, simply no communication.

my 200 watt Meanwell PSU is underpowered to run 2 toolboards pulling 5A each. so maybe that is the cause...

EDIT: i am using 60w heaters so my current draw would be 2.5A at 24V maximum per toolhead, so i doubt it could be related to power levels.

-

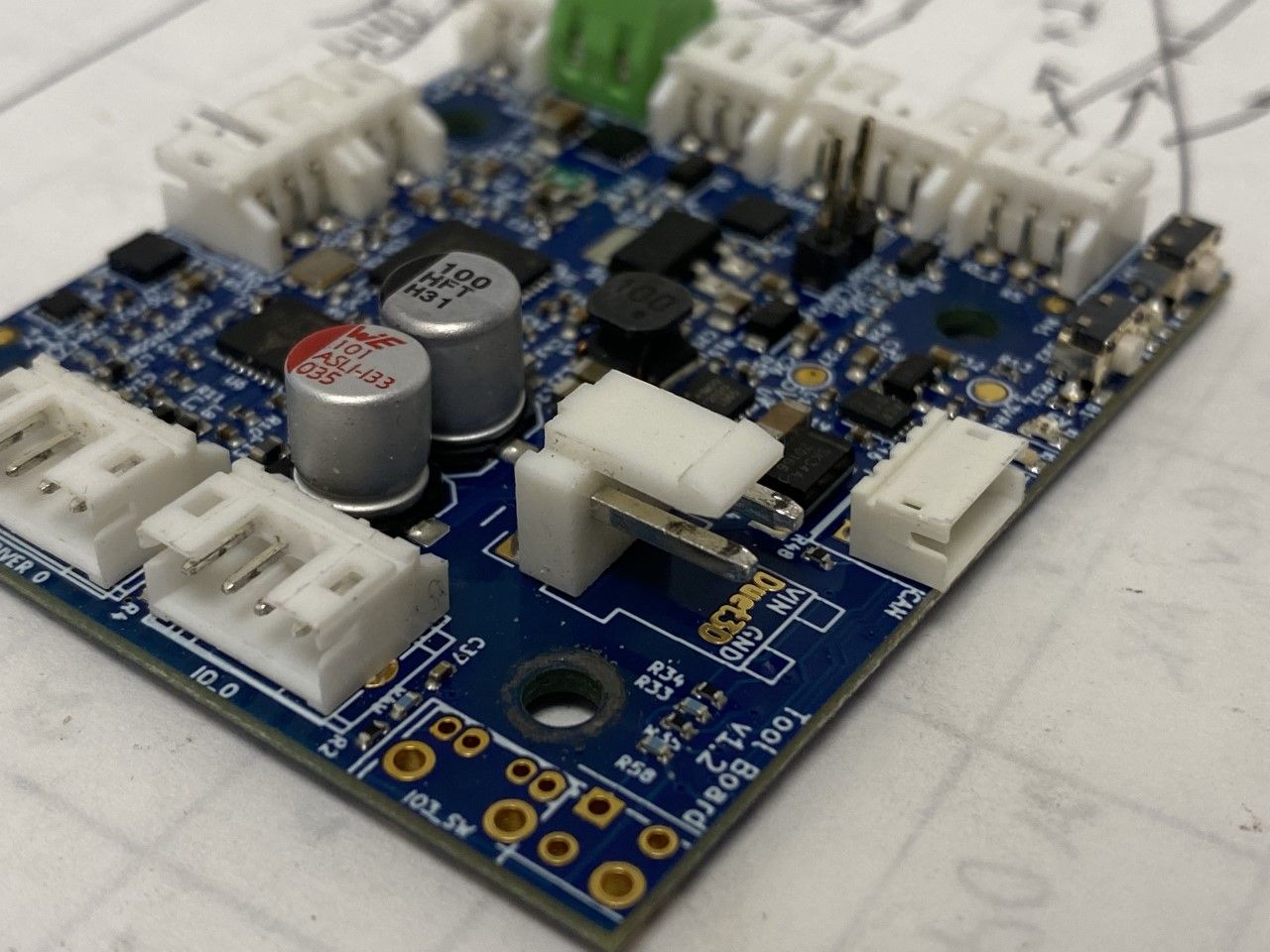

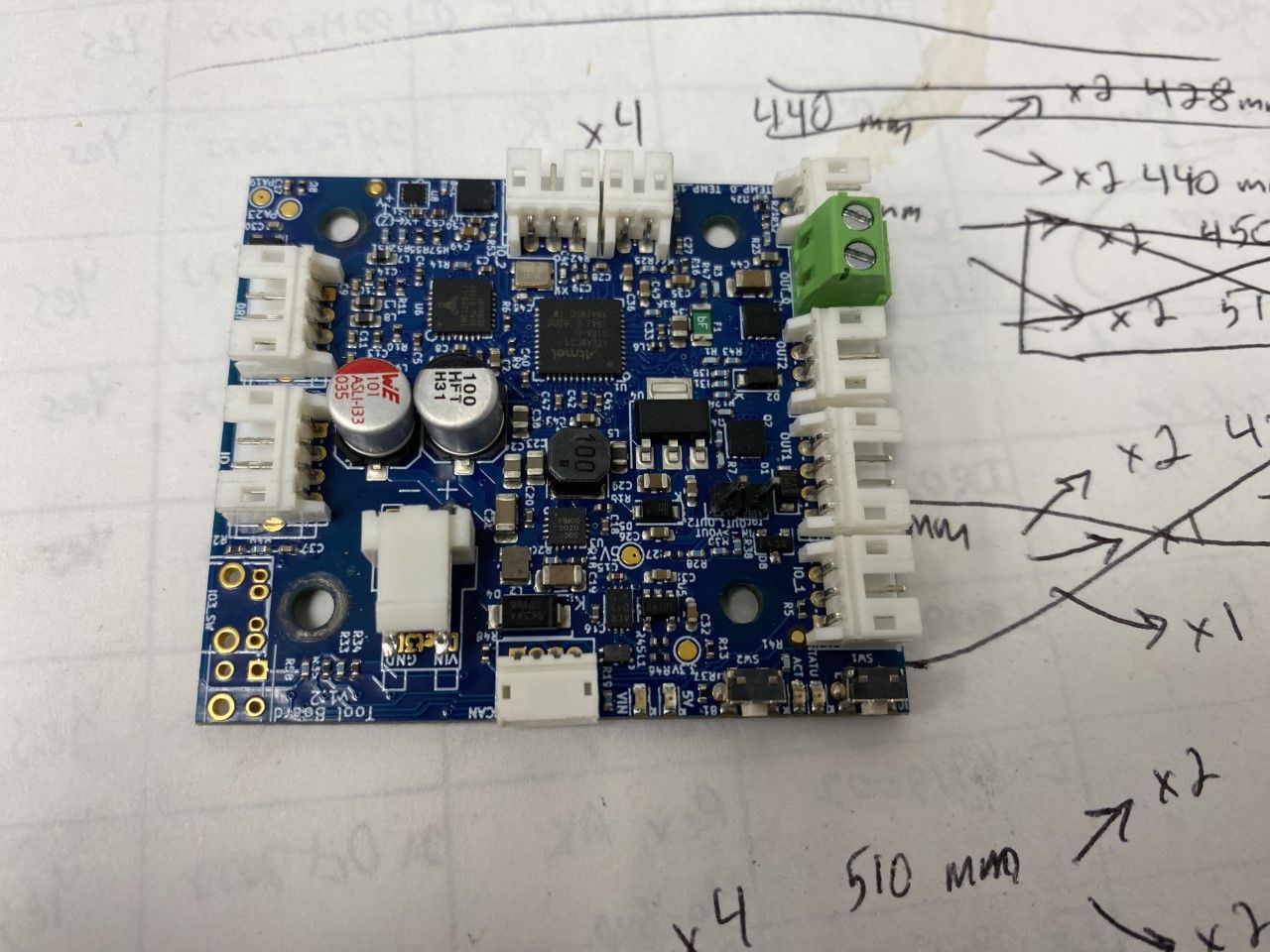

@RogerPodacter Does this look damaged/blackened power connection?

-

@RogerPodacter I am stumped. here is M122 from each toolboard.

Original 1LC

12/31/2022, 2:02:09 PM M122 B20 Diagnostics for board 20: Duet TOOL1LC rev 1.1 or later firmware version 3.4.2 (2022-09-13 15:06:56) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) All averaging filters OK Never used RAM 3044, free system stack 88 words Tasks: Move(notifyWait,0.0%,153) HEAT(notifyWait,0.1%,99) CanAsync(notifyWait,0.0%,65) CanRecv(notifyWait,0.0%,76) CanClock(notifyWait,0.0%,65) ACCEL(notifyWait,0.0%,61) TMC(notifyWait,3.0%,57) MAIN(running,92.0%,441) IDLE(ready,0.0%,26) AIN(delaying,4.9%,142), total 100.0% Last reset 00:04:25 ago, cause: power up Last software reset data not available Driver 0: pos 0, 80.0 steps/mm,standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 1499, writes 9, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -2/6, peak Rx sync delay 194, resyncs 0/0, no step interrupt scheduled VIN voltage: min 7.1, current 24.1, max 24.1 MCU temperature: min 22.5C, current 35.2C, max 35.3C Last sensors broadcast 0x00000000 found 0 18 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 2148, send timeouts 206, received 336, lost 0, free buffers 37, min 37, error reg 610000 Last cancelled message type 4519 dest 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer: LIS3DH, status: 00 I2C bus errors 0, naks 3, other errors 0New 1LC

12/31/2022, 2:00:31 PM M122 B21 Diagnostics for board 21: Duet TOOL1LC rev 1.1 or later firmware version 3.4.2 (2022-09-13 15:06:56) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) All averaging filters OK Never used RAM 2624, free system stack 88 words Tasks: Move(notifyWait,0.0%,153) HEAT(notifyWait,0.1%,113) CanAsync(notifyWait,0.0%,65) CanRecv(notifyWait,0.0%,76) CanClock(notifyWait,0.0%,65) ACCEL(notifyWait,0.0%,61) TMC(delaying,3.0%,57) MAIN(running,92.0%,351) IDLE(ready,0.0%,26) AIN(delaying,4.9%,148), total 100.0% Last reset 00:02:48 ago, cause: power up Last software reset data not available Driver 0: pos 0, 400.0 steps/mm,standstill, SG min 0, read errors 0, write errors 0, ifcnt 14, reads 18239, writes 14, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -2/10, peak Rx sync delay 186, resyncs 1/0, no step interrupt scheduled VIN voltage: min 7.1, current 24.3, max 24.3 MCU temperature: min 22.1C, current 27.3C, max 27.3C Last sensors broadcast 0x00000008 found 1 197 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 3200, send timeouts 22, received 854, lost 0, free buffers 37, min 37, error reg ff0000 Last cancelled message type 4519 dest 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer: LIS3DH, status: 00 I2C bus errors 0, naks 3, other errors 0 -

@RogerPodacter Apologies, please close this thread as resolved. the entire time the CAN connection was lose. the factory one ironically. once i recrimped it, everything works normally. it was just coincidental timing, the carriage motion must have loosened it up.

-

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved

-

@RogerPodacter I am glad you solved it. I suspect my toolchanger has a similar problem because the wiring to one of the tool boards does not pass the CAN bus through. For now I have used the jumpers on the tool distribution board to provide a bypass, but this isn't ideal.