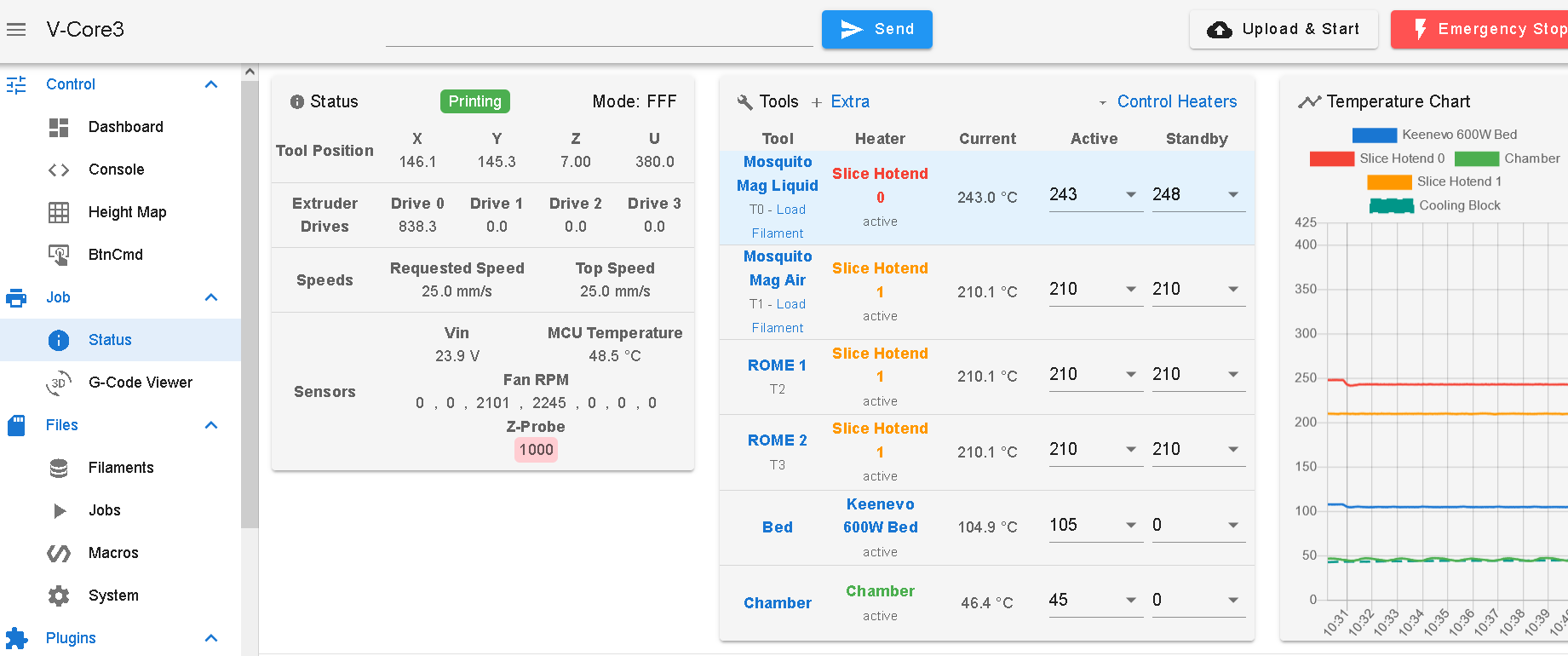

I have a strange issue. I run an IDEX printer, and on my 2nd print head i have a Y feeder to accept 2 filaments. I manage which filament is loaded with a simple 5V switch connected to IO0 on toolboard 21 (1LC).

This setup has been working for months. I took a 1 month break from printing and now when i go to use this print head the switch does not respond. When clicking the switch the toolboard reboots, so it seems the switch shorts the pin with each button press. Perhaps i changed something and dont remember, but to my knowledge everything should be in a working state.

Any advice how to troubleshoot this? also i have multiple spare switches to use and when i swap one in they all short the board, so unlikely to be faulty switch.

below are my settings:

config.g (line 205 is the switch in question)

config(1).g

Console Outputs

10/3/2023, 7:10:47 AM Warning: Board 21 does not have input handle 10c0

Error: bad model parameters

Accelerometer 20:0 type LIS3DH with orientation 14 samples at 1344Hz with 10-bit resolution

Warning: Board 21 does not have input handle 2000

Warning: the height map was loaded when the current Z=0 datum was not determined by probing. This may result in a height offset.

Warning: Macro file config-override.g not found

Error: in file macro line 232 column 20: meta command: variable 'daemonLoop' already exists

10/3/2023, 7:10:45 AM M98 P"config.g"

HTTP is enabled on port 80

FTP is disabled

TELNET is disabled

10/3/2023, 7:05:38 AM M122 B21

Diagnostics for board 21:

Duet TOOL1LC rev 1.1 or later firmware version 3.4.2 (2022-09-13 15:06:56)

Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1)

All averaging filters OK

Never used RAM 2864, free system stack 88 words

Tasks: Move(notifyWait,0.0%,153) HEAT(notifyWait,0.1%,115) CanAsync(notifyWait,0.0%,65) CanRecv(notifyWait,0.0%,76) CanClock(notifyWait,0.0%,65) ACCEL(notifyWait,0.0%,61) TMC(delaying,3.0%,57) MAIN(running,92.0%,441) IDLE(ready,0.0%,26) AIN(delaying,4.9%,142), total 100.0%

Last reset 00:03:04 ago, cause: power up

Last software reset data not available

Driver 0: pos 0, 80.0 steps/mm,standstill, SG min 0, read errors 0, write errors 0, ifcnt 9, reads 9545, writes 0, timeouts 0, DMA errors 0, CC errors 0, steps req 0 done 0

Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0

Peak sync jitter -3/6, peak Rx sync delay 189, resyncs 0/0, no step interrupt scheduled

VIN voltage: min 24.3, current 24.3, max 24.3

MCU temperature: min 34.8C, current 34.9C, max 36.0C

Last sensors broadcast 0x00000000 found 0 39 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 182, send timeouts 0, received 331, lost 0, free buffers 37, min 37, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0

Accelerometer: LIS3DH, status: 00

I2C bus errors 0, naks 0, other errors 0

10/3/2023, 7:05:32 AM M122 B20

Diagnostics for board 20:

Duet TOOL1LC rev 1.1 or later firmware version 3.4.2 (2022-09-13 15:06:56)

Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1)

All averaging filters OK

Never used RAM 2272, free system stack 31 words

Tasks: Move(notifyWait,15.9%,99) HEAT(notifyWait,80.7%,75) CanAsync(notifyWait,0.0%,59) CanRecv(notifyWait,8.5%,74) CanClock(notifyWait,3.3%,65) ACCEL(notifyWait,0.0%,61) TMC(delaying,521.5%,57) MAIN(running,343.3%,349) IDLE(ready,0.0%,26) AIN(delaying,277.9%,142), total 1251.2%

Last reset 47:59:53 ago, cause: software

Last software reset data not available

Driver 0: pos 7001169, 690.0 steps/mm,standstill, SG min 0, read errors 11, write errors 1, ifcnt 71, reads 14565, writes 25, timeouts 12, DMA errors 0, CC errors 0, failedOp 0x6a, steps req 13174689 done 13174689

Moves scheduled 300963, completed 300963, in progress 0, hiccups 0, step errors 0, maxPrep 905, maxOverdue 4, maxInc 1, mcErrs 0, gcmErrs 0

Peak sync jitter -5/14, peak Rx sync delay 228, resyncs 0/0, no step interrupt scheduled

VIN voltage: min 23.4, current 24.1, max 24.2

MCU temperature: min 30.5C, current 31.1C, max 54.2C

Last sensors broadcast 0x00000312 found 4 136 ticks ago, 0 ordering errs, loop time 1

CAN messages queued 3456488, send timeouts 0, received 2890902, lost 0, free buffers 37, min 35, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 1166, adv 35486/74643

Accelerometer: LIS3DH, status: 00

I2C bus errors 0, naks 3, other errors 0

10/3/2023, 7:05:02 AM M122 B1

Diagnostics for board 1:

Duet EXP3HC rev 1.02 or later firmware version 3.4.2 (2022-09-13 15:05:23)

Bootloader ID: SAME5x bootloader version 2.4 (2021-12-10)

All averaging filters OK

Never used RAM 158256, free system stack 178 words

Tasks: Move(notifyWait,0.1%,160) HEAT(notifyWait,4.9%,88) CanAsync(notifyWait,0.0%,69) CanRecv(notifyWait,2.8%,80) CanClock(notifyWait,1.4%,71) TMC(notifyWait,169.8%,99) MAIN(running,272.4%,407) IDLE(ready,0.0%,40) AIN(delaying,243.9%,263), total 695.3%

Last reset 47:59:20 ago, cause: software

Last software reset data not available

Driver 0: pos 0, 690.0 steps/mm,standstill, SG min 0, mspos 8, reads 7758, writes 17 timeouts 0, steps req 0 done 0

Driver 1: pos 0, 690.0 steps/mm,standstill, SG min 0, mspos 8, reads 7759, writes 17 timeouts 0, steps req 0 done 0

Driver 2: pos 0, 80.0 steps/mm,standstill, SG min 0, mspos 8, reads 7765, writes 12 timeouts 0, steps req 0 done 0

Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0

Peak sync jitter -10/13, peak Rx sync delay 183, resyncs 0/0, no step interrupt scheduled

VIN voltage: min 23.6, current 24.2, max 24.3

V12 voltage: min 12.3, current 12.3, max 12.3

MCU temperature: min 29.2C, current 30.3C, max 38.2C

Last sensors broadcast 0x00003000 found 2 62 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 2764197, send timeouts 0, received 2589022, lost 0, free buffers 37, min 37, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0

10/3/2023, 7:04:56 AM M122 B0

=== Diagnostics ===

RepRapFirmware for Duet 3 Mini 5+ version 3.4.2 (2022-09-13 15:14:33) running on Duet 3 Mini5plus WiFi (standalone mode)

Board ID: J6RFD-NR6KL-K65J0-409NN-LK02Z-7M5YU

Used output buffers: 1 of 40 (40 max)

=== RTOS ===

Static ram: 103684

Dynamic ram: 115484 of which 28 recycled

Never used RAM 18844, free system stack 98 words

Tasks: NETWORK(ready,286.2%,185) HEAT(notifyWait,11.4%,336) Move(notifyWait,28.1%,256) CanReceiv(notifyWait,18.0%,772) CanSender(notifyWait,0.8%,325) CanClock(delaying,1.4%,339) TMC(notifyWait,221.4%,72) MAIN(running,583.9%,417) IDLE(ready,588.7%,30) AIN(delaying,157.7%,263), total 1897.7%

Owned mutexes: HTTP(MAIN)

=== Platform ===

Last reset 47:59:14 ago, cause: software

Last software reset at 2023-10-01 07:05, reason: User, GCodes spinning, available RAM 19684, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00000000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x04

Aux0 errors 0,0,0

MCU revision 3, ADC conversions started 172754287, completed 172754287, timed out 0, errs 0

Step timer max interval 1488

MCU temperature: min 41.9, current 43.0, max 51.1

Supply voltage: min 23.2, current 24.0, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 99/2, heap memory allocated/used/recyclable 2048/228/196, gc cycles 224663

Events: 0 queued, 0 completed

Driver 0: standstill, SG min 0, read errors 0, write errors 1, ifcnt 85, reads 41730, writes 33, timeouts 0, DMA errors 0, CC errors 0

Driver 1: standstill, SG min 0, read errors 0, write errors 1, ifcnt 85, reads 41729, writes 33, timeouts 0, DMA errors 0, CC errors 0

Driver 2: standstill, SG min 0, read errors 0, write errors 1, ifcnt 85, reads 41729, writes 33, timeouts 0, DMA errors 0, CC errors 0

Driver 3: standstill, SG min 0, read errors 0, write errors 1, ifcnt 77, reads 41732, writes 29, timeouts 1, DMA errors 0, CC errors 0, failedOp 0x6c

Driver 4: standstill, SG min 0, read errors 0, write errors 1, ifcnt 95, reads 41727, writes 35, timeouts 1, DMA errors 0, CC errors 0, failedOp 0x01

Driver 5: standstill, SG min 0, read errors 0, write errors 1, ifcnt 97, reads 41727, writes 35, timeouts 0, DMA errors 0, CC errors 0

Driver 6: standstill, SG min 0, read errors 0, write errors 1, ifcnt 97, reads 41726, writes 35, timeouts 1, DMA errors 0, CC errors 0, failedOp 0x71

Date/time: 2023-10-03 07:04:56

Cache data hit count 4294967295

Slowest loop: 387.01ms; fastest: 0.07ms

=== Storage ===

Free file entries: 9

SD card 0 detected, interface speed: 22.5MBytes/sec

SD card longest read time 37.2ms, write time 33.2ms, max retries 0

=== Move ===

DMs created 83, segments created 34, maxWait 66015530ms, bed compensation in use: mesh, comp offset -0.019

=== MainDDARing ===

Scheduled moves 87832, completed 87832, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 17], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters 2 -1 -1 -1, ordering errs 0

Heater 0 is on, I-accum = 0.4

Heater 1 is on, I-accum = 0.0

Heater 2 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is ready with "M122 B0" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0 0, running macro

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== CAN ===

Messages queued 1856432, received 8632788, lost 0, boc 0

Longest wait 3ms for reply type 6053, peak Tx sync delay 390, free buffers 18 (min 10), ts 863771/863770/0

Tx timeouts 0,0,0,0,0,0

=== Network ===

Slowest loop: 293.56ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8

= WiFi =

Network state is active

WiFi module is providing access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 2.1beta3

WiFi MAC address ea:68:e7:e5:63:f4

WiFi Vcc 3.39, reset reason Power up

WiFi flash size 2097152, free heap 40160

WiFi IP address 192.168.1.10

Connected clients 1

Clock register 00002001

Socket states: 0 0 0 0 0 0 0 0

0:1 Z0:0:1:0 U0:0:0:1; Matrix mapping for Axis - X:Y:Z:U

0:1 Z0:0:1:0 U0:0:0:1; Matrix mapping for Axis - X:Y:Z:U