Hobbyservo controlled part cooling fan (compressor+valve)

-

I made servo+ball valve, but I can't get it to work. The wire colors on the servo are not the same as on its product page, so I'm only assuming that red is +, black is GND and white is PWM. I tried sending M280 P0 S80 with different values but nothing happens. I also could use some advice on how to use SSR to switch compressor on and off by sending G-code.

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Tue Dec 20 2022 09:34:36 GMT+0200 (Itä-Euroopan normaaliaika) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name M669 K1 ; select CoreXY mode ; Network M551 P"" ; set password M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes M569 P0.1 S0 ; physical drive 0.1 goes M569 P0.2 S0 ; Z1 motor (Left from user on printer) M569 P0.3 S1 ; Z2 motor (back motor) M569 P0.4 S0 ; Z3 motor (right from user on printer) M569 P0.5 S1 ; physical drive 0.5 goes forwards M584 X0.1 Y0.0 Z0.2:0.3:0.4 E0.5 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z640.00 E420.00 ; set steps per mm M566 X700.00 Y700.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z1000.00 E1800.00 ; set maximum speeds (mm/min) M201 X1800.00 Y1800.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1200:2600:1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X400 Y400 Z400 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io1.in" ; low end M574 Y1 S1 P"io2.in" ; low end M574 Z2 S1 P"io3.in+io4.in+io5.in" ; Z1, Z2, Z3 High end, Three ball scews M671 X-80.0:200.0:480.0 Y400.0:-40.0:400.0 ; Z leadscrews are at (-80,400), (200,-40) and (480,400) ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters ; BED M308 S0 P"temp1" Y"thermistor" T100000 B3974 ; configure sensor 0 as thermistor on pin temp1 M950 H0 C"out3" T0 ; create bed heater output on out3 and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ; HOTEND M308 S1 P"temp0" Y"pt1000" ;M308 S1 P"temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp0 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S320 ; set temperature limit for heater 1 to 320C ; Fans M950 F0 C"out9" Q500 ; create fan 0 on pin out9 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined M950 S1 C"out7" ; assign GPIO port 1 to out9 (Servo header), servo mode M280 P0 S80 ; Move servo with -

@Visionary said in Hobbyservo controlled part cooling fan (compressor+valve):

M950 S1 C"out7" ; assign GPIO port 1 to out9 (Servo header), servo mode

M280 P0 S80 ; Move servo withTry

M950 S1 C"out7" ; assign GPIO port 1 to out9 (Servo header), servo mode M280 P1 S80 ; Move servo with -

@Visionary

Just in case you didn't know:

The servo is pretty big. You can't use the 5V onboard regulator for this monster.

I use such a servo with a separate 5 cell NiMH battery. Just make sure the negative connection goes to servo and Duetboard. -

@OwenD said in Hobbyservo controlled part cooling fan (compressor+valve):

@Visionary said in Hobbyservo controlled part cooling fan (compressor+valve):

M950 S1 C"out7" ; assign GPIO port 1 to out9 (Servo header), servo mode

M280 P0 S80 ; Move servo withTry

M950 S1 C"out7" ; assign GPIO port 1 to out9 (Servo header), servo mode M280 P1 S80 ; Move servo withI tried this, but it didn't work

-

@o_lampe

I have seperate 5V PSU (DC-DC converter). Does it have to be connected to negative of Duet? If so can I use power in negative on 6HC board? -

@Visionary Yes - if you have multiple power supplies they need the 0V (negative) all at the same level, so must be connected together somewhere.

-

@achrn

I still can't get it to work. btw what I meant by 5V PSU it is actually DC-DC converter. -

@Visionary

DC-DC shouldn't work, if it's strong enough. Those digital servos are power hungry, they can consume 2A or more when blocked.

Does the Duet board supply 3.3V or 5V level on the servo PWM port? -

The converter can supply 5A and is rated at 25W. From what I read on documentation Duet ports probably cannot supply enough amps safely to this large servo.

-

@Visionary Servos can demand lots of current, so it's best to have a seperate supply, yes (though actually I use one without, but it does have a hefty capacitor across the supply). If it's DC-DC convertor they normally have the input and output -ve connected together internally, so that shouldn't be a problem.

My configuration is:

; Servo ; servo 1 on io7.out (note, needs to be 4, 5 or 7 as these are only PWM capable outputs) M950 S1 C"io7.out" ; create servo 1 M280 P1 S10 ; set to 10 degree position, which is blades closedI have the servo on one of the io connectors, and it seems happy getting 3.3V signals, but there's no guarantee any other servo will respnd to 3.3V.

I note that your config is repeatedly referring to 'out7' but the comment says out9 - where do you actually have the servo connected?

Have you checked the servo itself is happy on a 5V supply? You can use something like this: https://www.ebay.co.uk/itm/133527343417 (but I'm not endorsing that seller - that's just the first hit I got on ebay). This will confirm the servo is happy with the voltage and with 'ordinary' PWM signals (I'd specifically buy a cheap basic tester, so you know it's doing ordinary cheap basic signals to the servo).

-

@Visionary as @achrn says, for 5V PWM on a 6HC, you should connect the servo to the LASER/VFD pin, and configure for io9. See https://docs.duet3d.com/en/User_manual/Connecting_hardware/Motors_servos

Ian

-

I initially copied code for the servo from documentation and the comment is from there. The servo is connected to correct pin on the board. I tested another servo (ms-1.3-9) and it didn't work either. I'm assuming that with servo (MS-1.3-9) brown is negative, Red is positive and orange is PWM. Both servos should be able to handle 5V PWM.

I then switched to using 5V PWM pin "out9" on 6HC and that didnt work either.

The commands I'm sending to test the servo are:

- M280 P1 S0

- M280 P1 S35

-

@Visionary said in Hobbyservo controlled part cooling fan (compressor+valve):

I initially copied code for the servo from documentation and the comment is from there. The servo is connected to correct pin on the board. I tested another servo (ms-1.3-9) and it didn't work either. I'm assuming that with servo (MS-1.3-9) brown is negative, Red is positive and orange is PWM. Both servos should be able to handle 5V PWM.

Sorry, for avoidance of confusion, can you explicitly set out again what servo wires are connected where on the board and what is in the config.g.

Basically, when you say 'is connected to correct pin on the board' I don't know what that means in the context of someone saying it should be connected to the LASER/VFD pin, but the config.g referring to 'out7' - does that mean you've connected to out7 (which would be correct for the stated config, but wrong electrically, probably) or does it mean you've connected to the LASER pin (which would be correct electrically, but wrong for the stated config).

I also note that according to the posted config.g you've got fan 0 out out9. You can't have both a fan and a servo on that output.

-

-

@droftarts said in Hobbyservo controlled part cooling fan (compressor+valve):

@Visionary also, send

M98 P”config.g”And see if reports any errors.

Ian

This gives message : "Warning: Macro file ”config.g” not found"

I switched to attempting to get working the smaller (MS-1.3-9) servo.

I've connected it following way on 6HC:- Orange wire || Out9 (5V PWM)

- Red wire || +5V (external DC-DC converter)

- Brown wire || GND (external DC-DC converter, which is not directly connected atm to main 24V PSU GND)

I've also noticed that at start up the servo moves (after I removed fan assigments), but I still can't move it with G-code commands like M280 P5 S50. Instead the servo makes noise that indicates its trying to hold its position. The servo also makes random twiches and overheats the servo.

Note that I tried to switch number of the (P1) servo to different one (P5).

Current config:

; Configuration file for Duet 3 MB 6HC (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Tue Dec 20 2022 09:34:36 GMT+0200 (Itä-Euroopan normaaliaika) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"My Printer" ; set printer name M669 K1 ; select CoreXY mode ; Network M551 P"" ; set password. This is redacted. M552 P0.0.0.0 S1 ; enable network and acquire dynamic address via DHCP M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 S0 ; physical drive 0.0 goes M569 P0.1 S0 ; physical drive 0.1 goes M569 P0.2 S0 ; Z1 motor (Left from user on printer) M569 P0.3 S1 ; Z2 motor (back motor) M569 P0.4 S0 ; Z3 motor (right from user on printer) M569 P0.5 S1 ; physical drive 0.5 goes forwards M584 X0.1 Y0.0 Z0.2:0.3:0.4 E0.5 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z640.00 E420.00 ; set steps per mm M566 X700.00 Y700.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X9000.00 Y9000.00 Z600.00 E1800.00 ; set maximum speeds (mm/min) M201 X1800.00 Y1800.00 Z30.00 E250.00 ; set accelerations (mm/s^2) M906 X1000 Y1000 Z1200:2600:1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-25.8 Y-10 Z0 S1 ; set axis minima M208 X400 Y400 Z490 S0 ; set axis maxima ; Endstops M574 X1 S1 P"io1.in" ; low end M574 Y1 S1 P"io2.in" ; low end M574 Z2 S1 P"io3.in+io4.in+io5.in" ; Z1, Z2, Z3 High end, Three ball scews M671 X-80.0:200.0:480.0 Y400.0:-40.0:400.0 ; Z leadscrews are at (-80,400), (200,-40) and (480,400) ; Z-Probe M558 P0 H5 F120 T6000 ; disable Z probe but set dive height, probe speed and travel speed M557 X50:350 Y50:350 S300 ; define mesh grid ; Heaters ; BED M308 S0 P"temp1" Y"thermistor" T100000 B3974 ; configure sensor 0 as thermistor on pin temp1 M950 H0 C"out3" T0 ; create bed heater output on out3 and map it to sensor 0 M307 H0 B1 R0.25 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ; HOTEND M308 S1 P"temp0" Y"pt1000" ;M308 S1 P"temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin temp0 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S320 ; set temperature limit for heater 1 to 320C ; Fans ;M950 F0 C"out9" Q500 ; create fan 0 on pin out9 and set its frequency ;M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off ;M950 F1 C"out8" Q500 ; create fan 1 on pin out8 and set its frequency ;M106 P1 S1 H-1 ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ;Accelerometer M955 P0 I56 C"spi.cs3+spi.cs2" ; Servo for compressor fan valve M950 S5 C"out9" ; assign GPIO port 1 to out9 (Servo header), servo mode M280 P5 S30 ; Move servo with ; Compressor M950 P2 C"out2" Q0 ; Compressor ON/OFF SSR -

@Visionary try

M98 P”/sys/config.g”Regarding the M280 S parameter, see this note in the Gcode dictionary for M280: https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m280-set-servo-position

Almost all servos accept a pulse width range of at least 1us to 2us, which corresponds to an S parameter range of 44.2 to 141.2 degrees. So for many servos, values in the range 44.2 to 141.2 or alternatively 1000 to 2000 will cover the full operating range of the servo.

It could be your initial S30 is causing problems. Try higher values in the range suggested above.

Ian

-

@Visionary said in Hobbyservo controlled part cooling fan (compressor+valve):

I switched to attempting to get working the smaller (MS-1.3-9) servo.

I've connected it following way on 6HC:- Orange wire || Out9 (5V PWM)

- Red wire || +5V (external DC-DC converter)

- Brown wire || GND (external DC-DC converter, which is not directly connected atm to main 24V PSU GND)

I agree with that colour scheme and wiring layout. As previously, I would expect the DC-DC converter to have the 0V in and 0V out connected together internally (if you have a multimeter you could check there's no voltage across them, but I doubt this is the problem).

I've also noticed that at start up the servo moves (after I removed fan assigments), but I still can't move it with G-code commands like M280 P5 S50. Instead the servo makes noise that indicates its trying to hold its position. The servo also makes random twiches and overheats the servo.

That's slightly positive. Twitching servo sounds like it's at least trying to do something.

Current config:

; Servo for compressor fan valve M950 S5 C"out9" ; assign GPIO port 1 to out9 (Servo header), servo mode M280 P5 S30 ; Move servo withLooks OK to me.

I don't see anything wrong. At this point I'm grasping at straws, but:

- try some different S values in M280 (as @droftarts suggests)

- I see the fan is now commented out of the config file, but is anything still physically connected on OUT9? (I don't think it will matter actually, but worth a try disconnecting it if it is?)

- try connecting the orange wire to io7.out and changing the config line to

M950 S1 C"io7.out"andM280 P1 S<whatever>(this is just in case something is up with your out9 on the board, from config it doesn't look like you're using io7 yet)

-

@droftarts said in Hobbyservo controlled part cooling fan (compressor+valve):

@Visionary try

M98 P”/sys/config.g”This didn't work either, got the same error.

Almost all servos accept a pulse width range of at least 1us to 2us, which corresponds to an S parameter range of 44.2 to 141.2 degrees. So for many servos, values in the range 44.2 to 141.2 or alternatively 1000 to 2000 will cover the full operating range of the servo.

I didn't realize to check allowed servo angles. I thought they all started at 0 Degrees.

I checked the correct allowed pulse widths for both servos.

I changed to using microseconds in the command, but that didn't work and I got the same result. -

@achrn said in Hobbyservo controlled part cooling fan (compressor+valve):

I agree with that colour scheme and wiring layout. As previously, I would expect the DC-DC converter to have the 0V in and 0V out connected together internally (if you have a multimeter you could check there's no voltage across them, but I doubt this is the problem).

Tested the difference in voltage and it was 0V.

- try some different S values in M280 (as @droftarts suggests)

- I see the fan is now commented out of the config file, but is anything still physically connected on OUT9? (I don't think it will matter actually, but worth a try disconnecting it if it is?)

- try connecting the orange wire to io7.out and changing the config line to

M950 S1 C"io7.out"andM280 P1 S<whatever>(this is just in case something is up with your out9 on the board, from config it doesn't look like you're using io7 yet)

Switching S value didn't work (that were on the product page of the servo), but I might keep trying other values anyways. Nothing is connected to out9 (fan) pin. I changed to io7.out in config and rewired the servo and it behaves the same as before.

Btw how do you differentiate between fan pin out9 and 5V PWM pin out9 in config?

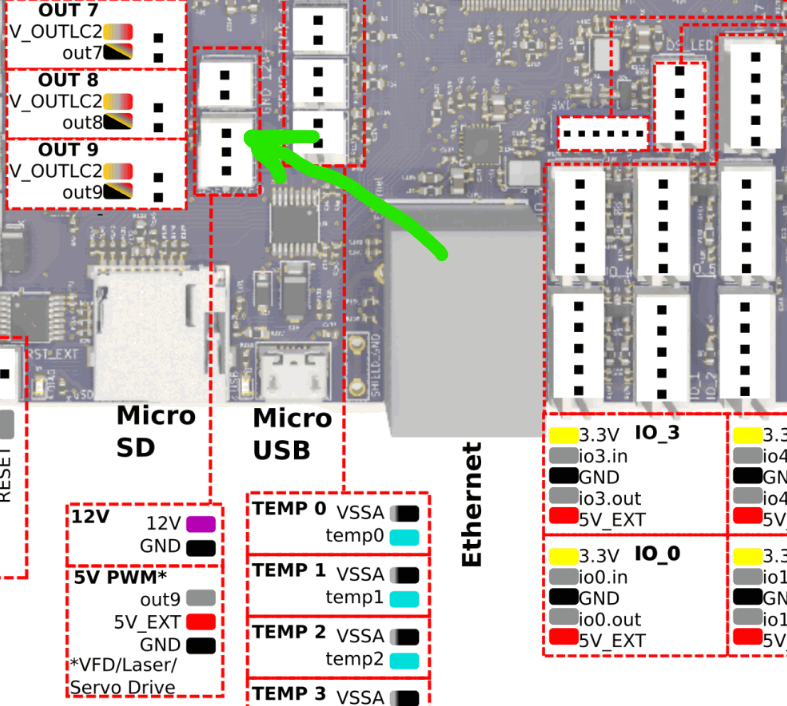

The green arrow points to the pin I've been using as out9.

-

@Visionary said in Hobbyservo controlled part cooling fan (compressor+valve):

Btw how do you differentiate between fan pin out9 and 5V PWM pin out9 in config?

You don't need to. Both pins are driven in parallel - the pin you've arrowed and the OUT9 fan (or whatever) connector next to it are both driven together - the arrowed pin is the control signal (at 5V) and the OUT9 connector next to it is the drain of a MOSFET that has that control signal applied to the gate.

That is, if you have a fan on OUT9 and control that as normal for a fan, the VFD/Laser/Servo pin will also be switching between 0V and 5V but you just leave the pin unconnected and that's not a problem. Alternatively, with the servo connected, the MOSFET is switching on and off in sync, but with nothing on that OUT9 connector that doesn't matter either.