setup needed for 6 extruders 5 feed 1 for direct drive

-

@run-it to confirm you have multiple tools, each configured with their own motor. + an additional motor that you want to run whenever any of the tool are running?

is the additional motor setup as another extruder, or as a movement axis?

If its another extruder motor then an idea that comes to mind would be to map it as a second extruder, with the appropriate mixing ratio. and then use the tool change macros to un map, and remap the extruder motors each time the tool changes.

-

all the extruders running with the tool I change to only using 5 and I have 6th open for a direct drive I would like it to run in tandem with each chosen tool

-

That sounds good would you and the filament gods have the code to do this? and what can I do to help out

-

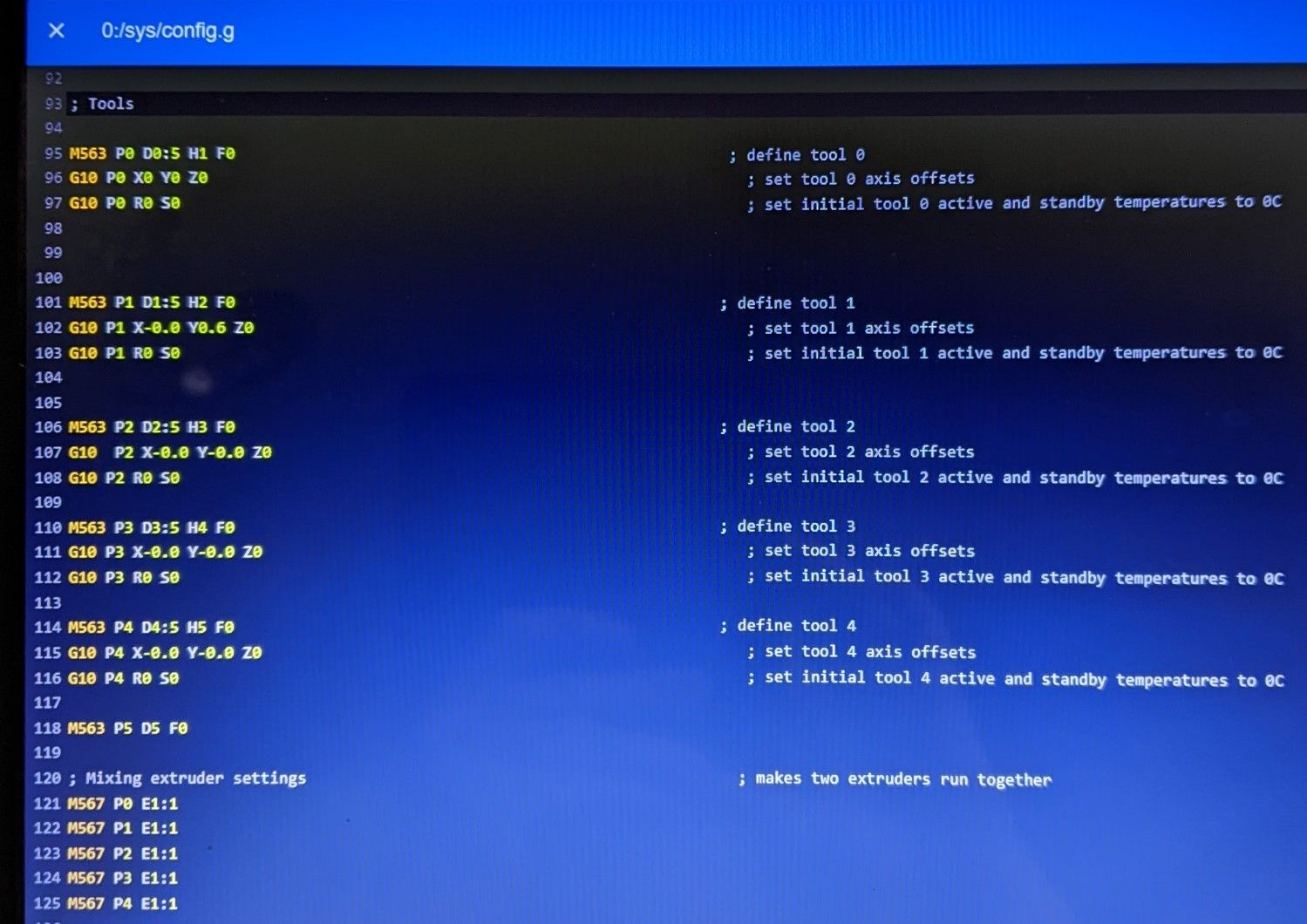

I was hoping that I could just put in my m563 D0:1 for T1 and D0:2 for T 2 and so on but did not work but did come up on wed interface next to extrude I tried setting up mix m567 p0 E1:1:0:0:0:0 for T0 m567 p1 E1:0:1:0:0:0 for T1 and so on. if I hit mix no joy if I highlight the two e buttons I get what I want but switching drops the highlighted buttons I know this is what your telling me right

-

@T3P3Tony I was hoping that I could just put in my m563 D0:1 for T1 and D0:2 for T 2 and so on but did not work but did come up on wed interface next to extrude I tried setting up mix m567 p0 E1:1:0:0:0:0 for T0 m567 p1 E1:0:1:0:0:0 for T1 and so on. if I hit mix no joy if I highlight the two e buttons I get what I want but switching drops the highlighted buttons I know this is what you're telling me right? so do I put the tool assignment code in the tool change? ie m563 D0:1 for T1. and I didn't know if I should text back here or on page reply

-

@run-it It would be less confusing if the drive which runs in tandem with the 5 extruders was designated as driver 5. Then your tool definitions for the 5 extruders (0 to 4) would look like this. T0 D0:5, T1 D1:5, T2 D2:5 etc. For drive 5 to to run in tandem, then you must define the mixing ratio for every tool as 1:1. You only need to set the mixing ratio for the drives that are assigned to tools, hence you only need 1:1 but you must use that for each and every tool.

-

@deckingman sounds great I will give this a shot. I will post the results. thank you for your time in helping me and others. catch ya later happy printing

-

@run-it Hello again I am very happy to say it's working thank you so much.

here's a pic of my changes for those who want to try this.

have a great day.

-

@T3P3Tony out of curiosity what would the macro look like for the filaments retract and tool change ? because him thinking doing like Op but with only 2 tool , going to a Y filaments guide to a single extruder.

-

@Dad003 Hi I think you could try looking up m701 load filament and m702 unload the filament and see if that will meet your needs.

I am going to try to set up the load to a switch or filament sensor. ie encoder. but I see I may have a problem with that because I use the web interface to load files not the sd card. and I found this in the g code directory (For all firmware versions, note that filament monitoring in RRF is only active when printing from SD card.) so this is kinda a drag if it is a true statement for today's firmware. -

@run-it said in setup needed for 6 extruders 5 feed 1 for direct drive:

I use the web interface to load files not the sd card. and I found this in the g code directory (For all firmware versions, note that filament monitoring in RRF is only active when printing from SD card.) so this is kinda a drag if it is a true statement for today's firmware.

The web interface uploads the file to the local SD card, so you have no issue.

-

@Phaedrux Awesome thank you