Parallel Scara based on Morgan.

-

@Phospherus nice, and this is probably not "off topic" so I have moved it as suggested by @o_lampe

-

Bit of an update firmware seems solid but unfortunately I thought 15mm diameter carbon fiber tube would be strong enough for the rotational forces and i was wrong. I have some twisting which causes a springiness on the inner shaft. Now going to 25mm for the inner shaft which is the diameter the outer used to be and 30mm for the outer.

I also purchased a set of https://www.amazon.com/gp/product/B0BQ728M9F/ref=ppx_yo_dt_b_asin_title_o01_s00?ie=UTF8&psc=1

These are 30:1 with 0.6 degree steppers. Supposed to have 2 Arcmin back lash which is 0.03 degree so should be plenty accurate. I thought about going true 5 bar with those mounted 45mm apart I would have the same print area as I do now. Anyone have any experience with these?

-

@Phospherus said in Parallel Scara based on Morgan.:

These are 30:1 with 0.6 degree steppers

The way I read it, it's a regular 1.8° motor and the 30:1 reduction results in 0.06°step angle

-

@o_lampe I see now thanks for pointing that out. I hope they are decent quality and good enough.

-

@Phospherus I'd wish you open it in a iFixit style and post some images to discuss the quality. Unfortunately - I completely understand it - you'll not want to do it because of the guarantee. But if it's damaged in the future, this would be valuable. They are out of stock and a bit too expensive to buy it just for testing.

-

@Phospherus It surprised me, that they took a short NEMA17 motor with low torque for it. I guess a full size motor would exceed the max. output torque of the harmonic drive.

-

First printing with the Scara looking good so far. No z endstop so set it with piece of paper and no heated bed as my PSU mount is printing so running off a 5 amp 24V power pack. Using a Bondtech BMG for bowden drive with a Phaetus BMO hotend. Link to youtube video below. This is my first time ever uploading to youtube so if it does not work I apologize and will fix it.

-

This post is deleted! -

This post is deleted! -

@o_lampe Video link should work now.

-

@Phospherus Looks good for a first print on a cold bed.

-

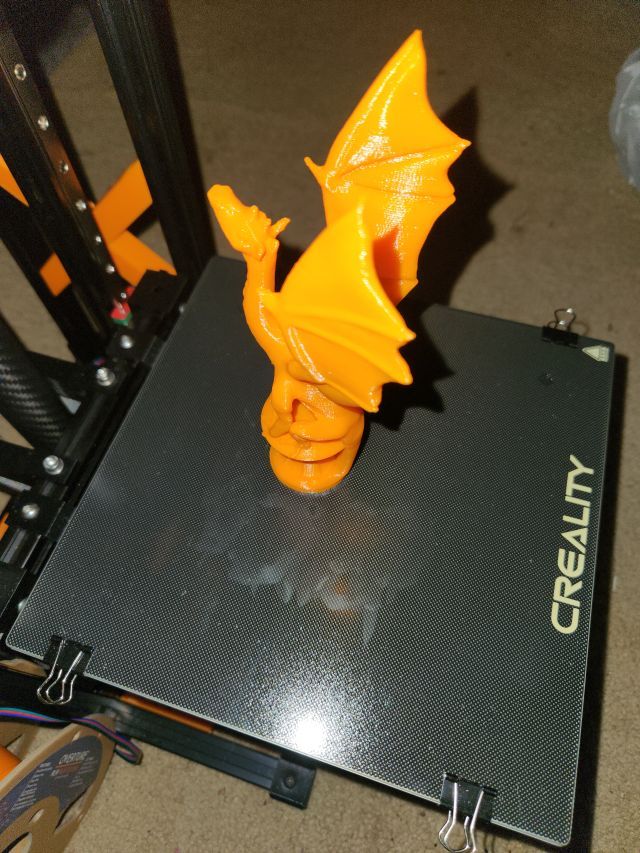

A couple pictures of the first print complete. I am amazed how good it came out without part cooling even.

-

Finally got a test set of arms printed and a mount for the Nema 17 harmonic drives. Here it is in action. https://youtube.com/shorts/bj47uQ08zV0?feature=share

-

@Phospherus It's always hard to qualify mechanics from a video. The first impression is good, no visible backlash or springiness.

Will be interesting to see it work, maybe with a feltpen for starters?

Would you use a direct drive extruder as toolhead or is it strictly Bowden-setup? How much does the head sag?