Scanning Z probe support in RRF 3.5

-

@dc42 Jeepers, these sausage fingers will struggle with that. Might have to ask a mate. It is hard to see where the upper connection point is from that photo

-

@dc42 do you have a similar connection guide for a Sammy board?

-

@CNCModeller when using our standard firmware build for the SammyC21, you would connect the SDA pin of the LDC1612 to PA22 and the SCL pin to PA23.

-

@samlogan87 said in Scanning Z probe support in RRF 3.5:

hard to see where the upper connection point i

I would say it is the left side of

R55R53. I would 3D a little housing and use two pogo pins to make the connection, so there would be no need to solder. I've ordered the Grove board and will make experiments also. -

@dc42 I have a 1.1 revision board which has the SWD Out plug where you have soldered onto. I am not going to do it now as I will wait for you to finish testing but where would I hook it up to?

-

@dc42 said in Scanning Z probe support in RRF 3.5:

@CNCModeller when using our standard firmware build for the SammyC21, you would connect the SDA pin of the LDC1612 to PA22 and the SCL pin to PA23.

Ok thanks, just ordered an LDC1612, should be here in a week or so. Something else to add to the list of upgrades for my printer.

I'm assuming that this would work for scanning copper clad PCBs or metallic stock on a CNC milling machine to determine a surface deviation map or the lowest height on a stock top surface for Z work offsets?

Cheers

Barry M -

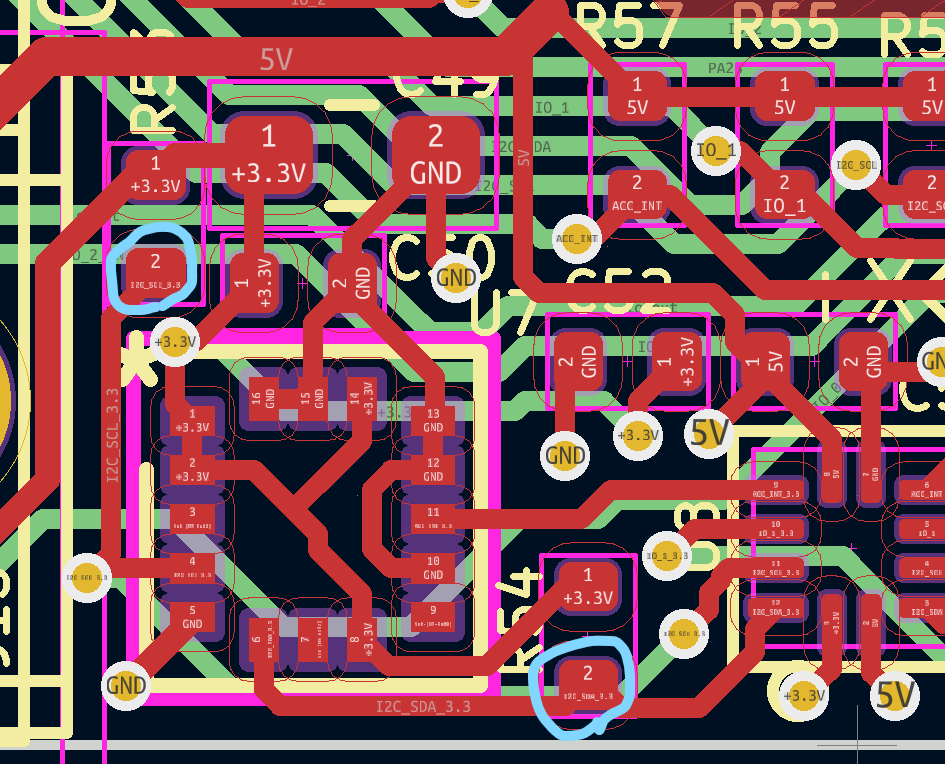

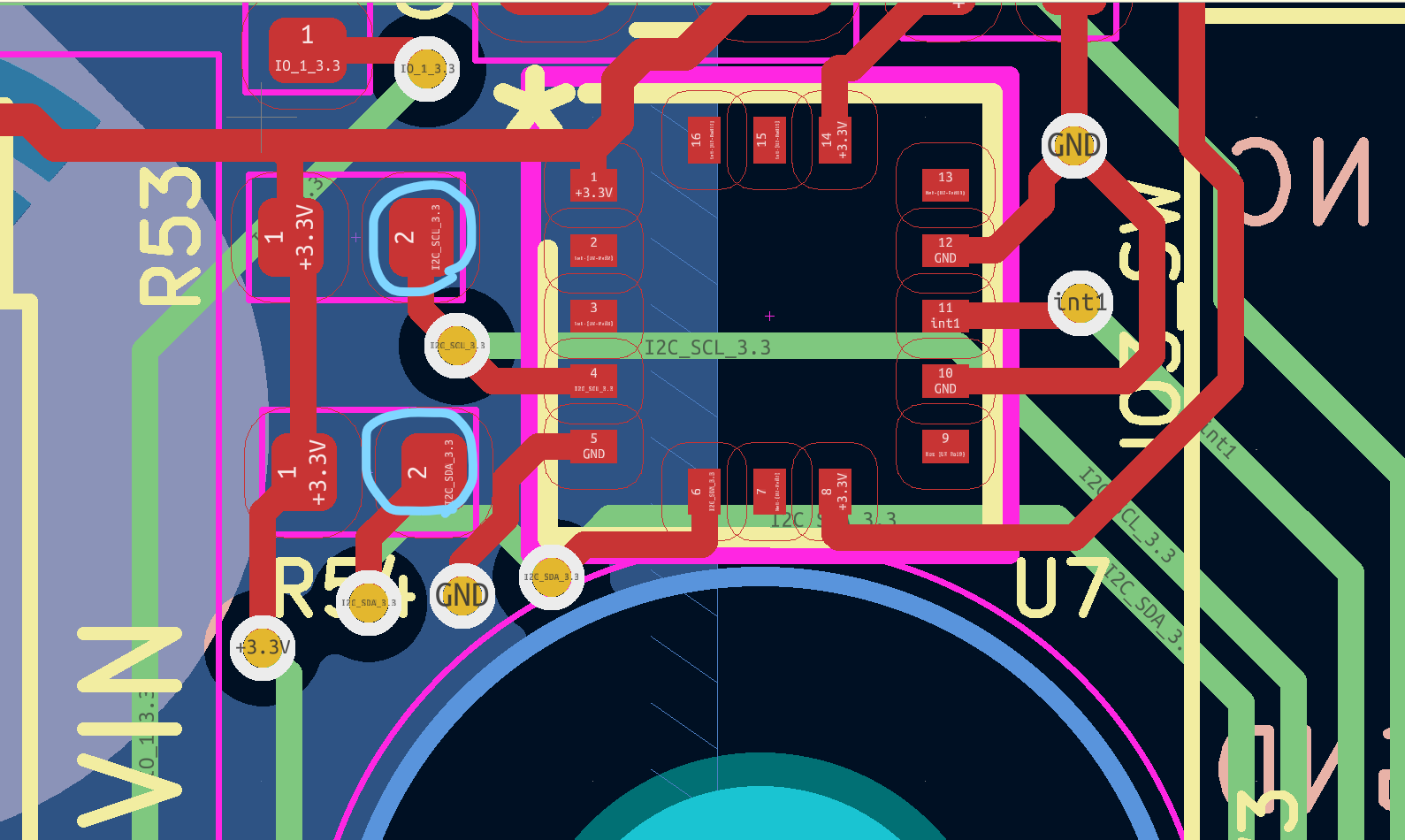

@samlogan87 here are the connections (circled in blue) for a revision 1.2 tool board, which is what I used. I'll take a look at where they would be made on a revision 1.1 board.

-

...and here are the corresponding connections on a version 1.1 tool board, again to resistors next to the accelerometer chip.

-

@dc42 could you share your M558 and M558.1 Gcode for the scanning probe?

-

@lparnell34 currently I use the standard tool changer Z probe microswitch for Z homing because it doesn't have the temperature sensitivity that inductive Z probes have. I have the scanning probe configured as an additional probe for use with G29. Here's an extract from config.g:

; Z probe M558 K0 P8 C"io3.in" H3 F1000:600 I0 T30000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds G31 P200 X0 Y0 Z0 ; Set Z probe trigger value, offset and trigger height ;M557 X-140:140 Y-80:80 S40 ; Define mesh grid ; Scanning Z probe M558 K1 P11 C"24.i2c.ldc1612" F25000 T30000 G31 K1 Z3 Y-17 M557 X-140:140 Y-90:80 S12 ; Define mesh gridI changed my mesh.g file to recognise the K1 parameter (i.e. use the second Z probe) and do the M558.1 calibration at the start to avoid possible temperature sensitivity issues:

T-1 M208 S0 Y100 if exists(param.K) & param.K=1 G1 X0 Y0 F30000 M558.1 K1 S2 G29 S0 K{exists(param.K) ? param.K : 0} G1 X0 Y0 F24000 M208 S0 Y49 G1 Y-150Then I send G29 K1 to do the scan. The M208 commands are included because on the tool changer, the Y axis limit depends on which tool is selected.

-

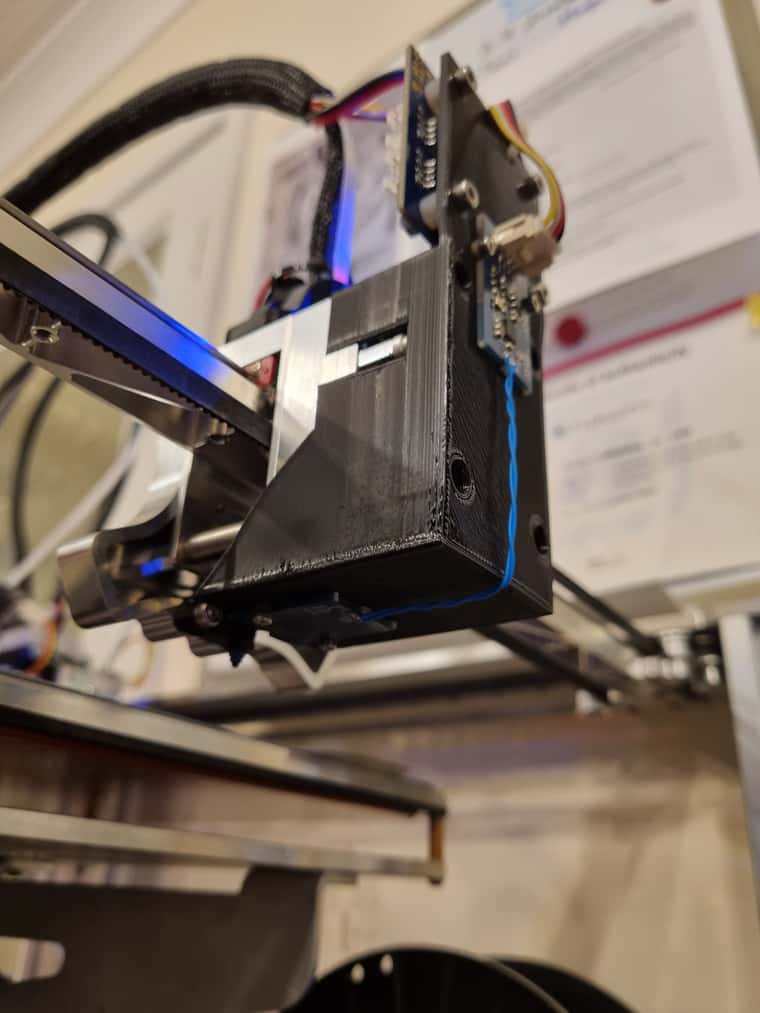

@dc42 thanks. I'm using the tool changer too. Do you just have the coil pcb mounted to the bottom of the toolhead cover?

-

@lparnell34 initially yes, however that gave a large Y offset between the coil and the Z probe switch; so I extended the cover towards the switch.

-

Here's a blog entry with more details about this scanning probe: https://www.duet3d.com/blog/scanning-z-probe-for-reprapfirmware-and-Duet.

-

This post is deleted! -

@dc42 do you guys think you will release a new version of the tool board where you put the i2c bus to a plug? Had another look tonight and there is no way I would be able to solder that

-

@JoergS5 I'm not sure why you deleted your post, however I had the same idea yesterday!

-

@dc42 I deleted it because I doubt whether the BL Touch is necessary in the future *). But to repeat my idea:

is it possible to bore a hole into the middle of the Grove coil and assemble it together with the BL Touch so the pin of the BL Touch goes through the coil hole. Then both have the same XY offset.

*) I thought about using a gauge block at a bed edge as Z0 reference.

Gauge blocks of class 0 have a precision of 0.1 micrometers. This could even be used with the LDC1612 measuring the angle of a rotated bed => 5 axis AC calibration, by measuring multiple points on the gauge block.The next idea was, if I don't use the BLTouch, I could use the bored coil to assemble it around the nozzle, so it has true X0Y0 position. The PCB needs to have enough distance to the heated nozzle...=> the aluminium heatblock will disturb measurement -

@JoergS5 my feeling at the moment is that because of the sensitivity of inductive sensors to temperature, and to allow a wider choice of bed surfaces including interchangeable beds, it's better to use a conventional touch probe or nozzle contact probe to establish Z=0 and perhaps to do bed tramming too. Then the scanning probe can be calibrated immediately before scanning, and its temperature sensitivity won't matter.

As you can see from the pictures at https://coolcomponents.co.uk/products/grove-2-channel-inductive-sensor-ldc1612 there is a blank area in the centre of the coil, so drilling a hole there would be possible.

We're designing a solution based on the LDC1612 at present and although we will be using a smaller sense coil than the Grove one, it's likely that we will include a hole in the centre and design a printable adapter to attach it to a BLTouch.

-

@dc42 said in Scanning Z probe support in RRF 3.5:

We're designing a solution based on the LDC1612 at present and although we will be using a smaller sense coil than the Grove one, it's likely that we will include a hole in the centre and design a printable adapter to attach it to a BLTouch.

@dc42 Wouldn't the inductive probe pick up the metal in the bltouch? I've assumed this was basically a small metal detector hence you'd need to keep any other metal outside of the coils sense area, or is that not the case?

-

@CNCModeller a small amount of metal in a fixed location relative to the coil shouldn't matter. In any case, the larger metal parts of the BLTouch are at the top so about 26mm away for where the coil would be.