Hollow shaft extruder

-

@o_lampe That's a nice idea. You would need a very stiff but small spring. A disc spring seems ideal.

The ring lever is also smart, I'm imagining an inverse "ramp" on the bottom of it which pushes the lever up and down, depending on the position of the lever. The bearings then press/ride against the smooth top of the lever.

This could be used to set a maximum tension as well. -

@nikscha The original VDE100 files are somewhere on thingiverse, including an (*) FreeCad parametric file.

I really suck with modifying any CAD when it's not my design. Do you volunteer to make a version of our idea?- The wavy washers might work, but they don't have much room to compress.

- The ring lever should hold a plain washer because the bearings will rotate on it.

- The spring force must be big enough to have working retraction without slip.

Couldn't find it there but on reprap-forum

Carrier#3.FCStd -

@o_lampe I never used freeCad but maybe I can make a copy of the design in Fusion. Will take a while though.

-

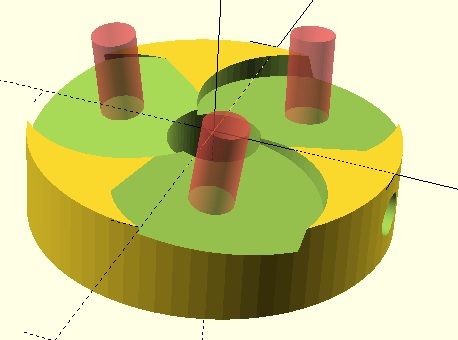

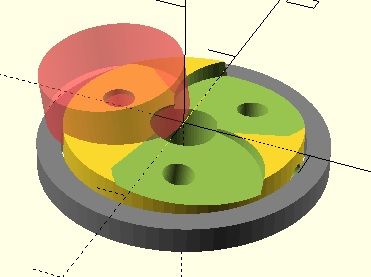

I translated the FreeCad data to OpenScad and added a variable "tilt"

Here's a 5° tilt

And the OpenScad file.

carrier_tilted.scadReduced carrier diameter and sort-off lever added, just for clarification

-

Hi all, I made the VDE-100 video that has been referenced a few times. I have been using the VDE-100 for a long time now and I love it. Several comments in response to the thread above:

@nikscha your maths was correct, tan(15) * 1.75 * pi is the theoretical thread pitch. In reality the knife edges tend to drag a bit through the filament resulting an a somewhat lower pitch.

Loading/unloading is pretty easy but, yes, it is done by instructing the extruder stepper to turn. I have my whole VDE-100 assembly attached via a quick release clip which also helps because occasionally a blob on the end of the filament went retract through the extruder. And the quick release is super cool for dealing with nozzle clogs, etc.

The extruder seems to just work on any filament (e.g. floppy TPU at one end of the scale and hard PLA at the other). But I think definitely avoid abrasive filament. I did print recently with GF filament and specifically swapped out my extruder for another that is not as nice as the VDE but has bondtech gears.

There have been suggestions about tensioning. I played around a lot with tensioning ideas, including using a similar idea to @nikscha's printed spokes. In the end, it just is not needed. The knife edges cut into the filament and that provides the tension. But it does mean you need fairly precise diameters @o_lampe. Since I found a way to cut those even with rudimentary tools, I am satisfied with that. Of course, you also need precise filament diameters, but that's pretty much a given these days.

Steppers getting hot: with the VDE-100 the stepper stays nice and cool because there is so little torque needed and so not much current is needed. I would think Ingenuity would have the same benefit.

Filament twisting in the VDE-100: this is surprisingly far less of a problem than you'd think. The melted plastic in the nozzle provides a fair back torque. And the shorter the part through the heatsink, the better this effect is. Once again, though, precision edge diameter is key. Cut too far into the filament and that creates more torque.

VDE files to play with: I published my files with FreeCAD model on printables.com.

-

@tombrazier With all due respect, but grinding an edge to a flanged bearing is not my favorite evening activity

I want to find an economic way to (mass-) produce the edge.

A self-adjusting design would reduce labour cost significantly. If it also adds a comfortable way to change filament, it's even better. -

@o_lampe said in Hollow shaft extruder:

With all due respect, but grinding an edge to a flanged bearing is not my favorite evening activity

Really? Why?

If you can work out a way of self adjusting I'd be very interested to see it. I didn't really follow the conversation above. I need a picture, I think.

-

@tombrazier thank you for the input! What kind of stepper are you using? And how much current? Do you happen to know how much weight it can lift? I did some rudimentary testing with the ingenuity and the most I could lift reliably was 4KG. Maybe more if I increase the current but as I said I don't really wanna do that because the filament gets too soft.

@tombrazier said in Hollow shaft extruder:

In the end, it just is not needed.

Really? It seems hard to believe but I'll take your word for it.

-

@nikscha @tombrazier

comparing your current/torque demands should start with comparing the stepper settings like microstepping and steps/mm.

The big LDX drivegear feeds almost 60mm filament/turn that requires a lot of torque.

From rq3's posts I've learned that the archimedes screw needs pretty high steps/mm setting. He even didn't use microstepping.

That resulted in a low max. extrusion speed (on Marlin @12V ).

His design went through several changes and Tom's carrier seems different again.

I'd be interested about the status quo regarding the latest numbers, Tom? -

@nikscha I have not tested but I think that my VDE extruder could not lift 4kg - or if it did it would experience some much widening of the grooves that the helical thread pitch on the filament would reduce to pretty much zero. However, 4kg equates to a nozzle pressure of something like 16MPa, which I think is probably a lot higher than ever would be needed for extrusion. With fluid dynamics, there is a point where flow stops being laminar and flow rate pretty much stops increasing with increased pressure. And with feeding filament through an extruder, there is a point where it is feeding too fast to fully melt, which also places a fairly abrupt upper limit on flow rate, regardless of pressure. Volcano and CHT type nozzles help but even they have their limits. I would be interested to know at what pressure the cut-off typically is, but naively I suspect it is below 16MPa. Stefan from CNC kitchen has done a lot of work exploring these limits but I can't remember whether he has put a load cell on his extruder to measure extrusion force at the limits of flow.

High flow rate is a bit of a weakness with the VDE because of the groove widening thing I mentioned above. I have vague ideas of experimenting with more flanged bearings and different edge shapes. But in reality it is only sub 20 minute speed benchies that challenge my VDE for flow rate so it's not my highest priority.

@o_lampe I don't think microstepping is relevant in the speed/torque calculations, but it is a factor when configuring the firmware. I have a 20° cant angle on my bearings and this results in a lower steps/mm than rq3 gets with his 15° cant angle. I am presently using use microstepping = 2 with my VDE and getting about 275 steps/mm (1.8° motor).

-

@tombrazier this is really valuable information, this means I could probably get away with a much lighter stepper. I'll do some testing with lower currents to see how little torque is actually required.

About the groove widening: why not stack a second ring with 3 more bearings on top? If you get the spacing right, the second ring won't even have to cut it's own groove, and the load is shared between the two.

-

@nikscha said in Hollow shaft extruder:

About the groove widening: why not stack a second ring with 3 more bearings on top? If you get the spacing right, the second ring won't even have to cut it's own groove, and the load is shared between the two.

Mainly because I have not needed to. I don't usually print fast enough for it to be a problem. But it is one idea I have thought about. Another that strikes me is that the edge I grind on the bearing has an included angle of 45° and rq3 uses 60°, but I suspect the ridges on a bondtech gear have more like 90°. I would be interested to know whether a wider included angle results in better grip. And another is to use symmetric edges as rq3 does, which I now have the means to grind whereas I did not previously.

-

@nikscha said in Hollow shaft extruder:

I'll do some testing with lower currents to see how little torque is actually required.

The trick will be to figure out at what speed your extruder's flow rate hits the wall. Then tune current so that the E stepper does not start losing steps before that point.

-

@tombrazier fair I could do that, but isn't that highly dependent on nozzle-dia, meltzone length, filament etc? I would get a number that works for me but maybe not for others, right?

Maybe I could test how much weight the LGX mini and the Orbiter (I have both) can lift and compare that to the Ingenuity. Then I have a rough estimate of what is "expected", and I can adjust the torque according

-

@tombrazier I'd think that a bigger included angle actually makes grip worse. My train of thought is that Bondtech can get away with 90° because more than 1 tooth is engaged in the filament, and they choose 90 degrees because it holds up better against abrasive filament.

It makes sense that you don't need the second ring with the speeds you're going at. But I'm surprised that you don't print faster with such a lightweight extruder. That seems to be the biggest advantage to me. What other reasons are there to use your extruder instead of the Orbiter for example? You mentioned something about ease of disassembly earlier I think?

-

@nikscha said in Hollow shaft extruder:

What other reasons are there to use your extruder instead of the Orbiter for example? You mentioned something about ease of disassembly earlier I think?How about the print artifacts attributed to dual drive gear extruders? I suspect the screw-type extruder doesn't suffer the same problem.

-

@mrehorstdmd yeah I don't see how that would be possible. There's way less moving parts and no gears at all.

@tombrazier did you print mihaidesigns extruder test piece? I'd be curious whether any patterns show up there. -

I found a simple way to deal with the BMG gear issue, would be interesting to print the extruder test.

I added a screw to adjust the gear-mesh no matter how the tension spring is set.

Do you have a link?First I thought, I had to become patron, but he offers the test file for free on his HP

-

@o_lampe Interesting, do you have a picture of it in CAD? I'm not familiar with the sherpa, so it's hard to tell what I'm looking at

Thanks also for the link for the extruder test piece.

-

@nikscha said in Hollow shaft extruder:

I'd think that a bigger included angle actually makes grip worse. My train of thought is that Bondtech can get away with 90° because more than 1 tooth is engaged in the filament, and they choose 90 degrees because it holds up better against abrasive filament.

That was my expectation too - mainly informed by how grip works on ice skates. The closer to vertical the side of the blade is, the more grip there is. But the thread widening effect acts like a plough wheel. It's not grip that is the problem but rather that a furrow is being ploughed through the plastic. You can actually see this and it really does look like ploughed earth with a little ridge piled up parallel to the thread. I am now wondering whether different plough wheel profiles would have different ploughing effects. I notice plough wheels tend to be thin. So if I don't actually want to plough, what if I used a more wedged shaped wheel?

I'm surprised that you don't print faster with such a lightweight extruder. That seems to be the biggest advantage to me. What other reasons are there to use your extruder instead of the Orbiter for example? You mentioned something about ease of disassembly earlier I think?

I tend to prefer a maximum 0.15mm layer height and often print at 0.1mm and sometimes at 0.05mm. This needs fast X and Y movement but does not need high extrusion rates.

Ease of disassembly is also a feature I value.

The killer features for me were the steps/mm ratio and the simplicity. I started with a cloning a Prusa extruder which drives a pair of bondtech gears with no gearing and with a significant sideways force applied to the end of the stepper shaft, which adds a lot of friction. My recycled E stepper often just could not produce enough torque to drive this configuration. Then I played with a printed split ring orbital gear assembly which was wonderful when it worked but sometimes would start spitting out bits of gear tooth mid-print. In comparison the VDE-100 was extremely light, needed very little current so there were no heat problems and just works.

And, as @mrehorstdmd suggests, the VDE-100 eliminates the artifacts related to the bondtech gears and the step size of the E stepper.

did you print mihaidesigns extruder test piece? I'd be curious whether any patterns show up there

It's printing now.