TPU Shore 60A

-

@jens55 Thanks for the pics - I think I now understand how it works. It's not uncommon for compression fittings (which is what this is essentially) to leak slightly for as number of reasons. Have you tried the normal plumbers solution of wrapping ptfe tape around the threaded part? That's the first thing I'd try. In case you don't know what I'm talking about, here is a little video I found on how too apply it https://www.youtube.com/watch?v=efTqIIAfPhI

-

@deckingman, thanks for your thoughts. In this case, the threads have no sealing function whatsoever. Water is never supposed to get past the joint between the seal and the main body.

Having said that, I have confirmed that the surface on the printed seal is too rough to work. I have devised a few more tests to try a bunch of different things. One of these tests will be with a seal printed with ironing on in order to make the seal surface smoother. I will also use 0.1 mm layers instead of 0.2 mm layers which should reduce surface roughness. I should have tried ironing right at the beginning but just never thought of it.

I might have introduced another error during my testing and a whole bunch of experiments need to be repeated. -

@jens55 Yes, I understand what you are saying about the thread leakage - but talk to any plumber. In theory compression olives used in copper water systems should always seal but in practice they often leak. That's why plumbers almost always use PTFE tape on threaded connectors, even though the thread itself is not supposed to be part of the seal. It might not be the solution in this case but it will only cost a few cents to find out...........

Edit. When I used to use Diamond hot ends, many users complained of leakage where the heat sinks screwed into the brass part. In theory, the face of the heat sink should seal against the face of the brass part so it shouldn't happen. I always used to assemble mine with PTFE tape on the thread and never once had any leakage problems.

-

@deckingman, a lot of people have hot end leakage because they do not hot-tighten the tip which invariably will result in leakage at operating temperatures. If you hot tighten and still have leakage, that says "Chinese tip' to me

I know what you mean re plumbing but a lot of times we are talking a drip every few seconds compared to a geyser in my case. Independent of that, if I seal the thread, the same amount of water will escape out the central hole of the cap where the sprinkler pops up.

I am not concerned with a drip every second but when I have a string of sprinklers that are maxing out the water flow that the system is capable of supplying, when you loose a geyser's worth of water at every sprinkler head, you have no pressure left and the sprinklers reach will drop substantially resulting in green patches wherever there is a sprinkler head and brown patches where the sprinkler no longer reaches.Well, I have a number of tests to run and hopefully I will find a smoking gun (or leaking joint)

-

Further comment:

It REALLY doesn't help when you have a tiny particle lodged between the glass build plate and the aluminum base plate. That took way longer to find than it should have I think this particular issue has been present for some time and would have caused a lot of hair pulling if I had any hair left.

I think this particular issue has been present for some time and would have caused a lot of hair pulling if I had any hair left.

Tests with the sprinkler are ongoing and results will be reported for everyone's amusement <sigh> -

If you can, get one of these products:

Just print a mold, use some mold release, and you will make a perfect gasket.

I did not read the entire thread, but also make sure the 3d printed part itself is waterproof. Print it solid or dip it in resin after printing to make sure it's 100% waterproof. I made some critical parts and gaskets for a waterpump and it took me some trial and error before I made it 100% reliable.

-

@jens55 said in TPU Shore 60A:

@deckingman, a lot of people have hot end leakage because they do not hot-tighten the tip which invariably will result in leakage at operating temperatures. If you hot tighten and still have leakage, that says "Chinese tip' to me

For reasons that are beyond the scope of this thread, you can't hot tighten a Diamond hot end.

I know what you mean re plumbing but a lot of times we are talking a drip every few seconds compared to a geyser in my case.

Depends on the pressure - and you did say you have about 100 psi.

Although this is digressing somewhat, someone once told me the definition of an expert................ an "ex" is a has been, and a "spurt" is a drip under pressure. I always think of that when someone on TV is introduced as being "an ex spurt".

-

@deckingman ... LOL, got to remember that1

-

@omni said in TPU Shore 60A:

If you can, get one of these products:

Just print a mold, use some mold release, and you will make a perfect gasket.

I did not read the entire thread, but also make sure the 3d printed part itself is waterproof. Print it solid or dip it in resin after printing to make sure it's 100% waterproof. I made some critical parts and gaskets for a waterpump and it took me some trial and error before I made it 100% reliable.

Before ordering O rings for this project, I attempted to make a simple flat ring in a mold but had no end of problems. The RTV doesn't flow so I was unable to 'flow' the material into the mold. Forcing the material in will invariably result in some trapped air pockets. I did not get around to degassing the RTV in a vacuum chamber. I gave up on that before I went too far down that particular rabbit hole.

I think I would need to get some castable silicone material that flows properly and that stuff is quite expensive and has a limited shelf life (I think one year).

How did you manage to overcome these issues? -

@jens55 Well, with the rtv I just kind of overpoured it into the mold and made a mold in such a way that it squeezes out the excess... Then when it cured I just did a little bit of postprocessing with a scalpel / rotary tool. Don't know if there were any significant air pockets but it sure worked well enough, and going strong for more than a year now. The second one is pretty much liquid, you can pour it easily. I still haven't used it but it was recommended to me by a person who uses it regularly so I bought it as a backup option. Didn't yet need it since this rtv worked great.

-

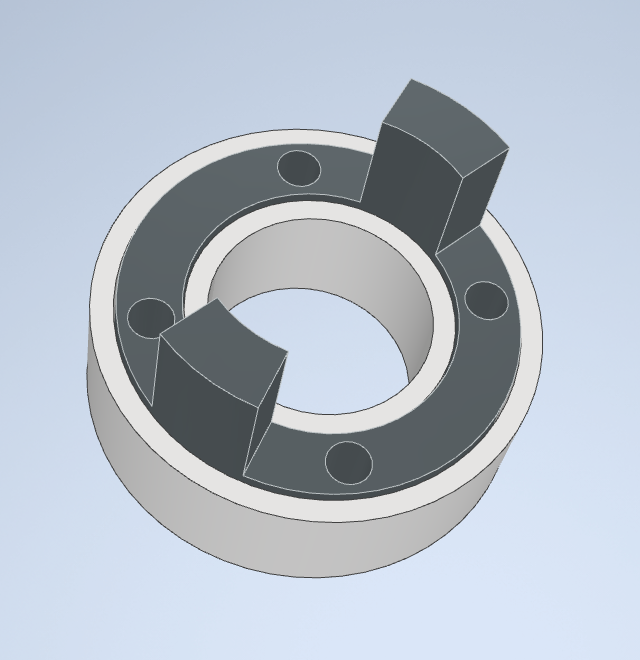

Can't find the original file for the gasket mold, but I skecthed something fast along those lines.....

Fill the light gray part with rtv, push the dark gray part inside, the excess goes out from the holes.... when it cures, you just cut it out with a scalpel.

But you need to do it fast while it's still viscous, since it cures quite quickly.... Also my gasket was rather large, so I guess it would be a bit difficult to squeeze it out if the holes were very small....

-

@omni, thanks. Interesting how you used a 'pusher' with holes. I will have to give that a try. I will also look for that other, more liquid material.

What did you use as a mold release? I didn't have anything specifically called 'mold release' so I used light oil. It might as well have been crazy glue

-

The idea was to put more material than needed (tighly packed into the mold straight from the tube) and then just compress it and let the extra material and and some air flow out of the holes.... It turned out great actually, just needed a bit of sanding where I cut the excess, but it's a 3 minute work.

For the mold release I used a puropse mold release wax (usually used for resin pouring) but since this RTV is silicone based, you can probably get away with a few drops of fairy dishwashing detergent spread all over, since silicone does not stick to it at all....

And one important thing, my mold was printed on a resin printer, so the tolerances were very tight and precise and the surface finish was excellent.

-

@omni Yea, another great thing about this method is that my gasket was actually quite complex - it had multiple points of contact on the lower side, so it was not a simple O-ring (more like a 3D o-ring) and I could not find a replacement anywhere. So you can make even complex gaskets.

I tried TPU printing, but anything below 70A is actually quite tricky to pull off nicely. especially if it's a bit complex, and there is always the seam issue with FDM, layers, tolerances, etc. For gaskets - printing a resin mold and using a purpose gasket compound is the way to go.... it also tolerates temperatures up to 200c, does not deform from water exposure and high pressure, etc.

-

Thanks for all the input! I have now figured out that ironing TPU causes a mess although maybe that could be lessened with adjusting the settings of the ironing process. I have also come up with a seal that actually works although that seal used PLA and an O ring for the seal and that will not work in the full functioning seal. I might try to build a composite seal that uses PLA and an O ring along the outside of the main body and TPU for the section that seals against the popup part. At this point I do not know how feasible/durable it is to combine PLA and TPU in a single seal when there isn't enough room to combine the materials with some sort of physical connection rather than depending on just adhesion.

Anyway, more trial prints are in order but progress is being made!After I have this all sorted, I will try my luck again at casting a seal based on what I learned here. I do have a resin printer that has been gathering dust and this might be a great excuse to give that printer another go.

I have given up on the thought of printing 60A shore TPU although I might still give a 70A material a try if I trip over a roll of it someplace up here in Canada. Most TPU in Canada is around shore 90A with only one vendor (that I have found) offering shore 60A TPU. I have not found anything in between those two grades.