Issues with pressure advance since RRF 3.4

-

Sorry for bumping such an old thread, but I think I am having similar issues. No matter what my PA setting is, I am getting buldging corners. Also @gnydick said "Right now, with even just a low poly curved surface, each segment is ~1.5mm long, I get a bulge at every direction change." This is something I, and some others have found to be a problem in this thread.https://forum.duet3d.com/topic/33692/input-shaper-causing-stutters-and-blobs-on-curves-rrf3-5-0-rc-1

Is PA smoothing something that may be impelmented any time soon? Is there any other fix for this?

I'm considering moving over to Klipper to see if I can solve some of the issues I'm having, but I really wish I didn't have to since I'm generally really happy with RRF on my Duet 3 Mini.

-

undefined Threepwood referenced this topic

undefined Threepwood referenced this topic

-

undefined Threepwood referenced this topic

undefined Threepwood referenced this topic

-

Just chiming in for visibility as I can also confirm to be noticing what appears to be PA oddities in regards to corner bulging, but also material deposition before and after a corner.

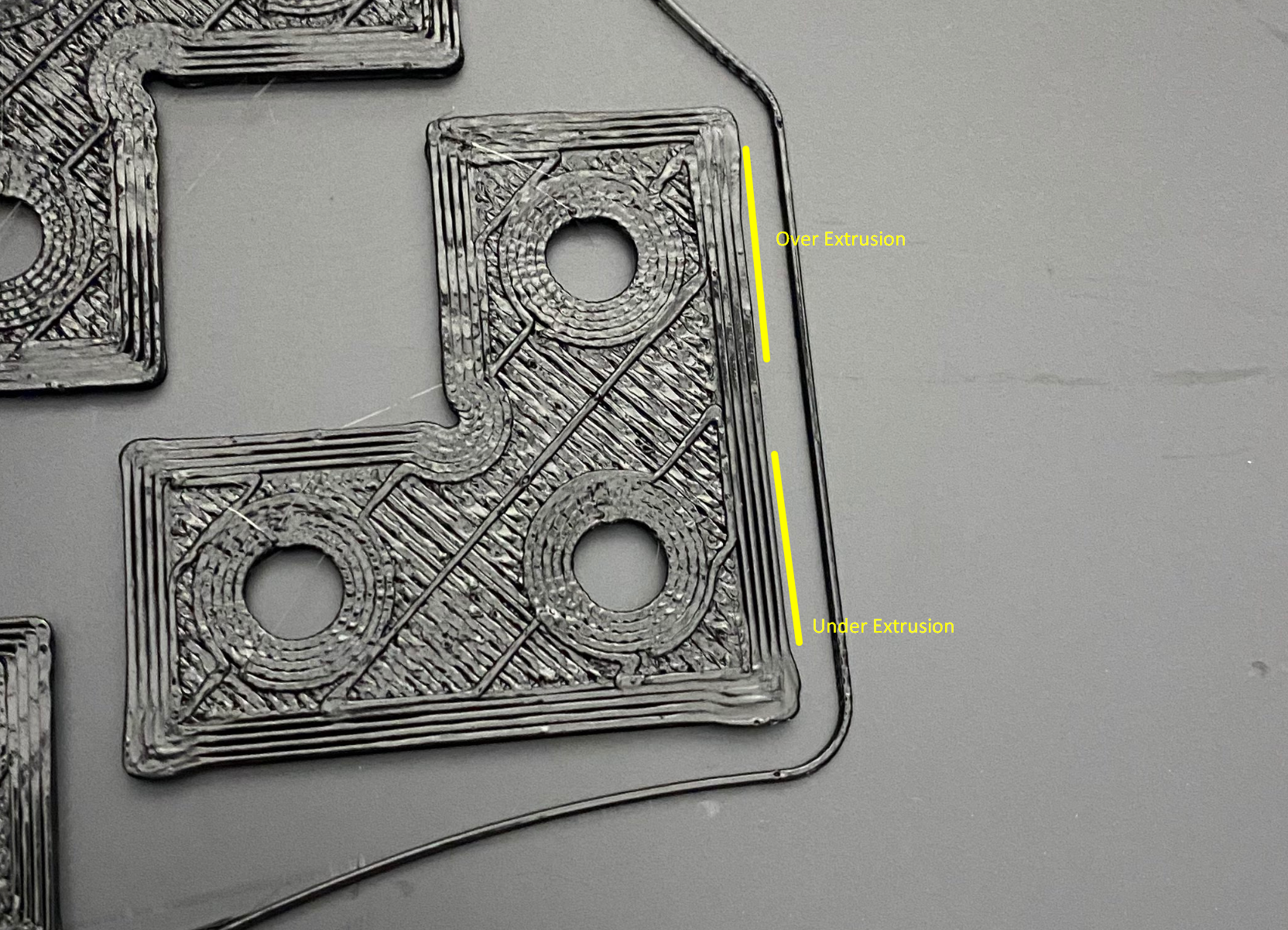

The hardware I use is a HemeraXS with a CHT 0.6mm Volcano nozzle with a InputShaper of EI2@20hz or EI2@48hz. Pictured is PA0.035

Pictured is PA0.035The issue is more noticeable with a 0.6 nozzle compared to the 0.4.

I need to use a PA value of 0.045 to get non bulged corners, however by doing so I get inconsistent extrusion before and after the corner.There appears to be a correlation with flow rate and the severity of the behaviour. When pushing flow rates (>35mm^3/s) close to the limits of the nozzle, the behaviour is at its worst. which makes sense as the pressure differential would be the greatest. What is puzzling is that the issue also appears in smaller parts where the flow rates are below 60% of the nozzle capacity.

I am currently using PA of 0.025 which is a middle ground of bulged corners and under/over extrusion.

I have not currently found any changes in this behaviour by changing the Input Shaper frequency nor shaper type

For extruder settings I was running a jerk value of 4mm/s (250mm/min) and an acceleration of 66mm/s2 (4000mm/min) - I am currently testing higher jerk and acceleration settings however data has been inconclusive so far -

@dc42 I don't mean to be a nag, but is there any chance PA smoothing (or similar) will be added to RRF in the near future?

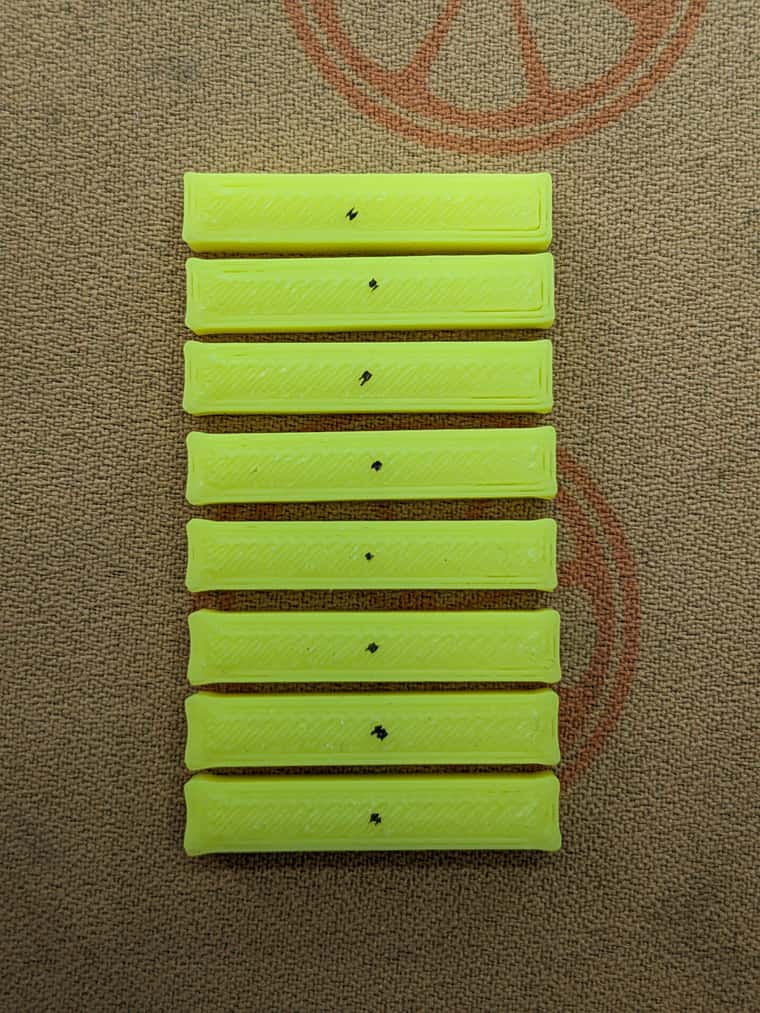

I've been trying to tune out corner bulging for days, changing just about everything I can and even buying a new nozzle, but I'm still not able to get a PA value that can remove the bulging without causing other extrusion problems in corners.

-

undefined Threepwood referenced this topic

undefined Threepwood referenced this topic

-

Something mechanical is going on here. PA works great for me on RRF. your issues are something else entirely.

-

@ctilley79 What makes you think that? I've been trying to fix this for days and I've checked everything I can think of multiple times. I'm really clutching at straws now. Open to trying other ideas.

-

Hi, I also struggle alot with PA calibration on direct extruder printers with Duet/RRF for a long time. I ended up measuring step signal of extruder to understand what is going on.

By comparing Klipper and Marlin PA, RRF appears to be completely different. There is very high pulse rate extra step signals at start and endpoints (and, I believe also in corners). For comparison, Marlin and Klipper appear to not insert extra step signals. @Threepwood could it be possible that your extruder is skipping steps during these high speed transitions?

Considering FW development, probably step signal measurement could be used instead of print testing, in that way testing is fast, and not dependent on the printer.

-

@petriheino Perhaps you could create a new thread and share your findings on the differences between the 3 firmwares when executing PA moves? I'm sure it would be of interest.

-

@gloomyandy Thanks for the suggestion, Ive been working on that and will probably release at some point, but I have only very rudimentary test equipment. Probably some testing could be done by Duet team to show that the RRF PA Algorithm is funtioning as intended and not affected by FW updates or configurations. This could help other developers to also jump in to possibly improve the algorithm.

-

@petriheino said in Issues with pressure advance since RRF 3.4:

@Threepwood could it be possible that your extruder is skipping steps during these high speed transitions?

No, it shouldn't be that. I'm able to extrude comfortably up to 30mm³/s with a 0.4mm CHT while printing and last night I even tried printing at 20mm/s XY speed (so 1.6mm³/s) for every print move with Ender 3 acceleration and jerk and I still got exactly the same corner bulging. This is using a VZbot hotend and extruder on a Voron 2.4.

-

@Threepwood skipping of steps could take less than 10 milliseconds, the motor movement amount involved could be miniscule and be hard to detect, and be non-dependant on other configs or print settings.

I had to connect another motor as extruder, connect a sort of clock dial to shaft, then did these short segment tests to see if motor returns to zero position Jetty Firmware Acceleration Test Scripts

This changed PA calibration cubes dramatically for me. Might be worth a shot.

-

@petriheino thank you. I've been trying for years to get some real testing done and not just "our code is proven correct, it's got to be sometime with your printer."

-

@Notepad I have a hemera and notice the same issues. I'm almost wondering if PA needs to be tuned at multiple hotend flowrates and then some linear interpolation applied to get the correct PA for the current flow rate

-

Quick update from my side.

I have concluded that this issue is definitely a filament behaviour / Pressure Advance component.

The largest improvement I have witnessed by tweaking every setting is to simply increasing the jerk value. I previously used a pretty conservative jerk of 4mm/s but with high accelerations 6000->12000mm/s^2. I have now changed the profiles to be of a much higher jerk 10->14mm/s with middling accelerations of 3000-5000mm/s^2.

This change overall has maximised the speed the nozzle can take the corners at, and thus has reduced the bulge amount considerably. The other change I have done is to manually change the STL files I use to round most corners by a minimum of 0.8mm in a bid to again, increase the overall speed the nozzle can take a corner at.

What I have found interesting during my testing is there seems to be a minimum jerk to acceleration ratio where if the nozzle cannot take a corner with sufficient speed. the outer layer quality on curved surfaces drops considerably (even with extremely high quality STL files and arc welder enabled). There is another thread that seems to be having the same issue: https://forum.duet3d.com/topic/33903/jerk-settings-at-different-speeds

Though, in order to keep this thread focused on the PA aspect (which I am now 100% certain there is) I will probably be creating a new thread for the Jerk/Accel behaviour oddities separately in the next few weeks while I gather more data.

-

My slightly modified Creality 5 pro prints FLAWLESS prints in ASA within +/- .03mm, and perfect corners every time, and has printed several hundred of these prints for two years now in numerous sizes and detail; with no PA or IS applied.

I wonder what the true problem is here…

If you’re relying on current software to fully tune out harmonic and flow issues of your printer, you simply need to slow down your outer perimeter print speed and accept the limitations of your printer.

Without a full feedback loop of accurate algorithms, no current software will be able to adjust for all conditions and provide the accuracy that people seem to think is expected. What is happening instead is we turn into the feedback loop and chase countless inconsistencies.

You will be more successful and efficient resolving resonance/pressure issues by improving the physical design of the printer than you will be expecting software to resolve it.

I’ve been fighting this shit for over a year now, and I’m tired. I’ve finally figured out that simply slowing down outer perimeters, turning down PA and turning off IS & optimizing outer perimeter jerk/accel/speed gives me the best and most consistent print and I don’t need to re-tune for every nozzle size or material. Yes, its slower. Its also much less filament/nozzle dependent and more consistent. I can still print infill and supports at insane fast speeds to cut down on time.

If you really want super speed, buy a Bamboo and deal with their proprietary bullshit.

-

Im not entirely sure what point you are trying to make here. But its definitely not on topic, nor is it helpful to identifying the cause and effect which causes these surface irregularities.

My slightly modified Creality 5 pro prints FLAWLESS prints in ASA within +/- .03mm, and perfect corners every time, and has printed several hundred of these prints for two years now in numerous sizes and detail; with no PA or IS applied.

Im happy that your machine works flawlessly for your use case and speed requirements, however this is the equivalent of saying "it works on my machine so it should work for yours"

A CR-5-pro is an entirely different class of machine compared to most people who are having issues. And comparing a Bowden system to a Direct Drive is already a stretch.If you’re relying on current software to fully tune out harmonic and flow issues of your printer, you simply need to slow down your outer perimeter print speed and accept the limitations of your printer.

The issue most of us are having is not flow issues, its flow control issues. I can happily print my outer walls at 100mm/s using only 30% of my nozzles max flow, but the issue still persists. Thats because its not directly a speed or flow rate problem. The issue still exists at 60mm/s or 40mm/s.

Just making a post about how "slow your machine down and you'll be fine" just derails the entire conversation and the research and identification that the other users in this thread are documenting.You will be more successful and efficient resolving resonance/pressure issues by improving the physical design of the printer than you will be expecting software to resolve it.

If you have any advice to give I would gladly welcome it. I am currently using a Hemera XS with a copper heat block using a CHT Volcano nozzle. I would like to think that my choice in nozzle, extruder and tertiary materials are all aiding in making a better printed output. I would expect most people in this chat are probably using different extruders, with different nozzles from various brands and qualities.

If you really want super speed, buy a Bamboo and deal with their proprietary bullshit.

I hope its not just me, but I find this defeatist attitude extremely offensive towards all the hard work Duet have been putting in to making their ecosystem, to any advanced user (Voron, VZbot, Etc) who spent lots of time and money to make a fantastic machine, or even to the other companies like Bondtech or E3D with their high flow hot ends or parts designed for higher grade machines than your creality 5 pro.

Your response is just "buy a Bamboo and deal with their proprietary bullshit".

Im sorry if this comes across a bit ranty, and you are correct in your statement that without full feedback, no software will be 100% able to compensate for every situation, but that doesn't mean we shouldn't try. Trying to improve stuff with the community is pretty much the definition of Open Source and everyone here is documenting their experiences in a bid to help reduce or mitigate the issue.

-

Now that some steam has been blown off hopefully we can get back to the issues at hand. Thank you to all participating in finding the cause of the issues.

-

Not sure why you seem to be so offended as my comments were not even a reply to your post specifically. I guess that is what the internet has become these days.

I feel it absolutely is on topic. The entire industry right now is using printing and movement speed as a selling point to their machines, and this entire topic is based on software algorithms that are implemented SOLELY to improve printing speed. My Creality 5 Pro is not a Bowden machine, as you assume. It is also only one of four printers that I own. I only use it as an example because it is the one machine that prints consistently with zero corner issues or resonance with zero PA or IS applied and it does this due to the specific reasons that I highlighted.

I have been tuning my Duet-based CoreXY printer for a very long time, using and implementing just about every approach possible, and with each approach, it always comes back to the same basic principle, which I adequately highlighted. Software is not going to make a machine faster when it has specific analog traits and limitations that vary beyond the capability of the software. Yes, it is fun to try, and yes, I can find one or two prints and apply a limited amount of IS and PA and eventually get them perfect... But when I go from a .6 to .8 nozzle and an entirely different material viscosity, or even filament brand... guess what... I need spend another 6 hours tuning IS, flow rate, PA, ect. to get that next print perfect, or I can just slow down and print it in 4 hours instead of 2 or 3 and already have been done with the print. Perhaps my view from a business owner standpoint is different because time to me is money.

You can try and speak for Duet all you want and become offended over some words. Quite the contrary to a defeatist attitude; my sole point is that one should be well aware of the limits of their machine and manage their expectations accordingly. The Bambu comment was because I actually am on loan with one right now to test and study. I am not a fan of proprietary machines, and never have been. The requirements of my business are well beyond the size capabilities of a Bambu. I do feel like they have gotten a few things right because this machine indeed uses feedback to adjust for changing analogous conditions per print and per material and the results are quite evident.

I can assure you the Duet engineers are studying the same technology as well and doing their best to determine future implementation. The bigger burden is on the Duet engineers to design an open source software that works across any machine, which of course is a much greater challenge, and I have nothing but commendation for Duet, Dave Crocker, and the hard work they have put in to meet customer expectations to date. I would not be in a Duet forum with over a thousand dollars invested in numerous Duet boards if I was not a huge fan of both their product and their work.

-

https://forum.duet3d.com/topic/33803/unable-to-stop-severe-bulging-in-corners-with-new-print-head/29

The same issue in above link too.

-

Most likely it is obvious on CoreXY machine. When there is a corner, and moving before arrived the end of corner, both A motor and B motor, need to slow down, severe bulging will come before arriving the corner. If it is the machine like UM, it will be only severe bulging after corner but never before corner, as there is only one aixs motor for each aixs. However this is the inherent feature for CoreXY, due to it needs both A motor an B motor keep moving.

This is the first time I am using CoreXY machine, the E3D ToolChanger.

No clue how to fix it...

What I guess, PA can't fix this, as it is XY movement related, not extrusion related. However the Input shaping is the direction. RRF Input shaping is still the blackbox, a long way need to go.

-

Adjust the belt tension can not fix the problem.