PLA keeps geeting stuck

-

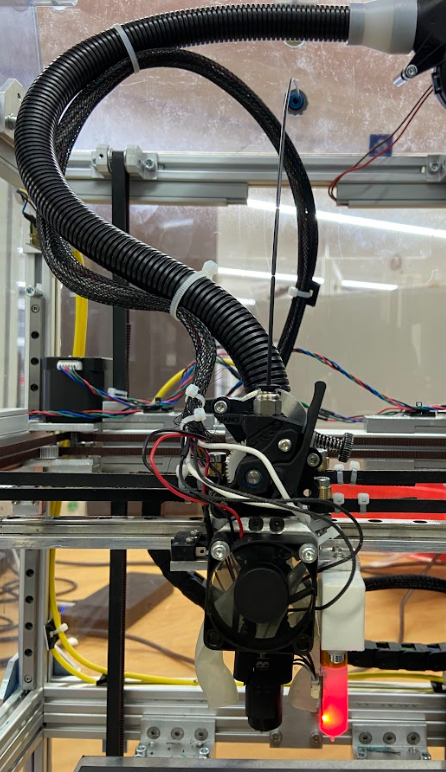

Hi, i´m trying to get my Printer to run with PLA, since I did the first prints with ABS and TPU. These two Materials worked perfectly fine but when I change to PLA there´s a Problem. Small Parts work perfectly fine, but if I try to Print bigger Parts, after some time, the Material keeps getting stuck. The Nozzle isn´t clogged and i tried with different Temperatures, Speeds, etc. which didnt help. I also changed way it feeds the Material to the extruder, no change. After it stoppes extruding (Extudermotor keeps turning) it wont even retract. I have to pull the Filament out with force. Any ideas? Thanks

-

make sure that the hotend fan blows onto the heatsink. Also make sure to minimize retraction; your setup should be good for retracts below 1mm (I'd probably try with 0.4 and then fine tune).

-

@Tobi_innit For PLA you'd need a heatbrake with PTFE insert. ABS can work with an "All-metal" heatbrake.

Maybe you have the right heatbrake, but the PTFE-tube coming from the extruder isn't pushed down far enough?

-

@o_lampe I print PLA for years with all metal heat breaks. PTFE heat breaks are obsolete.

-

@oliof @Tobi_innit it also looks like the PLA is pretty chewed up from lots of retracts, it may help to reduce tension on the idler arm and is another indicator that reducing retraction may help.

-

@Tobi_innit As other have alluded, your problem is heat creep beyond (above) the heat break. The reason it affects PLA and not other filaments is because PLA has a lower glass transition temperature. So pressure from the extruder will cause it to swell and eventually block the heat break. That causes the extruder too grind away the filament which is why you can neither extrude nor retract. The solution is to keep the incoming filament (above the heat break) colder. Things to avoid are keeping the hot end heated with no filament moving forward. Also, (as other have said) retracting too much filament will pull molten material up into the heat break where it will cool and solidify. Dropping the extruder temperature as low as you can get away with will also help. Increasing the air flow over the heat sink (e.g. a more powerful fan) is also something to try. If you have an eclosed chamber, do not heat it and leave the doors open.

-

@deckingman Reducing extrusion-temp would be the last straw IMHO.

I like to print a bit on the hot side and use obsolete PTFE heatbrakes to avoid heat creep. That allows higher extrusion rates and reduces the risk of underextrusion.

I guess, All metal heatbrakes have to be top quality? (Throat polished or reamed?) and the (bigger) hotend fan would run at 100%.

I use 40x10mm fans at 60%-80% speed, they are quiet enough to sit in the same room. -

@o_lampe To a certain extent, some heat will conduct up through the filament itself. Which means that no matter how good the heat break is at reducing conduction through the metal you can still get heat creep through the filament itself. This is not normally too much of a problem providing the filament is constantly moving forward. Your PTFE liner doesn't stop this heat creep - it merely gives a low friction surface so the semi molten filament doesn't stick. The big downside is that PTFE itself will start to degrade at circa 200 deg C so you can print PLA but nothing much else. The OP has already stated that he prints ABS and TPU so a PTFE lined hot end isn't an option for him.

Printing PLA at higher temperatures has it's downsides as well as upsides. At the start of a print as the hot end is heating, there will be some heat creep through the filament itself because the filament is static. So the higher the print temperature, the longer this initial heating will take and the more the PLA will soften in the area of the heat break, and the higher the likelihood of jamming once the extruder starts to push on the filament.

-

@deckingman it really seems to be a matter of construction; I can't say that I had heatcreep related issues even with PLA sitting in the hotend at 230C for half an hour to an hour. But then I don't worry about my 4010 hotend fan noise levels (either by virtue of a lack of good hearing, or because other components of the printer quickly drown out the fan noise as soon as it is printing).

@o_lampe I would say all commercially available all-metal heatbreaks these days come with smooth insides, the early reprapped all metal heatbreaks required more care. But the slice copperhead inspired bimetallic heatbreaks with surgical tubing pressed into copper threads or Ti5.5 based all metal heatbreaks all are smoother than a baby's butt (that's a technical term).