Implementing a custom code in the G code

-

@Muhammed I'd suggest that you split this move into two parts, one part of the Z move, one for the X/Y move:

G0 F9000 X50.0 Y117.5 Z30.0The speed of the move will probably be limited by how fast your Z axis can move (compared with your X and Y axis). But more importantly there is a danger that you will scrape your printhead over the print (assuming that Z=30 is below the max height of your print). If Z=30 ia above the max height of any print then I suggest you do the Z move first followed by the X/Y move, if Z=30 can be below the max height of the print then do the X/Y move first followed by the Z move.

-

@gloomyandy Many thanks for your reply. Actually, I tried to split the Z move before X and Y but the speed still stays slow no matter what the

Fvalue is. Also, yes I am considering Z=30 as the max height of any print. I will give it a try again as you mentioned. -

@Muhammed said in Implementing a custom code in the G code:

the speed still stays slow no matter what the F value is

The speed limit for the axis from config.g may be set lower than your requested F value?

-

@Phaedrux I have the following values in my config.g file:

M566 X1200.00 Y1200.00 Z24.00 E300.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1500.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z100.00 E1000.00 ; set accelerations (mm/s^2)I see

M203 Z180?!

I chose these values for Ender 3 printer from its Github page! do I need to modify them?Thanks!

-

@Muhammed said in Implementing a custom code in the G code:

I see M203 Z180 ?!

That's pretty slow. 3mm/s

How fast are you trying to move the Z axis? What F value are you trying to use?

I'd bet you get increase that value to M203 Z600 which would give you a maximum of 10mm/s. If that's too much, back it off a bit.

-

@Phaedrux I understand now.

I don't have specific speed requirement for now, but definitely not 3mm/s. This was the recommended speed by Creality for this printer. Would it be ok for the printer if I increased it to 600?

Thank you all. -

@Muhammed it's pretty difficult to give a definite answer on the maximum speed on an ender 3 because there are so many (unnamed) revisions and the build quality is highly variable, including questions about how square the Z axis drive is. If your ender 3 is in good shape, it should be able to do 10mm/sec (so your 600 value). In the end you'll need to do some experimentation to find the actual limit of your machine.

-

@oliof Thanks a lot for the valuable feedback, I will try that carefully and see how the printer will response.

-

Hello everyone, Thank you all for your support up to this point. It seems that putting the slicer in relative extrusion mode is giving better results, and the code below is working just fine:

G1 E-5 ;Retract the filament slightly G4 S0.3 ;Wait for 3 millisecond G0 F5000 X20.0 Y117.5 Z40.0 ;Move to a reference starting point G4 S0.1 ;Wait for 1 millisecond G1 F9000 X200 ; Move the X-axis to the endpoint G1 E5However, after this code executes, the printer’s head returns from the Z40 height to start the next layer, but during this, a bit of filament is melting from the nozzle and affecting the print. Is there any way to adjust this?

Thanks!

-

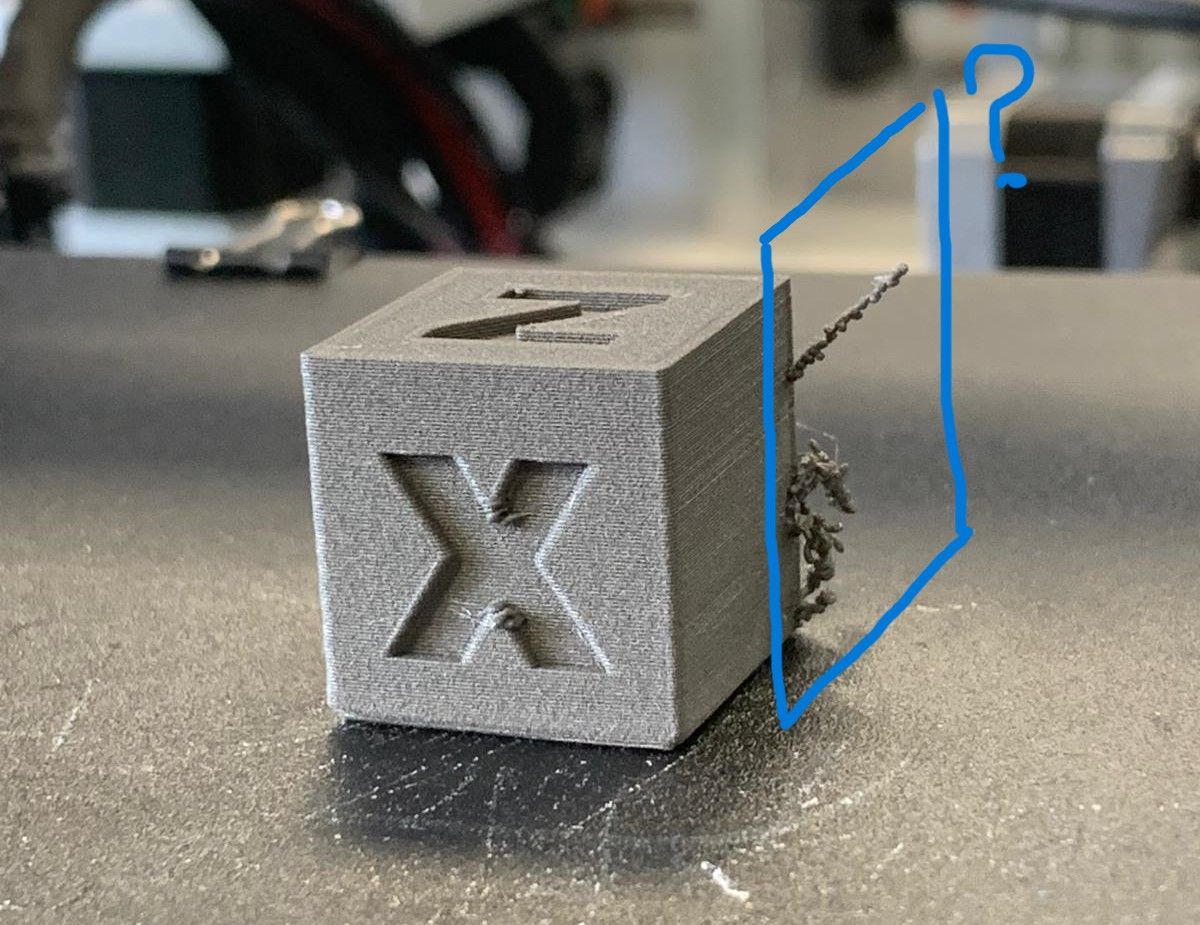

@Muhammed This is the current output while the above code is implemented during the printing process.! Is there anything I can do for improvements?

-

@Muhammed That looks like oozing from the nozzle as it goes off the print, then attaches like that when it comes back to the print. I think this is caused because you retract 5mm when you move off the print, but extrude 5mm before you move back to the print, so the melted filament has time to ooze out as it returns from X200 to the print.

You could save the position at the point your retract with

G60 S0(see https://docs.duet3d.com/en/User_manual/Reference/Gcodes#g60-save-current-position-to-slot), then move back to this after the move along the X axis withG1 R0 X0 Y0 Z2(see https://docs.duet3d.com/en/User_manual/Reference/Gcodes#g1-controlled-linear-move), then extrude 5mm, so you are where you left off before extruding. The 'Z2' means the nozzle comes back to the point 2mm above saved position.So you code would look like:

G1 E-5 ;Retract the filament slightly G60 S0 ; Save position to slot 0 G4 S0.3 ;Wait for 3 millisecond G0 F5000 X20.0 Y117.5 Z40.0 ;Move to a reference starting point G4 S0.1 ;Wait for 1 millisecond G1 F9000 X200 ; Move the X-axis to the endpoint G1 R0 X0 Y0 Z2 ; Restore position G1 E5You may end up with a small bulge if it starts on the perimeter; you could offset the restart position into the print by a couple of mm in X and Y, to wipe the nozzle inside, as it restarts.

Ian

-

@droftarts I really appreciate your support and thanks a lot

. This solved the issue perfectly.

. This solved the issue perfectly. -

undefined Phaedrux marked this topic as a question

undefined Phaedrux marked this topic as a question

-

undefined Phaedrux has marked this topic as solved

undefined Phaedrux has marked this topic as solved