Hollow shaft extruder

-

@o_lampe Veritas Streichmaß or DICTUM Streichmaß and "veritas streichmaß ersatzmesser"

There is also one with assembled adjusting ring on https://www.feinewerkzeuge.de/veritas-marking-gauges.html, "VERITAS Schneidräder für Zapfen" but it's a bit expensive (22 EUR), but maybe one can DIY.

-

@JoergS5 Very interesting. The idea is to bulk-buy instead of DIY.

IMHO the biggest problem with Toms handmade bearings is to keep the diameter constant. -

Veritas tools are nice, but not cheap.

https://www.axminstertools.com/veritas-wheel-for-marking-gauges-477717 is a UK retailer.

The company is Canadian: https://www.veritastools.ca/en-ca/shop/tools/hand-tools/marking-and-measuring/marking-gauges/59455-veritas-standard-wheel-marking-gauge?item=05N3321 and the wheel is https://www.veritastools.ca/en-ca/shop/tools/hand-tools/marking-and-measuring/marking-accessories/102171-replacement-wheel-for-veritas-standard-wheel-marking-gauge?item=05N3511

-

@achrn Thanks for the links, but in the canadian closeup picture it looks horrible. I don't see, how it would rotate nicely.

-

@o_lampe I believe the entire shaft rotates, not just the cutter.

-

@Phaedrux Possible, but I checked the video again and he adjusts the shaft-depths and locks it with a thumbscrew.

So either it's a rotating shaft in a fixable tube, or the screwhead doesn't fully clamp the blade and acts as a bearing, too.

Both ways wouldn't be easy to adapt to a blade-extruder. -

On the Veritas tool, neither the cutter nor the shaft rotates during use. The cutter scribes the wood, and the shaft is rotated to a new cutter edge position when and if the cutter becomes dull.

The screw just holds the cutter firmly on the end of the shaft. The cutter is not supposed to rotate at all.

-

@rqthree So it's probably not 100% round, because it's not relevant for the actual usecase?

I think, we have to look elsewhere then. The blade extruder only has a commercial future, when we find a way to build it economically.

For the rotor body to be adjustable to the blade diameter, I thought of an arrangement like this:

Three individual bodies which are held together with an O-ring to provide adequate pressure.

[Picture curtesy of RC-network} -

No activity for quite a while, but if anyone is still interested, here's a source of carbide cutter wheels. The V500 looks of particular interest, and they can manufacture to spec:

https://www.fletcher-terry.com/frame-joining-cutting-hanging-automation-1/carbide-cutting-wheels

I'm still using my original ground flanged steel bearing from 3+ years ago, and all is well

-

@rqthree Nice find!

I started looking for a wood lathe and the turning tools I'd need and guess what I've found:

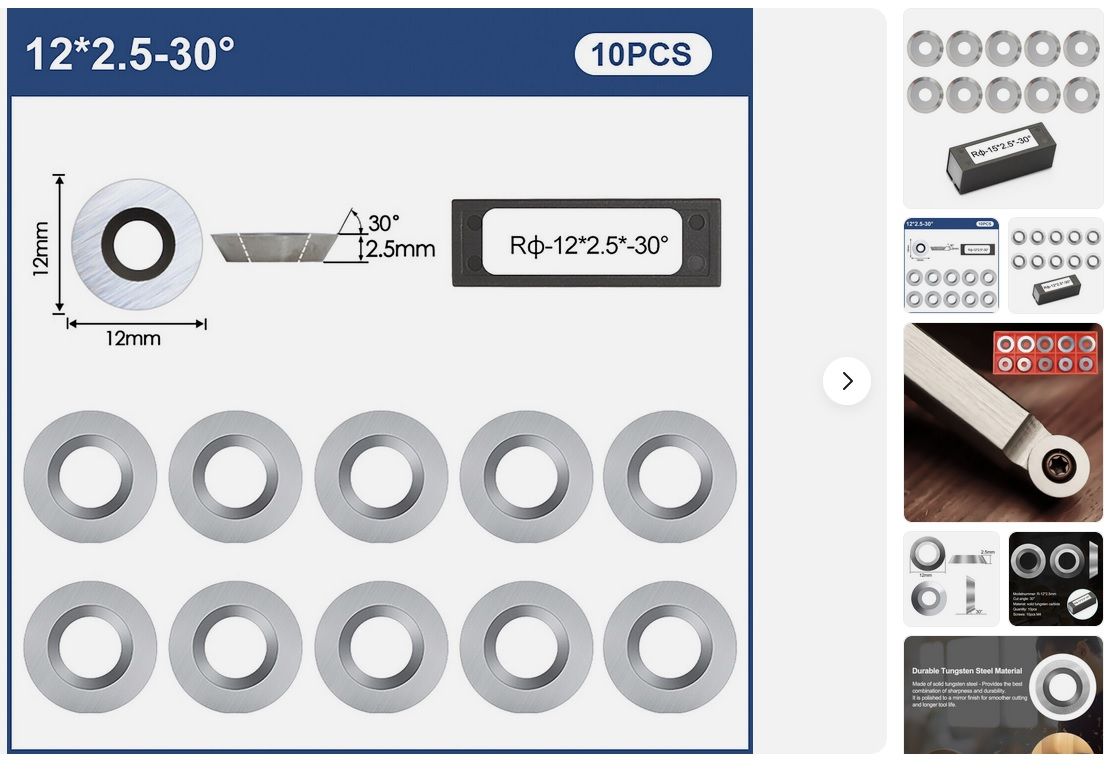

Wood turning Tungsten carbide round cutter

They come in different sizes from 8.9mm to 16mm dia. A set of 10pcs is ~18€ which would be a lifetime supply for our usecase

-

@tombrazier , mayby a silly question but what rpm are you using when grinding bearings on your rotary tool? I was trying with 10k rpms and 2 bearings are not usable already. Not sure that it is because of the speed and now I am tweaking the jig but I'd like to know anyway.

-

undefined o_lampe referenced this topic

undefined o_lampe referenced this topic