Homeall.g fails when homing all axes

-

You are using H2 instead of H1.

You posted that the X endstop is at the low end.

I don't know how long the X axis is but you need something like...

G91 G1 H1 X-999 F5000 ; use a value large enough to move the entire length of the X axis G1 X10 G1 H1 X-15 F500...then based on what the physical position is when stopped by the endstop being triggered

G1 Xnnn ; move to some known position on the axis - note this is a relative move still G92 Xppp ; set the X axis logical position to match the physical positionFrederick

-

@fcwilt

X-axis = 340 mm and Y-axis = 447mm.I think i only have extra additional of -2.0516mm on X-axis on the low end and -4.0244mm on Y-axis

-

@developeralgo222 said in Homeall.g fails when homing all axes:

@fcwilt

X-axis = 340 mm and Y-axis = 447mm.I think i only have extra additional of -2.0516mm on X-axis on the low end and -4.0244mm on Y-axis

OK then your first G1 H1 move would be

G1 H1 X-345 F5000You can pick a speed (the F parameter) that works best for you - it's not critical but you can go too fast.

At what position does the X endstop trigger? Are you treating that as X=0?

Frederick

-

@fcwilt said in Homeall.g fails when homing all axes:

At what position does the X endstop trigger? Are you treating that as X=0?

Yes at X=0. Do i need to test this on the command console or just put them in a homing file and test on DWC ?

something like this on homex.g ?

G91 G1 H1 X-345 F5000 ; use a value large enough to move the entire length of the X axis G1 X10 G1 H1 X-15 F500 G1 X0 G92 X0 G90 -

@developeralgo222 said in Homeall.g fails when homing all axes:

As I mentioned if the endstop triggers at the end of the axis travel and you are treating that as X=0 then you don't need the following:

G1 Xnnn G92 XpppThey are ONLY needed when the endstop is not triggering at X=0

In your case this should work for you:

G91 G1 H1 X-345 F5000 G1 X10 G1 H1 X-15 F500Now if you have specified your X axis with M208 -170:170, meaning X=0 is at the center of the axis you could add the following:

G90 G1 X0 F5000 -

@fcwilt said in Homeall.g fails when homing all axes:

Now if you have specified your X axis with M208 -170:170, meaning X=0 is at the center of the axis you could add the following:

i have M208 X0:340 Y0:447

-

-

@developeralgo222 said in Homeall.g fails when homing all axes:

i have M208 X0:340 Y0:447

That is fine - you don't have to have X=0 at the center of the bed. Some folks just prefer it that way - I am one of them.

Frederick

-

@fcwilt

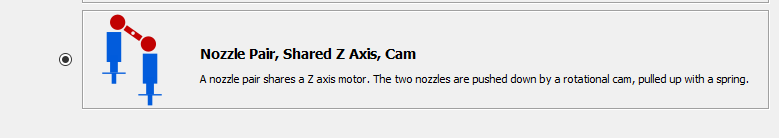

That worked for X &Y and Z , i am going through all the axes one-by-one following your insights .How do you configure the endstops of a shared z-axis cam based

i have to configure endstops for 6-Nozzles ( 2 Nozzles share a single Z-axis based Stepper motor ) so that they trigger correctly

i.e 3 Stepper Motors for Z, U, V axis but each axis shared with 2 nozzles each with a Z-axis type.

-

@developeralgo222 said in Homeall.g fails when homing all axes:

How do you configure the endstops of a shared z-axis cam based

i have to configure endstops for 6-Nozzles ( 2 Nozzles share a single Z-axis based Stepper motor ) so that they trigger correctly

i.e 3 Stepper Motors for Z, U, V axis but each axis shared with 2 nozzles each with a Z-axis type.

That is not a setup I have seen or heard of.

Does the "Z stepper" turn the cam to raise/lower the nozzle?

Does each nozzle have it's own endstop sensor?

Frederick

-

@fcwilt said in Homeall.g fails when homing all axes:

Does each nozzle have it's own endstop sensor?

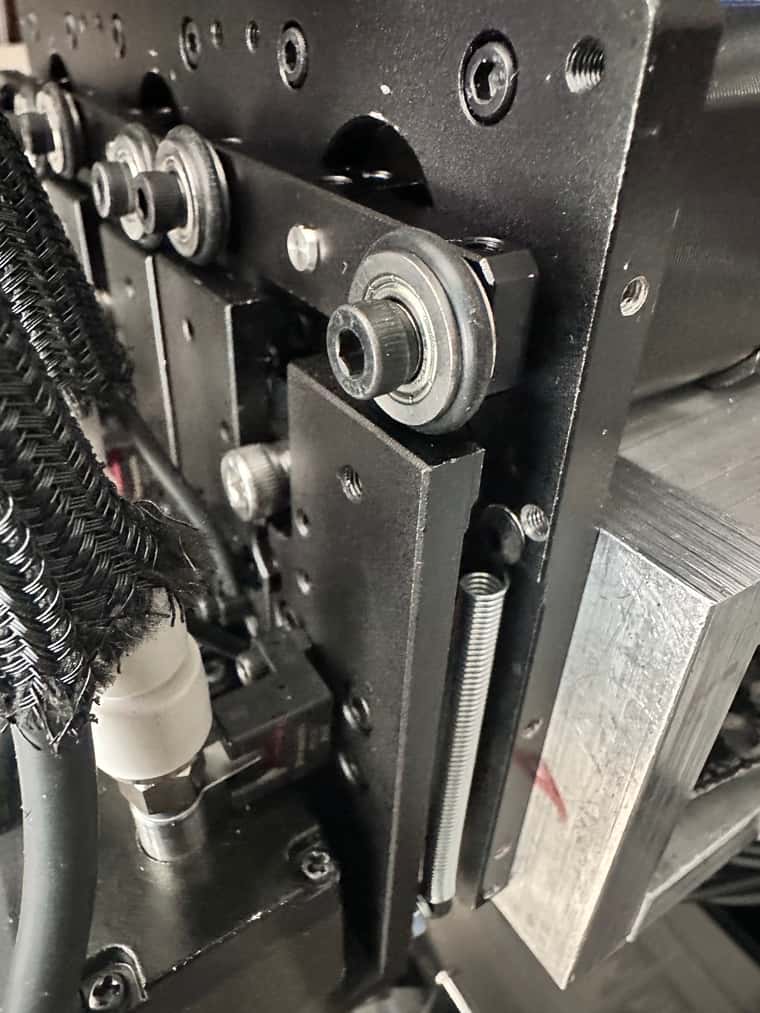

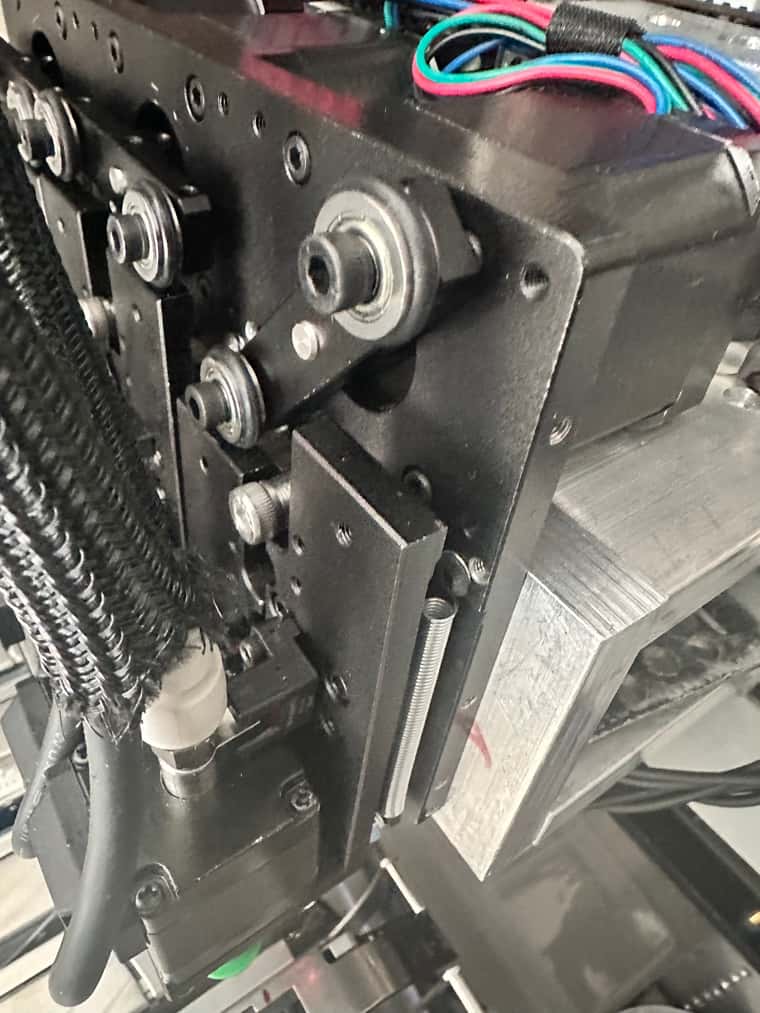

Yes, Each Nozzle has its own endstop . With CAM kind of shared axis when it moves down 1 nozzle the other stays at zero or is lifted back to zero point by the spring to where there is a stopper to prevent it from flying over.

-

@developeralgo222 said in Homeall.g fails when homing all axes:

Does each nozzle have it's own endstop sensor?

Yes, Each Nozzle has its own endstop . With CAM kind of shared axis when it moves down 1 nozzle the other stays at zero or is lifted back to zero point by the spring to where there is a stopper to prevent it from flying over.

OK.

Since you are using NPN sensors the outputs pull the inputs they are connected to to ground (GND)

I'm assuming only one of the sensors has the beam of light blocked when the nozzle is down.

If I am reading the spec sheet correctly the white wire is pulled to ground when the beam is blocked.

If so, you would want to connect both of the white wires to the Duet input and use the ! prefix character to treat the low input signal as active.

As before you would have a G1 H1 move in the direction of the sensor.

Are these nozzles simply up or down OR do they move over a range of vertical travel?

Frederick

-

@fcwilt said in Homeall.g fails when homing all axes:

Are these nozzles simply up or down OR do they move over a range of vertical travel?

They move over a vertical range of travel actually from 0 to -/+ 70 before they trigger the endstop . all have a range of -90:90 but technically

so

(1) On Z-Axis Motor , Z1 has a move range from 0 to -90 and Z2 has a move range from 0 to +90. When one is down , then other is always at zero

(2) On U-Axis Motor , Z3 has a move range from 0 to -90 and Z4 has a move range from 0 to +90. When one is down , then other is always at zero

(3) On V-Axis Motor , Z5 has a move range from 0 to -90 and Z6 has a move range from 0 to +90. When one is down , then other is always at zero

-

Thanks, that makes things more clear.

The homing code should be pretty much the same as before, though I don't actually know how the firmware handles two endstops.

How do you convert stepper position to nozzle position?

Frederick

-

@fcwilt said in Homeall.g fails when homing all axes:

How do you convert stepper position to nozzle position?

its just Z-axis as any other , no difference .The CAM on the motor just moves or rotates clockwise or counterclockwise to move the nozzles on the Z-based axes up or down

-

@developeralgo222 As each endstop is triggered at the end of movement for each nozzle, I would think you are best off redefining the endstop when a different tool is requested, followed by a move to trigger that endstop. eg something like

; home Z1 M574 Z1 S1 P"1.io0.in" ; configure active high endstop switch for low end on Z via pin 1.io0.in G91 ; Use relative positioning G1 H1 Z-180 ; go to endstop G90 ; Use absolute positioning; home Z2 M574 Z2 S1 P"1.io1.in" ; configure active high endstop switch for High end on Z via pin 1.io1.in G91 ; Use relative positioning G1 H1 Z180 ; go to endstop G90 ; Use absolute positioningI'm not sure how this would interact with OpenPNP, though.

Ian

-

@droftarts said in Homeall.g fails when homing all axes:

I'm not sure how this would interact with OpenPNP, though.

this is where i am also having doubts how that would work with OpenPNP

-

@developeralgo222 How does OpenPNP enable a tool? If it uses tool commands, eg T0, T1, T2 etc, then you can put the above code in the tpre#.g tool change macro. See https://docs.duet3d.com/en/User_manual/Tuning/Tool_changing

Ian

-

I would get it working directly and then see how that translates to OpenPnP

-

FYI,

this method doesn't work on both Duet and OpenPnP. Only one end point is active & can be triggered on the shared axis Z, U or V. I am not sure how to configure this is Duet3 for it to work.

Can someone help on this ?

i have 1 motor for each CAM shared Z-type axis . i.e 3 Axes ( Z , U , V ) each with its own Motor controlling the shared axis with Nozzle pair

Z-axis is shared between CAM Z1 (Has an Endstop1 & Nozzle 1 ) & Z2 axis ( Has an Endstop2 &Nozzle 2)

V-axis is shared between CAM Z3 (Has an Endstop3 & Nozzle 3 ) & Z4 axis (Has an Endstop4 & Nozzle 4)

V-axis is shared between CAM Z5 (Has an Endstop5 & Nozzle 5 ) & Z6 axis (Has an Endstop6 & Nozzle 6)

Z , U , V ( Z-Axis = (Z1, Z2), U-Axis = (Z3, Z4), V-Axis= (Z5, Z6) ) only Z2 , Z4, Z6 triggers Z , U , V respectively but not Z1, Z3, Z5

They move over a vertical Z-based axis range of travel actually from 0 to -/+70 degrees before they trigger the endstop . all have a rotational range of -90:90 but technically

so

(1) On Z-Axis Motor , Z1 has a move range from 0 to -90 and Z2 has a move range from 0 to +90. When one is down , then other is always at zero

(2) On U-Axis Motor , Z3 has a move range from 0 to -90 and Z4 has a move range from 0 to +90. When one is down , then other is always at zero

(3) On V-Axis Motor , Z5 has a move range from 0 to -90 and Z6 has a move range from 0 to +90. When one is down , then other is always at zero