Custom toolboard + duet wiring limitations

-

@SamKudarauskas I would just take the power directly from the PSU and then make sure you don't exceed the mosfets switching capability for each out connection you're going to use to switch load.

and a separate cable would be a better idea. I've been able to run an accelerometer with a 2.7m USB3 cable. you may get away with a ribbon cable -

@jay_s_uk Why is taking the +24V from a main line rather than from the dedicated +24V pin for each component run the risk of blowing the mosfet? What is the current limit on the mosfets and is my wire simplification idea worth it if I run the risk of damaging the board? What kind of precautions could I take to just use the +24V from heater 1?

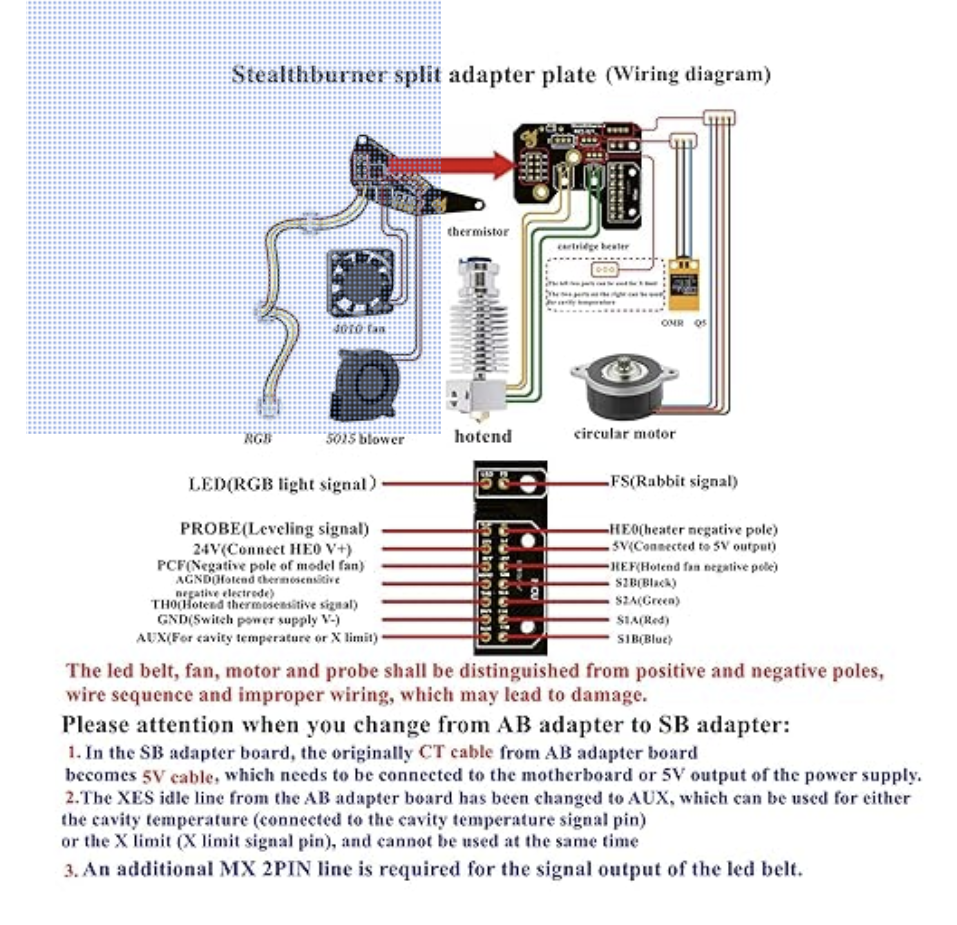

Also, I probably should have mentioned this earlier but I was inspired by this:

Edit: link to part here

On this stealthburner part it appears that they hae done some sort of wire simplification since it looks like they have more things connected to the board then wires running back to the main baord and I wanted to do something similar.

Edit: The stealthburner part has pins labeled +24V (connected to heater 0 V+), +5V and GND which appear to have multiple things connected to it. Hence where my idea to simply the wiring came from.

-

What is the mosfet switching capacity of the fan GND pins? Is it rated to handle the current that heater 1 outputs? If it is, would that be the simpliest way to simplify the wires and feed +24V to heater 1 and both of my fans?

-

@SamKudarauskas i meant to reply to you before.

The heater outputs on a mini 5+ can handle 5A switching loads each (out 1 and out 2) and the rest of the outs (out 3 - out 6) can handle 2A switching loads per output, all at 24V.

So as long as whatever you're switching (heater or fan etc) is less than those values each you'll be fine.

If you take the supply from out1, the maximum onboard 24v output current is 10A, that includes steppers etc which is why toolboards etc are usually wired directly to the PSU with their own fuse.

Are you looking to replicate the stealthburner setup?Typically running lots of wires like the stealthburner setup you linked to was only done because some people were cheap and they couldn't afford a CAN toolboard or because some people are against CAN in the klipper world.

But when you typically find, unless you're running proper cable aimed at continually being moved and conform to t he correct bend radius of stuff, one of the cables will break. You constantly hear voron users with the stock setup complaining of a cable being broken preventing something from working.So my advise would be to avoid this sort of setup, especially if you're running a mutlicore cable to the print head.

Is there any particular reason you're against using a CAN toolboard?

What type of toolhead setup is it? -

@jay_s_uk Thank you for your reply. Do I understand this correctly? As long as each fan draws less than the 2A switching load max then it doesn't matter where the +24V comes from, so I can use out1 to power the heater and the two fans.

I'm not looking to directly replicate the stealth burner setup. I like to build different toolheads for my custom built 3D printer which is why I built a tool hot swap setup. My printer is small and my duet has many available pins on it so I'd rather just use the capabilities of my mainboard then spend $45+ dollars on a Duet tool board for each new tool I build.

My idea has all of the convivences of a CAN tool board without the extra cost. My Prusa Mk4S with the Prusa Loveboard has a very similar setup to my idea for the same reasons and I wanted to implement it in the printer that I built. By making it myself it can be much more compact since it doesn't need any driver chips on it as well. Also truthfully, its a fun project for me to learn KiCAD.

-

@SamKudarauskas fair enough.

and yes, you understand that correctly -

@jay_s_uk Thank you for your help. Is the duet IO pins capable of triggering different events if it receives a pulse of being turned on/off versus a stable on or off signal?

-

@SamKudarauskas yes. have a look at M581

-

@jay_s_uk M581 appears to be used to detect going from low to high or high to low for some trigger, how can I use that to map it to different actions based off of if it goes high low high quickly or just from low to high and stays that way?

-

I'm using a Duet 3 6HC board with 3.5.4 firmware.

I have cases where I have used M581 to assign two triggers to the same input.

One for the inactive-to-active condition and the other active-to-inactive condition.

It seems to work just fine.

But I'm not sure how you would detect a steady state condition.

Frederick

-

@SamKudarauskas It might help if you explain what it is you are trying to do here. So what sensor (or other input) are you trying to monitor and what conditions do you want to detect and what do you want to do when that condition is detected.

-

@SamKudarauskas you can use M582 https://docs.duet3d.com/User_manual/Reference/Gcodes#m582-check-external-trigger to check the state of a trigger, and to trigger it if it is in a particular state.

Ian

-

@fcwilt I was curious about binding two or more macros to a single button. One to execute if the button is tapped and a different one if it is held down.

Sam

-

@SamKudarauskas said in Custom toolboard + duet wiring limitations:

@fcwilt I was curious about binding two or more macros to a single button. One to execute if the button is tapped and a different one if it is held down.

Sam

Held down how long?

You might be able to put in the trigger a G4 delay followed by a test of the appropriate input using

sensors.gpIn[#].value = 0 ; or sensors.gpIn[#].value = 1where # is the number of the gpin used as the input for the trigger to monitor.

Frederick

-

@SamKudarauskas you will need to detect it's held down in the trigger then have a while loop that looks for the release, if it's released within a certain time then carry out action A, if after that time, Action B