Updated tangle-free spool holder

-

If you ever want to know if one of your designs is really robust, leave it at a makerspace for a while.

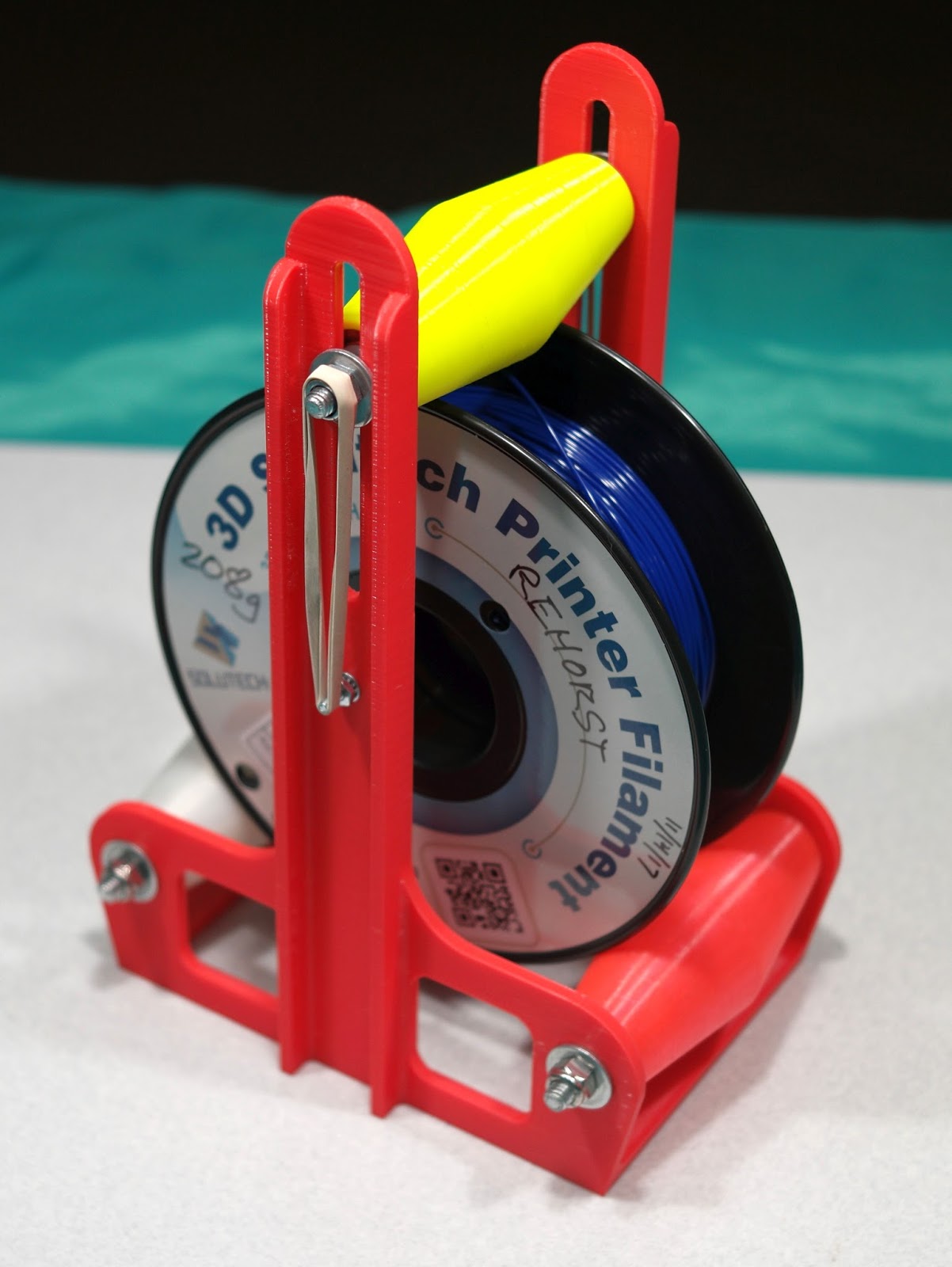

I designed and printed this spool holder a couple years ago. The top roller can slide up and down in the slots in the frame, and I just tightened the nut finger-tight to hold it in place after loading a spool. I used it at home for a few months without problems, then put it on one of the printers at the makerspace.

If you leave a bolt finger-tight at a makerspace, it will get taken apart... many, many times, no matter how many times you instruct people on the proper use. So I replaced the nut with a nylock nut and added rubber bands to pull the roller down against the spool flanges. It worked great that way, too, and no one took it apart, but the rubber bands kept disappearing.

Last week someone at the Makerspace thought it would be better without the rubber bands and suggested a modification. I agreed completely. He cut a new top roller on the lathe from some steel bar stock. Now it is heavy enough to just sit on the spool, and no rubber bands are needed.

-

For a second there I thought you might use the bar stock to "educate" people.

-

Congratulations.... nice blog

-

-

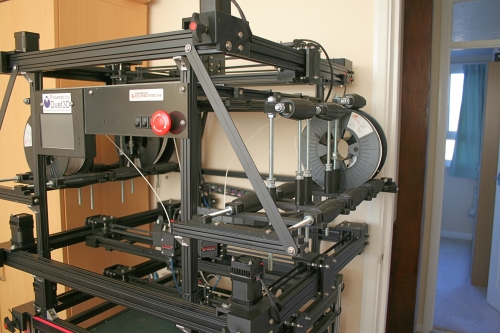

I'm a huge fan of Mark's design - the filament reels rotate rolls freely and more importantly, no more tangles. I now have 6 of them fitted to my printer.

I did my own based on Mark's design but used gravity from the outset. So instead of the slotted brackets, I used vertical hollow tubes with threaded rods fixed at right angles to the roller "axles". The weight of these rods, coupled with all the nuts and bearings is plenty to keep the upper roller in contact with the filament reel. I did a write up at the time with pictures and explanations https://somei3deas.wordpress.com/2018/06/11/5-reel-anti-tangle-filament-holder-upgrade/.

I have space under the filament holders so made the vertical side rods long enough to take those huge 2.3Kg reels as well as the "normal" 1Kg ones. But of course, when have the smaller reels fitted, the bottom of the rods hang down below the base of the holder. I've changed things around a bit so the filament reels now sit either side of the printer (3 per side) rather than being on top. I've also fitted lock nuts so that with no reel present, the rods don't hang down too far.

Kind of like this

So if you don't have access to a lathe, threaded vertical rods and printed tubes might be an alternative.

Once again, Kudos to Mark for a great idea.

-

@deckingman How many meters of 2020/2040 profile does you total machine use?

it is huge but god it is also awsome

it is huge but god it is also awsome

-

@martin1454 said in Updated tangle-free spool holder:

@deckingman How many meters of 2020/2040 profile does you total machine use?

it is huge but god it is also awsome

it is huge but god it is also awsome

Ahh, yes quite a few metres. The biggest cost of the frame isn't the extrusion, it's the Open Builds wheel kits. At the last count, with the third "load balancing" gantry added, it was about 60 sets of wheels at around £10 a pop.

That picture is the top third

- here is the whole thing

- here is the whole thing@mrehorstdmd Sorry for going off topic.

-

Cool, just a thought, for a cheaper and more accessible part, you could pause close to the end of the print and put in steel or lead shot.

-

@wyvern said in Updated tangle-free spool holder:

Cool, just a thought, for a cheaper and more accessible part, you could pause close to the end of the print and put in steel or lead shot.

I thought about doing that- just fill the printed roller up. You'd want to include resin or wax to keep the stuff from moving around, I think. Then Tom offered to turn a steel roller on the lathe so ...