Duet 2 Wifi + BL-Touch doens´t work, no Trigger-Signal

-

Yes the glue stick also helps it stick, but it keeps the plastic from bonding directly to the print surface.

-

If the bed is removable from the printer, try putting the bed+print in the fridge or freezer to help remove the print from the bed.

-

Oh, it´s this surface.. and I´m happy with this..

I playing around with diffrent surfaces at my first printer.. Aluminium+ liquid glue, or (i Don´t know the Word in english) Pertinax like elektronik boards... nothing was really good .

Also good conditions are Glass-Surface and it´s really good to remove the objects. But in 350x350x4mm, with 6 little holes.. gmm.. not easy to buy this .. and much expensive. -

@justd Try 3DLac if you can get it in your part of the world. https://www.3dlac.com/

-

Hi, yesterday arrive the new BLTouch V3.0.. and .. works super fine...

But this one, have other dimensions (Length) as the old one.Whats the best Way to calibrate the BLTouch mechanic?

-

OK.. is done.. hightmap is saved..

-

@justd said in Duet 2 Wifi + BL-Touch doens´t work, no Trigger-Signal:

Whats the best Way to calibrate the BLTouch mechanic?

https://duet3d.dozuki.com/Wiki/Test_and_calibrate_the_Z_probe

https://duet3d.dozuki.com/Wiki/Using_mesh_bed_compensation -

Now it´s working.. .. Now I tune some S3D parameters for different filaments.

Does anyone know the scripts for toolchange at printing time?

For print with 2 different Materials or different colors at one Object. I know, should be two objects in one printingfile a combined object.

What I´m searching for is, the scripts for Simplify 3 D.

Ok, it´s a little offtopic here -

You can do the tool changing either in the Duet's own tool change files (see https://duet3d.dozuki.com/Wiki/ConfiguringRepRapFirmwareCartesianPrinter#Section_Tool_change_files) or in S3D. if you put the commands ni the Duet tool change files, then all S3D needs to generate is a T command to change tool.

-

Thank you, thats wil help a lot..

But for today I see.. it´s not soo easy to change tool during printing a object.

I try it yesterday maually.. only via WEB-interface.. retract, load.. etc.. and.. I see, I must find out, how much I need to retract for a good and working toll-change. -

Whow.. These 3-Way-1Nozzle Header.. needs really 55mm for complete retract.

Puuh.. during a print for my feeling too much.I see at a manual retract and load a new filament via E2 with a ABS with lower quality.. it could be a problem to change.

After I retract te cheap ABS, I can´t load the white, better ABS.. grr..So I order a Diamond-Nozzle with 3 E3D and only 15mm retract.

I will see what happens next month.What i think about:

How is it possible, only with the stock Duet 2 Wifi, to use 3 extruders??Is that possible or do I need a expasion-Board? (it´s heavy expensive)

-

The expert on the Diamond hot end is @deckingman on this forum. See his blog at https://somei3deas.wordpress.com/tag/diamond-hot-end/.

It's easiest to drive if you add a DueX2 or DueX5 to your system, although that's not the only way.

-

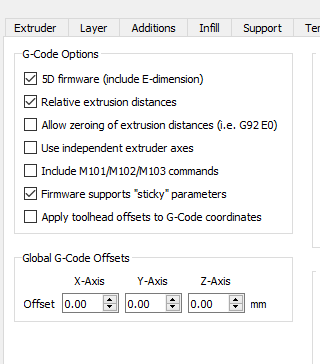

Another Question: What are the right setuo in simplify3D for the Duet 2 WiFi??

Here my setup, but I´m not shure if it is right.

What I mean is the Setup in the Process-Setupp FFF the section G-Code at the left side:

x 5D-Firmware- relative extrusion

x the G92 E0 parametre - autonomous Extruder Axis

- extensive M101/M102/M103

x Firmware support sticky parametre - use Tool-offset in G-code

Sorry I try to transplate from German.

- relative extrusion

-

@DC42.. Thanks for that hint

-

Why is it impossible in the WEB-Interface to set the Temp of tool 1 (Heater) above 270°C?

In my printfile there is the command:

M104 S280 T0

M109 S280 T0At the Config.g the maximum Temp:

M143 H1 S285 ; Set temperature limit for heater 1 to 285CIs there any configuration what I´m forgotten?

-

What strange is... with the selector I can maximum select 270.. or. better I´m able to select my own List entities of 280, but if I go to another field, there is automaticly 270 in the field what I select to 280.

But If I put in manually, then it´s possible to set it to 275 as maximum.. and the heater is heating up to 275°C.

But manually 280 switch back to 275°C.Why is that maximum fix programmed at the web-interface instead of using the config.g and the List-selctions??

-

I don't think the DWC drop down list of selectable heats is "aware" of what's set in config.g. As you discovered, you can edit the list to include whatever values you want.

What version of DWC are you using?

-

@justd said in Duet 2 Wifi + BL-Touch doens´t work, no Trigger-Signal:

Another Question: What are the right setuo in simplify3D for the Duet 2 WiFi??

Here my setup, but I´m not shure if it is right.

What I mean is the Setup in the Process-Setupp FFF the section G-Code at the left side:

x 5D-Firmware- relative extrusion

Correct.

x the G92 E0 parametre

Not needed when using relative extrusion.

- autonomous Extruder Axis

I don't know what this one means. I don't have it checked..

- extensive M101/M102/M103

RRF can use those commands to do firmware retraction, because S3D doesn't support the standard G10/G11 method. But the M101/102/103 commands are not all generated at exactly the right times. So it's better to turn this off.

x Firmware support sticky parametre

Yes.

- use Tool-offset in G-code

I have that turned off because RRF manages tool head offsets itself.

Sorry I try to transplate from German.

Kein problem!

-

@justd If you're using a M143 in config.g, make sure it's high enough.

-

Thank you for the Answers:

@Phaedrux I´m using the DWC Version 1.22.6 WiFi 1.22 FW 2.02

But I have values in the drop down List from 190 up to 285°C@dc42.. thanks help al lot.

@Stephen6309 here my M143: M143 H1 S280 ; Set temperature limit for heater 1 to 280C

Sorry, I can´t insert a pic.. only a Link to a pic.. or.. How does it here work?