First Test Print following Duet3d Upgrade

-

Let me know if these are too small, I was getting told off by the system earlier for trying to post images that were too large, so have been reducing the images by 50%

-

As I suspected, the screen shot of your machine settings extruder tab show it's using 2.85mm for your filament diameter. Change that to 1.75 or whatever the measured diameter of your filament is.

-

@Phaedrux Thanks for spotting that. I am confused about the relationship between the Wanhao profile and the Cura "Extra Fast" setting. Does that suggest that Cura uses the Wanhao profile as the base setting and then applies the Cura Extra Fast setting as a "tuning" of the model to be printed?

By the way, I'm definitely using 1.75 filament.

-

I don't think the machine setting has much of an effect on the print settings exactly. But it does define the physical properties of the machine.

Either profile you choose will likely work fine ok nice the filament diameter is set correctly.

-

@phaedrux Thanks, I will try printing the temp tower and see what happens.

-

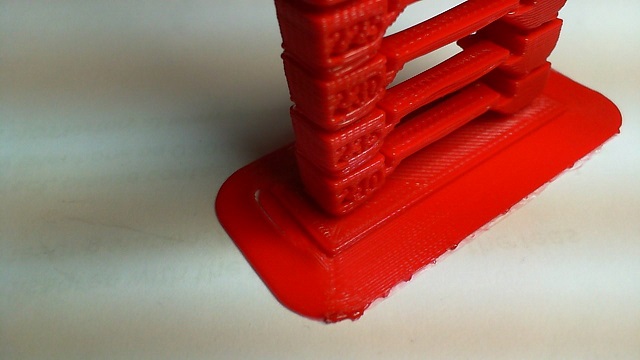

I have adjusted the machine settings to reflect 1.75 filament, re-leveled the bed, leveled the X-axis and started to print the temperature tower. Looks like a good 'squish' but there is already sign of melting on the left hand

-

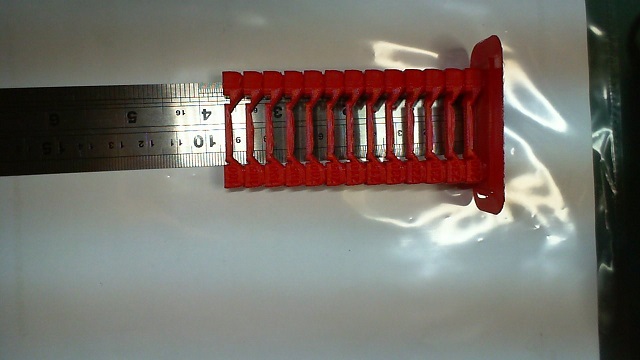

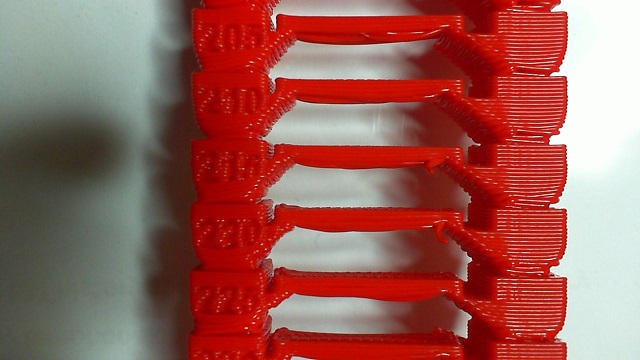

OK Folks. The temp tower has finished printing and the results are in. I am adding photos and the Cura GCode for your perusal.

-

Did you manually change the temperature? Looking at the gcode file I don't see any M104 commands in there to change the temp at the corresponding layer.

On the plus side it looks better than the Benchy.

-

I didn't change anything in the code, I just downloaded it and exported the gcode to Duet Web Control. I see the author mentioned the different temp changes and a failed Perl script.

Was I supposed to change those?

-

@phaedrux said in First Test Print following Duet3d Upgrade:

On the plus side it looks better than the Benchy.

It IS steady progress. The suggestion you made to change the M556 and M203 started it in the right direction, the correct filament size got it midway.

-

Yeah, in order to change the temperature at each layer section you need to go into the exported gcode file before printing it, find the layer height you want the temperature to change and then add your own M104 command to set the temperature. Otherwise it just prints to whole tower at the same temperature and kind of defeats the purpose.

-

I think if you can get your temperature sorted out you'll get the rest of the way there.

I'm not super familiar with the Wanhao hotend, but maybe it's a good opportunity to upgrade to an E3D V6 with proper thermistor or PT100, etc that would give you known reliable temps.

-

@phaedrux said in First Test Print following Duet3d Upgrade:

I'm not super familiar with the Wanhao hotend, but maybe it's a good opportunity to upgrade to an E3D V6 with proper thermistor or PT100, etc that would give you known reliable temps.

LOL, yep, I like your thinking, but I'm going to have to do one upgrade at a time to limit "anomalies". I have a 3mm base to add, the BLTouch and [optional] igus RJ4JP-01-08 - Solid Polymer Bearings (LM8UU) .

But I can't do any of that without getting the prints settled down.

-

This has not gone well so far.

I have no idea what point at which I should add my M104 entries on a print GCode. I found a great explanation by "inventimark" here: "3D Printing Guide #001 : Changing Temp in Gcode" https://www.youtube.com/watch?v=EATU7grYZ8E

So I fired up Repetier Host and loaded the "Better_Temperature_Tower_v5_240-180.stl" file. Next I worked through the tutorial changing the temp with the M104 command and the appropriate temp change at each new step in the tower.

I checked my X-Axis for parallel, changed my config.g to allow for the increase in extruder temp (mine had been set with the max temp well below 240) and the performed HomeAll.

I started the print.

First thing I notice is that today my Extruder temp is back to wandering. +5 Degrees above the primary temp (I set to get the extruder up to a working temp) and below by up to 2 Degrees. Strange, it wasn't doing that yesterday, though it did sort of settle down in the end.

The print starts. The skirt looks fine and sticks well, filament adhesion looks alright. I watch it until it starts the base of the first tower and then look away for a few moment. When I look back the print head is printing in midair around 10mm off the bed. I cancel the print.

Not sure if anyone can spot what I did wrong, damned if I know.

0_1559735319213_BM_Better_Temperature_Tower_v5_240-180.gcode

-

@b0m0a0k

that g code does not contain any temperature variation.Open the file in a text editor like notepad++.

then find the layer information

i.e

;LAYER:116and add the corresponding line underneath.

i.e

M104 S225 -

You're absolutely right, I posted the wrong file. Sorry. Let's try that again.

0_1559737942538_BM-EDIT_INCL_TempChanges_Better_Temperature_Tower_v5_240-180.stl

0_1559738055550_BM_Incl-Temp-Changes-Temperature_Tower_v5_240-180.gcode

-

@b0m0a0k said in First Test Print following Duet3d Upgrade:

my Extruder temp is back to wandering.

Did you save the results of the PID tune you did yesterday? After the tune, send M500 to save it. You'll then need M501 at the end of your config.g to load those tuned values again at boot up.

@b0m0a0k said in First Test Print following Duet3d Upgrade:

When I look back the print head is printing in midair around 10mm off the bed.

It kind of sounds like the heater either got turned off. Did you happen to notice what the temperature was or what the temp graph looked like?

@b0m0a0k said in First Test Print following Duet3d Upgrade:

You're absolutely right, I posted the wrong file. Sorry. Let's try that again.

0_1559737942538_BM-EDIT_INCL_TempChanges_Better_Temperature_Tower_v5_240-180.stl

0_1559738055550_BM_Incl-Temp-Changes-Temperature_Tower_v5_240-180.gcode

That Gcode file has M104 commands in it at least. Try removing the P0 from the command. Instead of M104 P0 S235, try just M104 S235. Also it looks like one or more temperature steps got skipped/duplicated. But you're on the right track.

-

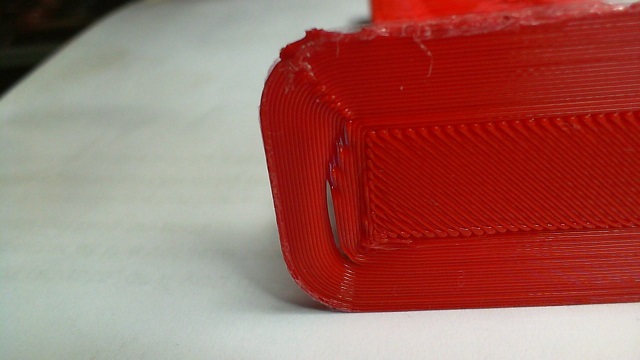

I can see 2 problems here:

- Layer height is 0.3 I would go for 0.2 its more "standard" height and will let you compare your print with others.

- looks like there is over extrusion, try lowering your flow rate

-

Under extrusion:

Over extrusion:

-

@phaedrux I did not set M501 at the end of config.g. I have now.

I have just re-run the PID tuning on both the heated bed and the extruder. The bed had not changed a whole lot from yesterday. I re-ran the Extruder PID auto-tune 4 times and it changed every time (I still don't understand why it doesn't appear to cycle the 8 times I ask for in in the auto-tune instruction).

When retesting the Extruder temp is still going over by 5-6 Degrees.

I'm going to plug in the last set of results to config. and look at @dc advice on fine tuning;

Quote;

"If the temperature oscillates around the target value, increase the dead time (D) parameter. It it's slow to respond to changes in the environment (e.g. the print cooling fan turning on), you can try reducing the D parameter.If the temperature overshoots, increase the gain (A parameter). If it undershoots, reduce the A parameter."

These are my latest Heater settings;

; Heaters

; Bed [H0 - Heater 0]

M143 H0 S70 ; Set temperature limit for heater 0 to 70C

M305 P0 T100000 B3988 R4700 ; Set thermistor + ADC parameters for heater 0

M307 H0 A114.0 C410.3 D2.7 S1.0 V12.3 B0 ; PID Auto-tune Values for Bed [H0]; Extruder [H1 - Heater 1]

M143 H1 S245 ; Set temperature limit for heater 1 to 245C

M305 P1 T100000 B3988 R4700 ; Set thermistor + ADC parameters for heater 1

M307 H1 A376.3 C154.7 D9.4 S1.0 V12.4 B0 ; PID auto-tune Values for Extruder [H1]