First Test Print following Duet3d Upgrade

-

@veti Haven't tried that yet, great suggestion. I'm desperately trying to get this to an acceptable level where I can print the BLTouch mount and get that installed to help with the hell that is bed levelling

-

Are you using the stock extruder? I just configured a model like this for someone and the extruder steps/mm were in the 90s (like 94).

Were you serious with the be leveling comment? Why is bed leveling so difficult for you?

Can you post the full config.g file.

-

It certainly seems like under extrusion in some of the pictures.

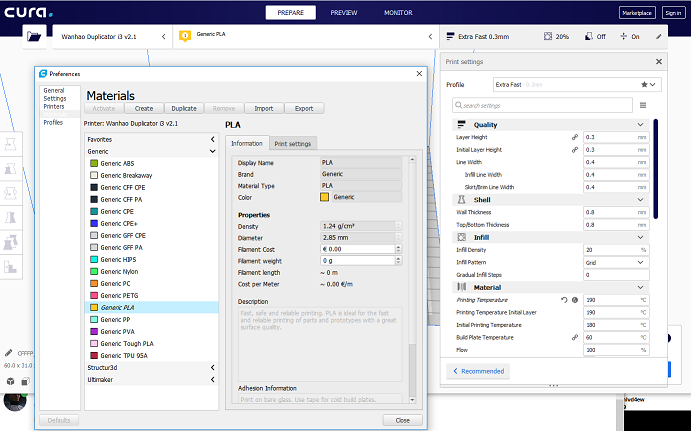

Can you check your printer setup in Cura to ensure that it's set to use 1.75mm filament and not 2.85mm.

Also the temperature tower would be a good idea. We need to verify that your temperatures are accurate, or at least find a temperature where extrusion can happen smoothly.

-

@veti said in First Test Print following Duet3d Upgrade:

can you print a temperature tower?

https://www.thingiverse.com/thing:2625999I agree, it looks to me that your test print with the Duet is printed at too high a temperature.

-

@bricor Yes, I am using the stock Wanhao Duplicator i3 v2.1 extruder wich is described as;

MK10 Single-Extruder (with Steel X-Carriage)

Re: Bed leveling. Yeah, kinda am. Its just such and ambiguous process. You can give 4 people the same printer and tell them what to do and they will all assume a different criteria for success. How on earth are you supposed to condense that into anything approaching a fool-proof method.

-

Apologies for going off subject with the bed leveling, but it may be the i3 design that's the issue. Bed leveling is a straight forward procedure on a printer like this and does not require a probe. Delta printers require a bit more to get right and probing makes life easier but also not necessary.

To get back on track, print the temp tower and post the results. Interested to see where this goes.

-

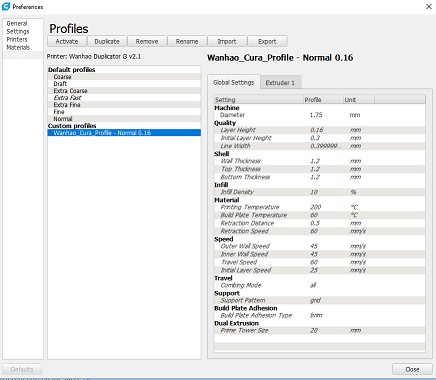

I have the print running at what Cura (4.1.0) calls "Extra Fast" the settings for which are as follows;

Resolution: 0.3mm

Print Temp: 190

Print Temp Initial Layer: 190

Initial print temp: 180

Build Plate Temp: 60

Flow: 100%

Retraction enabled

Retraction Distance: 6.5mm

Retraction Speed: 25

Print Speed: 60

Travel Speed: 120

Initial Layer Speed: 30.0

Cooling Enabled

FAN Speed: 100

FAN Regular Speed: 100

FAN Max Speed: 100

Support: No

Build Plate Adhesion: Brim

Brim Width: 8.0

Print Sequence: All At OnceHowever. The Wanhao Duplicator i3 profile is active in the Cura interface so I'm not sure how much of that it keeps if you choose a Cura based resolution rather than the Wanhao profile (included below).

It's worth mentioning that I used the "Extra Fast" setting to produce the better quality Benchy while the Wanhao i3 was still using the factory Melzi board.

-

Let me know if these are too small, I was getting told off by the system earlier for trying to post images that were too large, so have been reducing the images by 50%

-

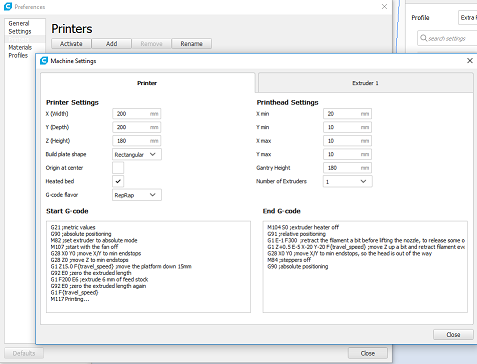

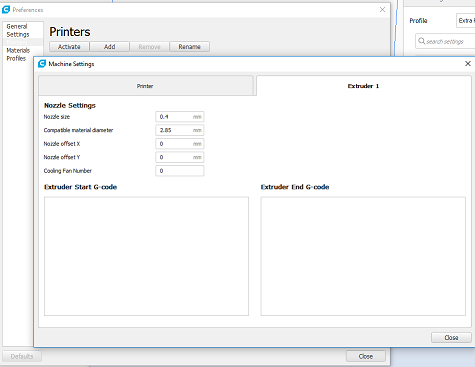

As I suspected, the screen shot of your machine settings extruder tab show it's using 2.85mm for your filament diameter. Change that to 1.75 or whatever the measured diameter of your filament is.

-

@Phaedrux Thanks for spotting that. I am confused about the relationship between the Wanhao profile and the Cura "Extra Fast" setting. Does that suggest that Cura uses the Wanhao profile as the base setting and then applies the Cura Extra Fast setting as a "tuning" of the model to be printed?

By the way, I'm definitely using 1.75 filament.

-

I don't think the machine setting has much of an effect on the print settings exactly. But it does define the physical properties of the machine.

Either profile you choose will likely work fine ok nice the filament diameter is set correctly.

-

@phaedrux Thanks, I will try printing the temp tower and see what happens.

-

I have adjusted the machine settings to reflect 1.75 filament, re-leveled the bed, leveled the X-axis and started to print the temperature tower. Looks like a good 'squish' but there is already sign of melting on the left hand

-

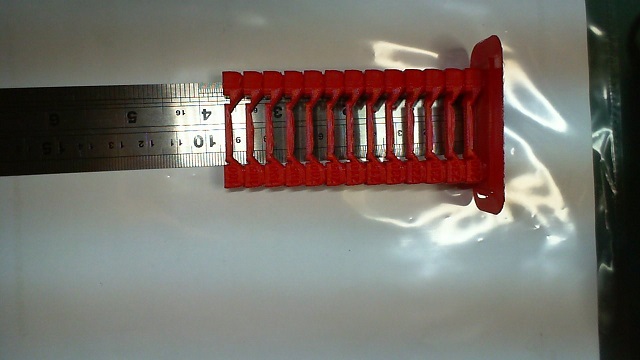

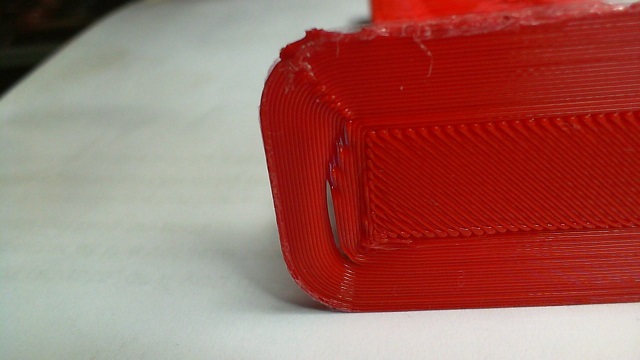

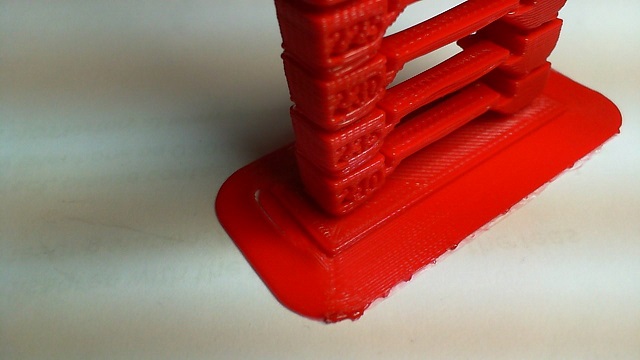

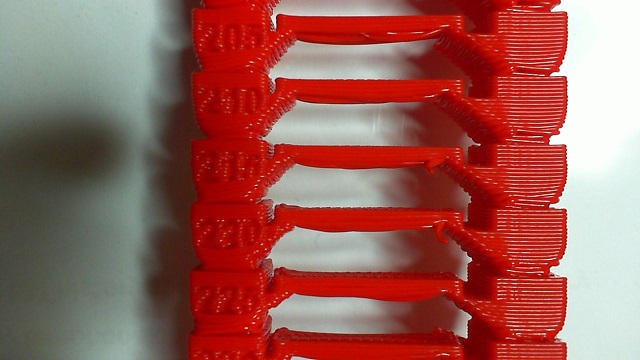

OK Folks. The temp tower has finished printing and the results are in. I am adding photos and the Cura GCode for your perusal.

-

Did you manually change the temperature? Looking at the gcode file I don't see any M104 commands in there to change the temp at the corresponding layer.

On the plus side it looks better than the Benchy.

-

I didn't change anything in the code, I just downloaded it and exported the gcode to Duet Web Control. I see the author mentioned the different temp changes and a failed Perl script.

Was I supposed to change those?

-

@phaedrux said in First Test Print following Duet3d Upgrade:

On the plus side it looks better than the Benchy.

It IS steady progress. The suggestion you made to change the M556 and M203 started it in the right direction, the correct filament size got it midway.

-

Yeah, in order to change the temperature at each layer section you need to go into the exported gcode file before printing it, find the layer height you want the temperature to change and then add your own M104 command to set the temperature. Otherwise it just prints to whole tower at the same temperature and kind of defeats the purpose.

-

I think if you can get your temperature sorted out you'll get the rest of the way there.

I'm not super familiar with the Wanhao hotend, but maybe it's a good opportunity to upgrade to an E3D V6 with proper thermistor or PT100, etc that would give you known reliable temps.

-

@phaedrux said in First Test Print following Duet3d Upgrade:

I'm not super familiar with the Wanhao hotend, but maybe it's a good opportunity to upgrade to an E3D V6 with proper thermistor or PT100, etc that would give you known reliable temps.

LOL, yep, I like your thinking, but I'm going to have to do one upgrade at a time to limit "anomalies". I have a 3mm base to add, the BLTouch and [optional] igus RJ4JP-01-08 - Solid Polymer Bearings (LM8UU) .

But I can't do any of that without getting the prints settled down.