Core XY weired behavior of the Z-Axis and Endstop config

-

Hello,

i just wired up my new Core XY machine. First i cnofigured the Endstops at the X and Y axis and everythink just went fine. Then i tried to configure also the Z-axis and i coudn't get it right. L

Please take a look at the Config.g file at the bottom.

So my endstop position at the Z-axis is at the botom of the machine. So when i Home the Z-axis, it move into the right direction (down) where the endstop is located. Then it hits the Endstop and at the Duet Web Interace, it shows the value 300 at the actual Z posiotion.So now i klicked on the -5mm incremental button at the Z-axis doesnt move. It's strange because for my understanding it should only be able to move in the Z minus direction. If i klick on the Z +5mm the axis moves up to Z=0mm then i klicked again on the Z+5mm and the Z-axis moved down again.

I tried every possible combination at the M208 and M574 commands and i could not find out why the axis behaves like that.

Please give me a guess if you have any idea what i could change.

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Thu Jul 18 2019 11:42:53 GMT+0200 (Mitteleuropäische Sommerzeit); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder movesM667 S1 ; Select CoreXY mode

; Network

M550 P"CoreXY" ; Set machine name

M552 P192.168.137.18 S1 ; Enable network and acquire dynamic address via DHCP

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S1 ; Physical drive 0 goes forwards

M569 P1 S1 ; Physical drive 1 goes forwards

M569 P2 S0 ; Physical drive 2 goes forwards

M569 P3 S1 ; Physical drive 3 goes forwards

M569 P4 S1 ; Physical drive 4 goes forwards

M569 P5 S1 ; Physical drive 5 goes forwards

M569 P6 S1 ; Physical drive 6 goes forwards

M350 X16 Y16 Z16 E16:16:16:16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z650.00 E420.00:420.00:420.00:420.00 ; Set steps per mm

M566 X900.00 Y900.00 Z12.00 E120.00:120.00:120.00:120.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z800.00 E1200.00:1200.00:1200.00:1200.00 ; Set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00:250.00:250.00:250.00 ; Set accelerations (mm/s^2)

M906 X800.00 Y800.00 Z800.00 E800.00:800.00:800.00:800.00 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X425 Y343 Z0 S0 ; Set axis maxima

M208 X0 Y0 Z300 S1 ; Set axis minima; Endstops

M574 X1 Y1 Z2 S0 ; Set active high endstops; Z-Probe

M558 P5 H5 F120 T6000 ; Set Z probe type to switch and the dive height + speeds

G31 P500 X0 Y0 Z2.5 ; Set Z probe trigger value, offset and trigger height

M556 S50 X0 Y0 Z0 ; Set orthogonal axis compensation parameters

M557 X15:215 Y15:195 S20 ; Define mesh grid; Heaters

M307 H0 B0 S1.00 ; Disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

M305 P1 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S280 ; Set temperature limit for heater 1 to 280C

M305 P2 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 2

M143 H2 S280 ; Set temperature limit for heater 2 to 280C

M305 P3 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 3

M143 H3 S280 ; Set temperature limit for heater 3 to 280C

M305 P4 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 4

M143 H4 S280 ; Set temperature limit for heater 4 to 280C; Fans

M106 P0 S0 I0 F500 H T45 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic power saving

;M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss; Custom settings are not configured

; Miscellaneous

T0 ; Select first toolThnaks

-

try the console and see any reported error message.

ie. put in G0 Z295

-

I put in the G-code "G0 Z295" in the console and nothing hapend. No error Messages only "G0 Z295" cloered in Green.

Also weired, if i send "G1 X20 Y20 F2000" the X-axis and Y-axis move, but if they are positioned the Z-axis moves also.

-

@philipp-r said in Core XY weired behavior of the Z-Axis and Endstop config:

, but if they are positioned the Z-axis moves also.

what do you mean by positioned?

your M92 has Z650.00. this is a unusual number.

what lead screw do you have? -

Where is your M584 drive mapping line ?

https://duet3d.dozuki.com/Wiki/Gcode#Section_M584_Set_drive_mapping -

the M584 is not required if the default mapping is used.

-

@veti said in Core XY weired behavior of the Z-Axis and Endstop config:

the M584 is not required if the default mapping is used.

Ah, thank you for this information

-

I use a precision Ballscrew with a 5mm pitch without a gear.

-

@veti i ment, when i send the G-code "G1 X20 Y20 F2000" the X and Y-axis move to the position X20 Y20... after they reached this position the Z-axis will also begin to move without any commend used.

-

@philipp-r

that is very strange behavior. in which direction does it move? how far does it move?

do you have a config-overwrite file?how many motors does your z axis have. how are they connected to the duet?

-

@philipp-r said in Core XY weired behavior of the Z-Axis and Endstop config:

I put in the G-code "G0 Z295" in the console and nothing hapend. No error Messages only "G0 Z295" cloered in Green.

Also weired, if i send "G1 X20 Y20 F2000" the X-axis and Y-axis move, but if they are positioned the Z-axis moves also.

The lack of Z axis movement can be explained by the fact that you have set the maximum limit to 0 and the minimum limit to 300.

"M208 X425 Y343 Z0 S0 ; Set axis maxima

M208 X0 Y0 Z300 S1 ; Set axis minima"Change that to be:

M208 X425 Y343 Z300 S0 ; Set axis maxima

M208 X0 Y0 Z0 S1 ; Set axis minimaYou have defined the Z axis end stop to be at the high end (Z max)

M574 X1 Y1 Z2 S0

Is that intentional? Do you really have that end stop at Z max?

-

@deckingman said in Core XY weired behavior of the Z-Axis and Endstop config:

The lack of Z axis movement can be explained by the fact that you have set the maximum limit to 0 and the minimum limit to 300.

good catch. but why would that cause z movement after x and y movement?

-

@veti said in Core XY weired behavior of the Z-Axis and Endstop config:

@deckingman said in Core XY weired behavior of the Z-Axis and Endstop config:

The lack of Z axis movement can be explained by the fact that you have set the maximum limit to 0 and the minimum limit to 300.

good catch. but why would that cause z movement after x and y movement?

I didn't say it would - I was very careful in my choice of words

I suspect that Z movement may be something else, but the OP should at least put the axis limits right first.

-

@deckingman thanks for your answer.

Your right i changed it and the lack is gone.

Yes i did thet intentionaly, because the endstop is at the lowest position the bed can reach. Related to the printhead this is the max Position. I also chose the right hand rule for thze coordinate frame.

I want to tell the machine if the Z-axis hits the endstop, it is position 300mm. But however i change the M208 command i did not get the right position.

When i home the Z-axis and type in 300mm into the Machine setting/Headposition at the left corner at the Web interface, the machine behaves like i want it to.

Does anybody know if i can save this kind of input or which M-command i should use to get the same Result. -

-

list itemit will move downwards until it hits the endstop again.

-

no i don't have an config-overwrite file

-

i use only one motor and its puged in at the Z-axis spot on the duet2ethernet

-

-

i would suggest you start without the z max for now and try and get the machine working.

use the probe for now to determine z=0.

determining z=0 from a z max endstop is not that easy.

-

Do you have the direction of your Z motor correct? If the bed moves in the Z direction (not the print head), then increasing Z should move the bed down. The Z coordinate is the distance between the print head reference point and the bed.

-

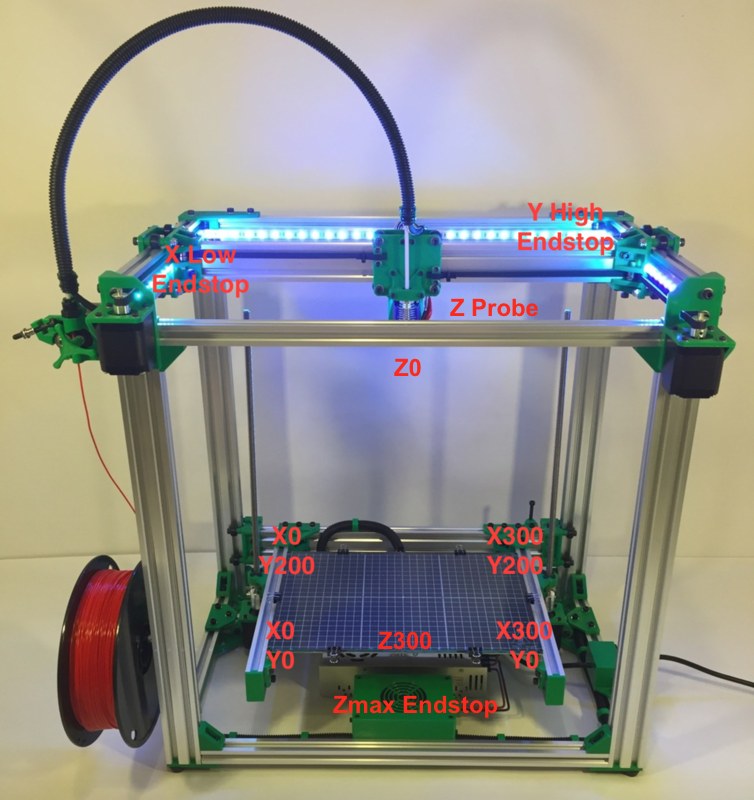

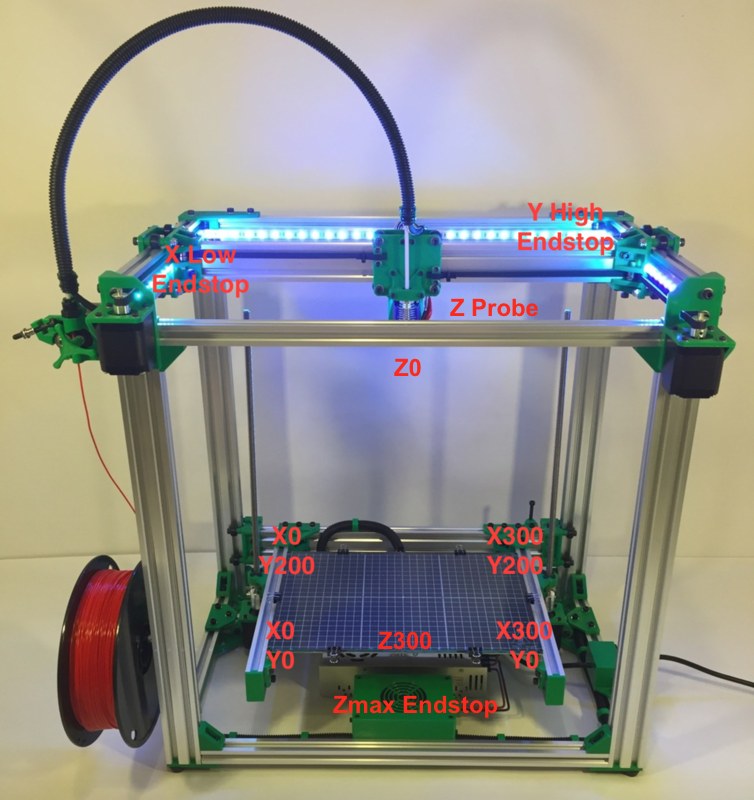

dbot axis.png

dbot axis.pngDoes this make more sense?

-

@dc42 yes when i increase the Z value the bed moves down. I checked the direction of all axis they are correct.

is there a change that there is something wrong with the board?

-

@phaedrux said in Core XY weired behavior of the Z-Axis and Endstop config:

dbot axis.png

dbot axis.pngDoes this make more sense?

Thank you for the picture. This is exactly like i set up the Z-axis.