ferruled connectors

-

Hello

Thanks for the answers but I believe I did not make myself very well understood.

The ferrule connectors that I am talking about are already crimped to the wires, from the factory.

I was talking about tightening the ferrule connectors into the Duet3D board terminal blocks.

The out-of-the-box ferrule connector is a hollow tube. One end of this tube is factory-crimped to the wire, and the other end of this tube is free and goes into Duet's terminal blocks.

Do I tighten this free end of the tube in the Duet board's terminal block until the tube gets mechanically deformed ? Or do I do the flattening myself (e.g., using pliers) until the connector gets shaped as a flat rectangle, and put that flattened end of the connector in Duet's terminal blocks and then tighten those screws ?

Which way is best ? In time, which of these variants is the most reliable (i.e., does not need to be pereiodically verified and tightened again)

Thanks and regards

-

@mihaitintea said in ferruled connectors:

Do I tighten this free end of the tube in the Duet board's terminal block until the tube gets mechanically deformed ?

Yes, after crimping the ferrule onto the wire it will have one of several shapes; this goes straight into the terminal block and you tighten down the screw in the terminal according to the torque for the terminal. If that results in the ferrule further deforming then thats ok.

-

@mihaitintea said in ferruled connectors:

The out-of-the-box ferrule connector is a hollow tube. One end of this tube is factory-crimped to the wire, and the other end of this tube is free and goes into Duet's terminal blocks.

Do I tighten this free end of the tube in the Duet board's terminal block until the tube gets mechanically deformed ? Or do I do the flattening myself (e.g., using pliers) until the connector gets shaped as a flat rectangle, and put that flattened end of the connector in Duet's terminal blocks and then tighten those screws ?

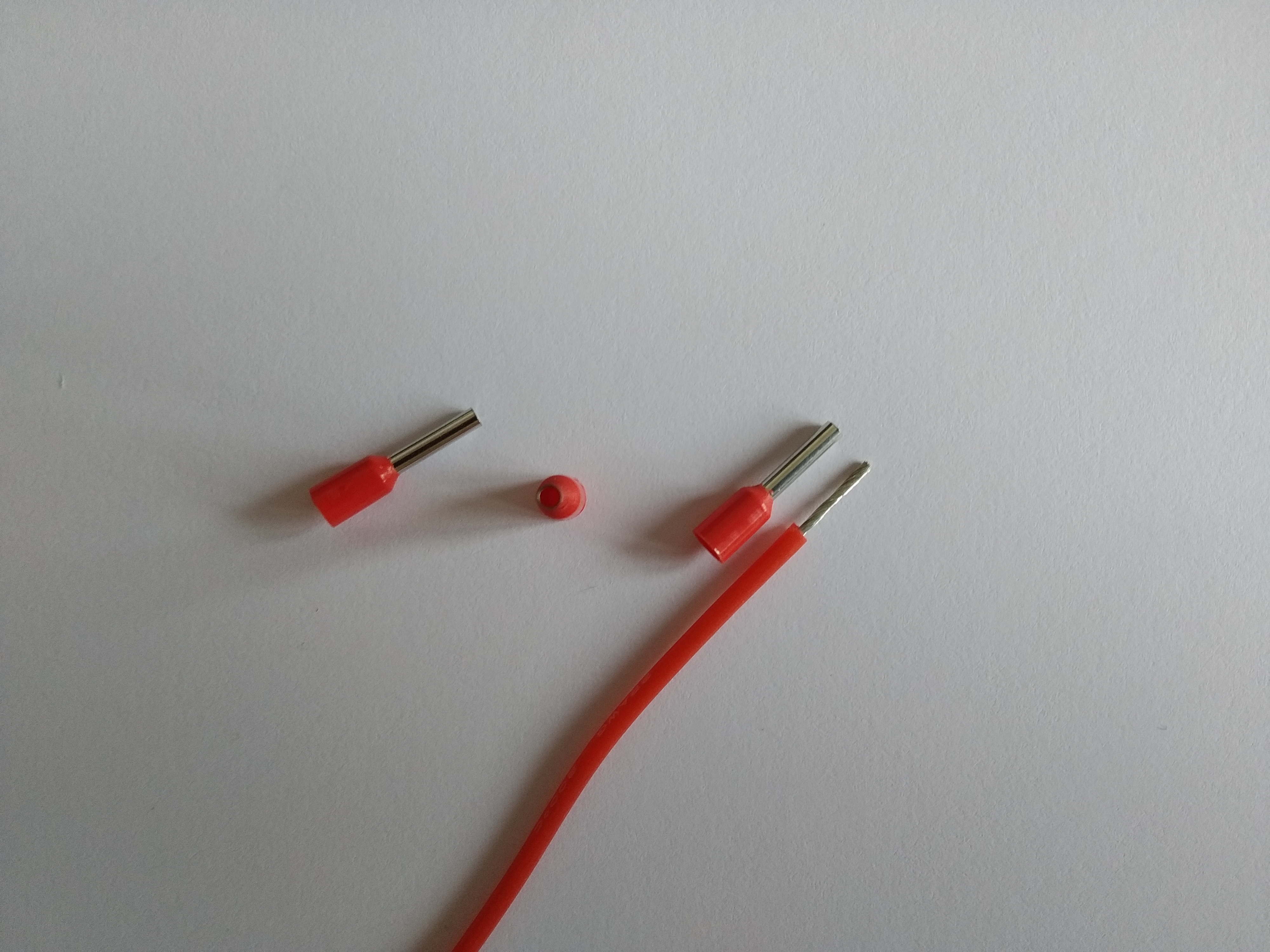

Here's the kind of ferrule that you should be using:

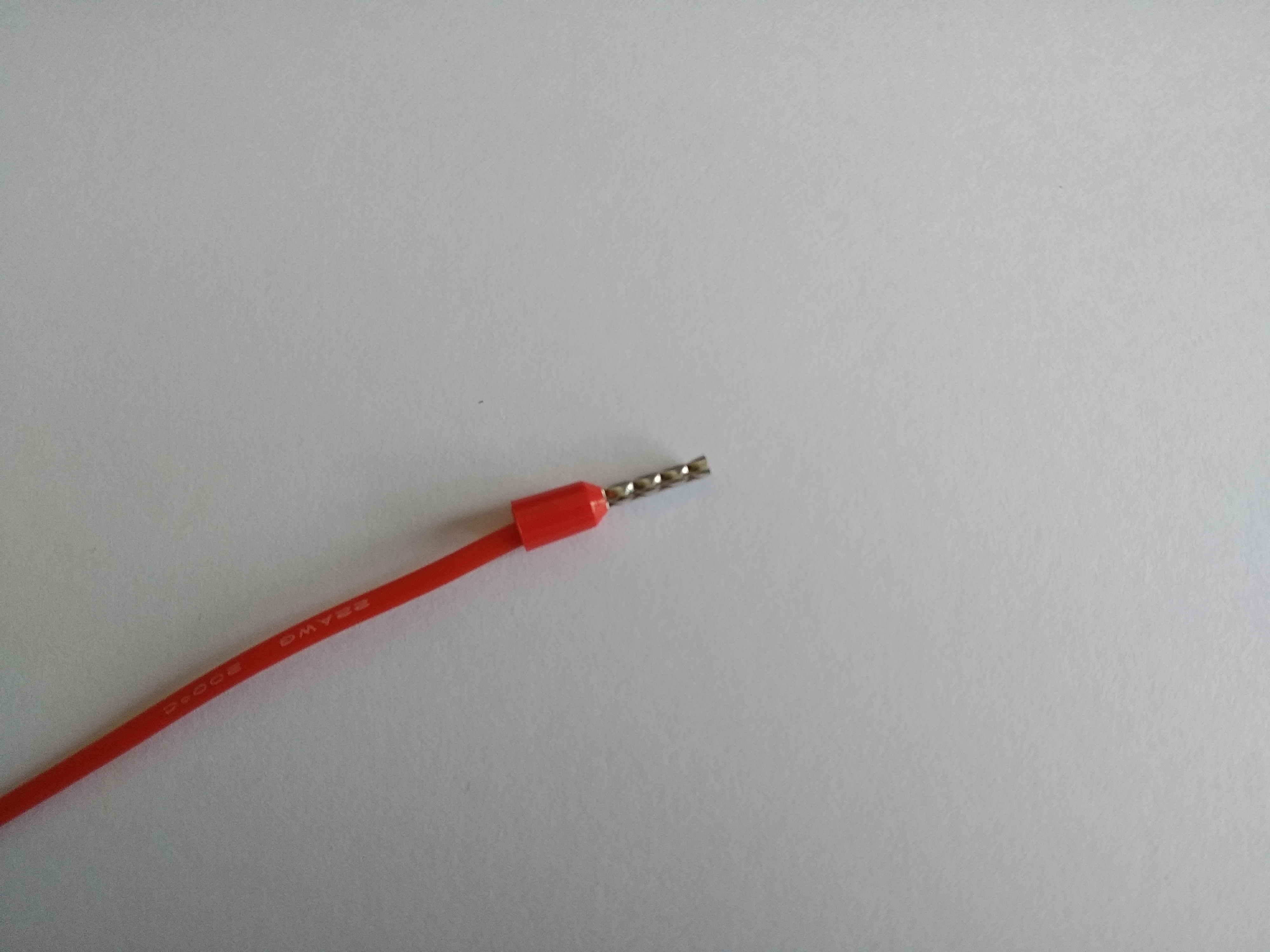

One end is insulated to prevent any chance of a short. The wire is then stripped so that the wire is the same length as the exposed metal part of the ferrule. The wire is inserted into the ferrule and crimped.

If the manufacturer didn't strip the wire long enough, so that metal tube is not filled all the way to the end with wire, simply cut the end of the ferrule off with some side cutters so that you can see the crimped wire at the end of the metal tube.

Then insert the ferrule into the connector and tighten down the retaining screw while supporting the connector against the force of tightening the screw down.

-

Dear Sir,

Thank you so much for the detailed explanation. That kind of knowledge is either gathered from advice as you provided (truly kindly and for free), or hard-learned through -- hopefully not ! -- unfortunate experiences. Fire risk is something that should be taken seriously and thoroughly adviced by whoever is selling whatever may expose buyers to it -- including Amp-consuming devices such as 3D printers.

Many thanks and wish you the best.

Truly yours

Mihai -

@bearer said in ferruled connectors:

Risky business specifying size according to colour...

I use the smallest ferrule that fits the wire.

-

@zapta said in ferruled connectors:

I use the smallest ferrule that fits the wire.

That works, but if it happens to be orange, telling others to go buy orange ones isn't a failsafe method was the point I was trying to make. While there are a few standards or conventions, its not a single global standard.

-

@bearer, that's correct. Sometimes even the same kit has different sizes for the same color