Prusa upgraded to duet, weird extrusion

-

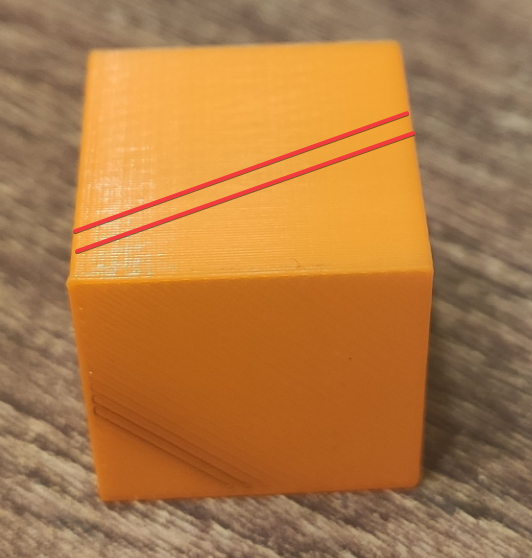

Yes i can see in the first pic that the angle is different.

So its 99% extruder related.

Have you checked for any debris in the meshing gears? Especially when you grease them stuff can stick to it.

Can you also uninstall the stepper, turn it by hand and feel any crunchyness? What do you feel in comparison when you turn the 1.8 degree stepper? the 0.9 should feel substantially smoother -

@NitroFreak said in Prusa upgraded to duet, weird extrusion:

Yes i can see in the first pic that the angle is different.

So its 99% extruder related.

Have you checked for any debris in the meshing gears? Especially when you grease them stuff can stick to it.

Can you also uninstall the stepper, turn it by hand and feel any crunchyness? What do you feel in comparison when you turn the 1.8 degree stepper? the 0.9 should feel substantially smootherThe gears are clean, the motor feels insanely smooth and non crunchy.. The old one feels much harder to turn by hand, at least twice.

I am running out of ideas.

-

Another interesting observation: my bed is making a clicking noise..??

It's a brand new 12V MK52 magnetic heatbed for prusa MK2.5. The PSU is not clicking, DUET isn't too. The clicking originates somewhere around the middle of the heated bed and is in sync with the power LED. What? Is this even fine? Some reddit posts say this is normal for a prusa, but I haven't ever heard this sound during three years of owning one.

It is also VERY well timed with the pulses I get from the motor.

https://www.youtube.com/watch?v=0nk4qrPI_9I

(Increase the volume) -

-

@jay_s_uk said in Prusa upgraded to duet, weird extrusion:

@Murloc992

It's a known issue

https://blog.prusaprinters.org/dev-diary-2-how-we-made-the-heatbed-silent/It seems.. Maybe MK2.5 didn't have this.

Anyways, changed X belt to the one I found lying around, will see if this changes anything from the steel mesh belts.

-

I dont think its the belts as otherwise the artifacts would be vertical and not on an angle, and definitely not changing with the size of the cube.

-

steel belts and 16 tooth pulleys that do a 180 degree directional change do not play well together.

if not now it will prevent headache in the future. -

@NitroFreak said in Prusa upgraded to duet, weird extrusion:

I dont think its the belts as otherwise the artifacts would be vertical and not on an angle, and definitely not changing with the size of the cube...

Did you go through the prusa thread about the 0.9 degree steppers yet?Not yet, it's a large post. I hope to do it today maybe.

Just not sure what else to try at the moment. I could try using a bearing idler to be honest, just to see if I get some kind of wobble from the idling and the noise is just a placebo kind of thing.

-

Looking back, are your e steps per mm 276 still? I think they should be around 410 for BMG with 1.8 degree motors, and higher for 0.9. This might mean the filament isn’t running in the hobbed part of the gear. This would force the two hobbed shafts further apart, far enough for the gears on the shafts to mesh poorly, and give poor extrusion. Is there any chance you’ve assembled the extruder incorrectly? Feel free to post pictures!

Swapping out the extruder drive for your old one might also me an option, if it fits the Bear setup.

Ian

-

@droftarts said in Prusa upgraded to duet, weird extrusion:

Looking back, are your e steps per mm 276 still? I think they should be around 410 for BMG with 1.8 degree motors,

its a prusa. so no 3:1 reduction. thats just the normal around 100 something increased by the 0.9 stepper.

-

@Veti Ah yes, of course. Might still be strange meshing of the two filament drive gears, though.

Ian

-

@Veti said in Prusa upgraded to duet, weird extrusion:

@droftarts said in Prusa upgraded to duet, weird extrusion:

Looking back, are your e steps per mm 276 still? I think they should be around 410 for BMG with 1.8 degree motors,its a prusa. so no 3:1 reduction. thats just the normal around 100 something increased by the 0.9 stepper.

If to be completely accurate: 133 default, 138 after calibration with 1.8' motor. 276 with 0.9' motor. Steps are spot on.

@droftarts said in Prusa upgraded to duet, weird extrusion:

Is there any chance you’ve assembled the extruder incorrectly? Feel free to post pictures!

Not a chance. I've owned this printer for several(3+) years by now. Went through MK2.5S, MK2.5X(custom), MK3 "hybrid"(adapted for 2.5), bear extruder. Never assembled it wrong.

Here's how my filament is going through the main bondtech gear:

@droftarts said in Prusa upgraded to duet, weird extrusion:

@Veti Ah yes, of course. Might still be strange meshing of the two filament drive gears, though.

Ian

Meshing seems fine, but I will try putting in 623 bearing idler after I customize it.

-

I know what it might be. In the Prusa bear thread they talked about how the 0.9 might not have enough torque to direct drive the extruder.

I just read that you‘re using the 12v PS.

0.9 degree steppers really want 24v otherwise you will not be able to reach good speeds and torque, because you literally only have half the torque vs 24v and torque is further halved because you have the 0.9 instead of a 1.8 stepper. I could imagine the extruder is lacking until it reaches the next full step where it snaps to, resulting in this sort of extrusion inconsistency.I would suggest you try a 24v power supply

-

@NitroFreak said in Prusa upgraded to duet, weird extrusion:

I know what it might be. In the Prusa bear thread they talked about how the 0.9 might not have enough torque to direct drive the extruder.

I just read that you‘re using the 12v PS.

0.9 degree steppers really want 24v otherwise you will not be able to reach good speeds and torque, because you literally only have half the torque vs 24v and torque is further halved because you have the 0.9 instead of a 1.8 stepper. I could imagine the extruder is lacking until it reaches the next full step where it snaps to, resulting in this sort of extrusion inconsistency.I would suggest you try a 24v power supply

I actually once pushed filament out at 60mm/s, 100mm of it. Nothing skipped. The speed of the extruder wheel spooked me quite a lot though.

Yeah, sounds good, but I have 12V bed, 12V heater, 12V fans, etc..

-

did you try the original 1.8 stepper again? you initially wanted to get rid of the vfa, which only need the swap of the x and y stepper.

-

@Murloc992 said in Prusa upgraded to duet, weird extrusion:

@NitroFreak said in Prusa upgraded to duet, weird extrusion:

I know what it might be. In the Prusa bear thread they talked about how the 0.9 might not have enough torque to direct drive the extruder.

I just read that you‘re using the 12v PS.

0.9 degree steppers really want 24v otherwise you will not be able to reach good speeds and torque, because you literally only have half the torque vs 24v and torque is further halved because you have the 0.9 instead of a 1.8 stepper. I could imagine the extruder is lacking until it reaches the next full step where it snaps to, resulting in this sort of extrusion inconsistency.I would suggest you try a 24v power supply

I actually once pushed filament out at 60mm/s, 100mm of it. Nothing skipped. The speed of the extruder wheel spooked me quite a lot though.

Yeah, sounds good, but I have 12V bed, 12V heater, 12V fans, etc..

i doubt it was pushed out at 60mm/s , even my volcano with a BMG grinds filament after 12mm/s filament speed. Maybe you mean print speed? or mm/min?

If you do not want to convert to 24v, i suggest your best bet would be to put the 1.8 degree stepper back in or use a 3:1 gearing -

Fair enough re assembly, just running out of ideas! @NitroFreak isn’t quite right about torque of 0.9 motors (see https://duet3d.dozuki.com/Wiki/Choosing_and_connecting_stepper_motors#Section_Step_angle ) except at high speed, but the extruder doesn’t turn that fast. Powering with 24V would be a better option for 0.9 degree motors, though.

Ian

-

@NitroFreak said in Prusa upgraded to duet, weird extrusion:

@Murloc992 said in Prusa upgraded to duet, weird extrusion:

@NitroFreak said in Prusa upgraded to duet, weird extrusion:

I know what it might be. In the Prusa bear thread they talked about how the 0.9 might not have enough torque to direct drive the extruder.

I just read that you‘re using the 12v PS.

0.9 degree steppers really want 24v otherwise you will not be able to reach good speeds and torque, because you literally only have half the torque vs 24v and torque is further halved because you have the 0.9 instead of a 1.8 stepper. I could imagine the extruder is lacking until it reaches the next full step where it snaps to, resulting in this sort of extrusion inconsistency.I would suggest you try a 24v power supply

I actually once pushed filament out at 60mm/s, 100mm of it. Nothing skipped. The speed of the extruder wheel spooked me quite a lot though.

Yeah, sounds good, but I have 12V bed, 12V heater, 12V fans, etc..

i doubt it was pushed out at 60mm/s , even my volcano with a BMG grinds filament after 12mm/s filament speed. Maybe you mean print speed? or mm/min?

If you do not want to convert to 24v, i suggest your best bet would be to put the 1.8 degree stepper back in or use a 3:1 gearingMaybe the motor skipped and I didn't hear it? I can try putting the original motor back in, but it also was pulsing, just less.

Like that:

-

How about the other way around; maybe you have the idler overtightened and the BMG gears are meshing badly because they’re too tight?!

Ian

-

@droftarts said in Prusa upgraded to duet, weird extrusion:

How about the other way around; maybe you have the idler overtightened and the BMG gears are meshing badly because they’re too tight?!

Ian

I have tried the "correct tension" method: so that it just grabs with minimal tension and ofc overtightening, no difference. BUT I have an idea. Let me check.