Duet 3 3 z motors config

-

Help needed.

I am trying to set up a core xy with 3 z motors. And I think I have sent myself insane trying to set it up. Not much point posting my config files as I have edited it so many times, I go cross eyed trying to figure out what I have done. But nothing has worked so far.

So if any of you kind people could share your config etc files, so I could compare to what I have, I would really appreciate it.

TIA

Matthew

-

@mattbaker Are you using a Duet 3 6HC with 3HC expansion board? What seems to be the problem?

Ian

-

@mattbaker said in Duet 3 3 z motors config:

I am trying to set up a core xy with 3 z motors.

normally you do not need to do more than add the extra motors to the M584 line like

M584 X0 Y1 Z2:4:5 E3current acceleration etc. is the same for all z motors

see this article for more information and extra stuff

https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors -

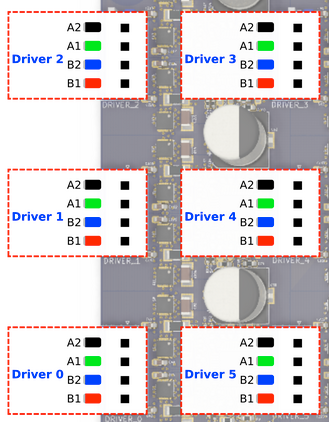

@mattbaker One of the gotchas on Duet 3 wiring is that the motor driver layout:

2 3

1 4

0 5not

2 5

1 4

0 3See:

Make sure the motors are plugged into the right headers!Ian

-

Ive wired the steppers correctly, found that one out the hard way.

I'm trying to get the 3 axis levelling working.

-

@droftarts I'm trying to get the 3. axis levelling working. I'm using the Duet 3 6HC. without the expansion board at present.

-

@mattbaker Okay. See the link @Veti posted earlier. You need the following for bed levelling with 3 independent Z motors:

- to know which motor driver links to which leadscrew, eg Z2 is front left, Z3 is back centre, Z4 is front right

- Leadscrew position defined by M671, in the order the leadscrews are defined by M584!

- Change bed.g to probe as near as possible to each leadscrew

For details, see https://duet3d.dozuki.com/Wiki/Bed_levelling_using_multiple_independent_Z_motors#Section_Example_for_3_motors

Ian

-

Ive gone back through it and changed the config however I keep getting g30: some computed corrections exceed limit of 5.00.

Ive tried changing the limit, you see in some videos distances of 20+ mm, and it just seems to get ignored.

M671 X480:230.0:-30 s100 Y460.0:-40:460 S100

-

@mattbaker your m671 doesn’t look right.

Here’s mine. For reference the order of the z axis motors are one on the left is motor one, motor on the back right is two, motor on the front right is the third. All commands are listed/referenced with that order. I also always include a pin map in the beginning of my config.g as an easy reference.

; Configuration file for Duet3 (firmware version 3.0 RC2)

; executed by the firmware on start-up

;

; --------------- Pin/connection Mapping Legend -------------------

; out0 - Bed heater

; out1 - Extruder 1 heater

; out2

; out3

; out4 - Radiator cooling fan - WC heatsink

; out5

; out6

; out7

; out8 - Parts cooler on printhead

; out9 - Duet board cooling fan

; out4.tach - Radiator cooling fan rpm wire - WC heatsink

; out5.tach

; out6.tach

; io0.in

; io1.in - X min active low endstop switch

; io2.in - Y max active low endstop switch

; io3.in - Z probe type to bltouch - DEPRECATED

; io4.in - Z probe type to PIEZO

; io5.in - Emergency stop switch

; io6.in

; io7.in

; io8.in

; io0.out

; io1.out

; io2.out

; io3.out - GPIO port 0 on IO3, servo mode - BLTouch Z-Probe

; io4.out

; io5.out

; io6.out

; io7.out

; io8.out

; servo, out10 (only on v0.5, not on v0.6)

; pson

; spi.cs0

; spi.cs1

; spi.cs2

; spi.cs3

; temp0 - Bed Thermistor

; temp1 - PT1000 for extruder 1

; temp2 - PT1000 for pi4

; temp3

; mcu-temp - MCU sensor

;

; -----------------------------------------------------------------

;

; General preferencesG4 P2000 ; Hold your Horses.

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

G21 ; Set units to Millimeters

M550 P"DUET3" ; set printer nameM584 X0.3 Y0.2 Z0.0:0.1:0.4 E0.5 ; set drive mapping to each axis

M669 K1 ; Select CoreXY mode - New format; Network

M552 S1 ; enable network

M552 P192.168.3.120 ; Static IP Address

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0.0 S0 ; physical drive 0 goes backwards - Z Axis Left (1)

M569 P0.1 S0 ; physical drive 1 goes backwards - Z Axis Right Back (2)

M569 P0.2 S0 ; physical drive 2 goes backwards - Y Axis

M569 P0.3 S0 ; physical drive 3 goes backwards - X Axis

M569 P0.4 S0 ; physical drive 4 goes backwards - Z Axis Right Front (3)

M569 P0.5 S1 ; pyhsical drive 5 goes forwards - Extruder 1; Set up three Z-axis location

M671 X-52.5:377.5:377.5 Y162.5:282.5:42.5 S5 ; leadscrews at 1 - left, 2 - rear right and 3 - front rightM92 X200.00 Y200.00 Z400.00 E1800 ; set steps per mm

M350 X16 Y16 Z16 E16 I1 ; configure micro-stepping with interpolation

M566 X1000.00 Y1000.00 Z400.00 E240.00 ; set maximum instantaneous speed changes (mm/min)

M203 X24000.00 Y24000.00 Z2000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X10000.00 Y10000.00 Z400.00 E800.00 ; set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in percent*100

M572 D0 S0.074 ; Set pressure advance

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X320 Y320 Z350 S0 ; set axis maxima; Endstops

M574 X1 S1 P"io1.in" ; X min active high endstop switch

M574 Y2 S1 P"io2.in" ; Y max active high endstop switch; Z-Probe - BLTouch - DEPRECATED

; M574 Z1 S2 ; set endstops controlled by probe

; M558 P9 C"^io3.in" H3 F60000 T10000 ; set Z probe type to bltouch and the dive height + speeds (bltouch NEEDS pullup)

; G31 P10 X28.5 Y-5 Z2.35 ; set Z probe trigger value, offset and trigger height; Z-Probe - PIEZO

M574 Z1 S2 ; set endstops controlled by probe

M558 P8 C"io4.in" H5 F1000 T20000 ; set Z probe type to PIEZO and the dive height + speeds

G31 P10 X0 Y0 Z-0.1 ; set Z probe trigger value, offset and trigger heightG30 ; Probe Z

; Configure Heaters and Sensors

M308 S0 P"temp0" Y"thermistor" A"Bed Temp" T100000 B3950 ; Configure bed temperature sensor

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"temp1" Y"pt1000" A"Extruder 1 Temp" ; Configure extruder 1 temperature sensor - PT1000 sensor

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M308 S2 P"mcu-temp" Y"mcu-temp" A"Duet Board" ; Configure MCU sensor

; M308 S4 P"temp2" Y"pt1000" A"RPI" R2200 ;Pt1000 temp sensor for the raspberry pi; Define Sensors and Fans

M950 H0 C"out0" T0 ; Define heater 0 (bed heater) - bed_heat pin and Temp Sensor 0

M950 H1 C"out1" T1 ; Define heater 1 (hot-end E0) to use the "e0_heat" pin and Temp Sensor 1;Set PID values

M307 H0 A253.9 C566.2 D1.0 V23.3 B0 ; disable bang-bang mode for the bed heater and set PWM limit

M307 H1 A855.8 C368.4 D5.7 V23.3 B0 ; disable bang-bang mode for the extruder heater and set PWM limitM950 F0 C"out8" Q100 ; Define Fan_0 for use - Parts Cooler on Printhead - 4010 fan

M950 F1 C"!out4+^out4.tach" Q25000 ; Define Fan_1 for use - Radiator cooling - WC heatsink. - PWM fan

M950 F2 C"out9" Q25000 ; Define Fan_2 for use - Duet board cooling fan

; M950 S0 C"io3.out" ; Define GPIO port 0 on IO3, servo mode - BLTouch Z-Probe - DEPRECATED; Fans

M106 P0 S0 ; set fan 0. Parts Cooler on Printhead

M106 P1 T25:40 H2 ; Set fan 1. Manages Radiator fan for water-cooled loop.

M106 P2 T35:50 H2 ; Set fan 2. Manages Duet board fan.; Tools

M563 P0 S"Extruder 1" D0 H1 F0 ; define tool 0. Fan 0 operates with an active hot-end

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C; Emergency Stop

M574 S1 P"^!io5.in" ; Define Emergency endstop - emergency stop switch condition

M581 P"io5.in" T0 ; Define action to be taken with activation of emergency stop switch; Miscellaneous

T0 ; select first tool

M501 ; Store parameters -

@Nuramori Thanks for your help. I uploaded new files from the configurator, changed a few things, which I thought is what I had, and problem solved.

No idea what the problem was, looks the same to me, but I'm not going to look a gift horse in the mouth.